A modified cotton fiber for infants based on liquid freezing

A technology for infants and modified cotton, which is applied in the fields of plant fiber, fiber treatment, textiles and papermaking, etc. It can solve the problems of decreased hygroscopicity and achieve the effects of reduced shrinkage, good softness, low viscosity and surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

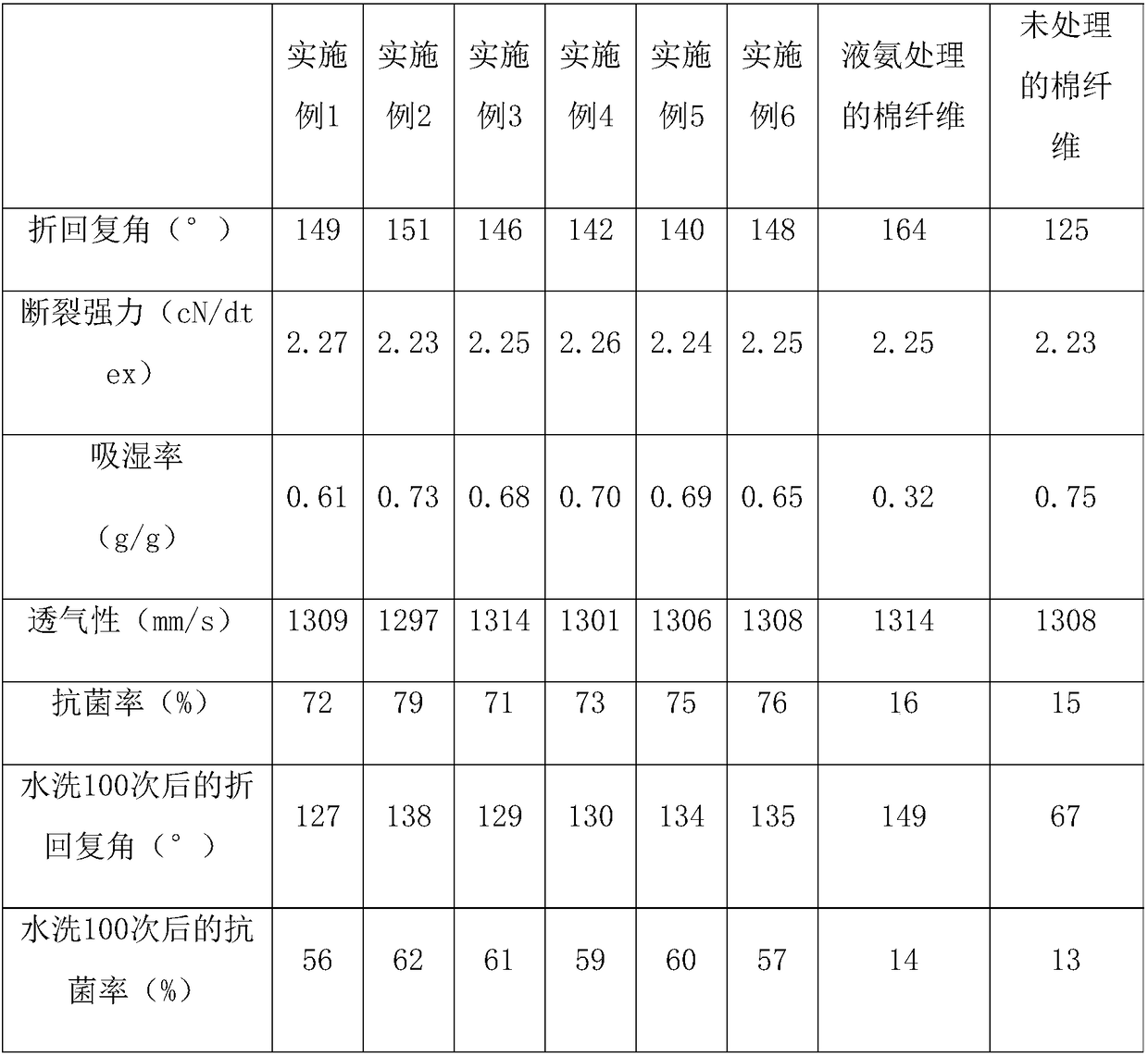

Examples

Embodiment 1

[0028] (1) After the cotton fibers are removed from the surface impurities, they are immersed in deionized water, taken out and aired to obtain cotton fibers with a moisture content of 20%, and the moisture-containing cotton fibers are placed in a subzero-10°C environment to freeze to obtain pretreated cotton fibers. fiber.

[0029] (2) Put the pretreated cotton fiber prepared in step (1) into the sarong of the liquid ammonia treatment tank, vacuumize, and process 2 times through intermittent and repeated liquid ammonia treatment, wherein the intermittent and repeated liquid ammonia treatment includes dispensing a sufficient amount of liquid ammonia Immerse the cotton fiber for 10s, drain the ammonia and pump out the ammonia gas, and remove the ammonia by microwave for 3min at a power of 50kW to obtain the cotton fiber treated by liquid freezing.

[0030] (3) the cotton fiber of the liquid freezing treatment that step (2) is prepared is placed in the chitosan treatment liquid ...

Embodiment 2

[0032] (1) After the cotton fibers are removed from the surface impurities, they are immersed in deionized water, taken out and aired to obtain cotton fibers with a moisture content of 60%, and the hydrated cotton fibers are placed in a subzero-20°C environment to freeze to obtain pretreated cotton fibers. fiber.

[0033] (2) Put the pretreated cotton fiber prepared in step (1) into the sarong of the liquid ammonia treatment tank, vacuumize, and process 3 times through intermittent and repeated liquid ammonia treatment, wherein the intermittent and repeated liquid ammonia treatment includes dispensing a sufficient amount of liquid ammonia Immerse the cotton fiber for 20s, drain the ammonia and pump the ammonia gas, and remove the ammonia by microwave at 80kW power for 5min to obtain the cotton fiber treated by liquid freezing.

[0034] (3) the cotton fiber of the liquid freezing treatment that step (2) is prepared is placed in the chitosan treatment liquid with a bath ratio of...

Embodiment 3

[0036] (1) After the cotton fibers are removed from the surface impurities, they are immersed in deionized water, taken out and dried to obtain cotton fibers with a moisture content of 50%, and the hydrated cotton fibers are placed in a subzero-15°C environment to freeze to obtain pretreated cotton fibers. fiber.

[0037] (2) Put the pretreated cotton fiber prepared in step (1) into the sarong of the liquid ammonia treatment tank, vacuumize, and process 2 times through intermittent and repeated liquid ammonia treatment, wherein the intermittent and repeated liquid ammonia treatment includes dispensing a sufficient amount of liquid ammonia Immerse the cotton fibers for 15s, drain the ammonia and pump out the ammonia gas, and remove the ammonia by microwave at 60kW power for 4min to obtain the cotton fibers treated by liquid freezing.

[0038] (3) the cotton fiber of the liquid freezing treatment that step (2) is prepared is placed in the chitosan treatment liquid with a bath ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com