Plant transfer printing cloth and preparation method thereof

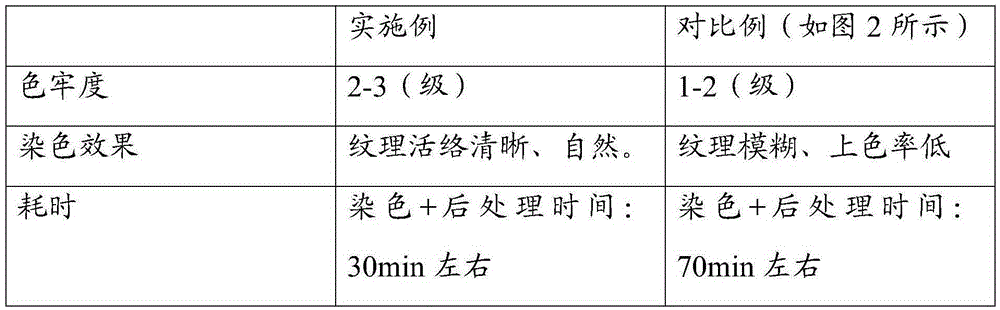

A plant and pad printing technology, applied in the field of textile printing and dyeing, can solve the problems of high labor cost, low color yield, complicated boiling and dyeing, etc., and achieve the effect of clear and fast context.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] A method for preparing plant pad printing cloth, comprising the steps of:

[0024] Soak the plants and flowers in the mordant aqueous solution (soaking time is 1min), then lay the soaked plants and flowers on the gray cloth according to the set position, and press (5-10 seconds); wherein the mordant in the mordant aqueous solution Concentration is 5 / L, and described mordant is potassium aluminum sulfate;

[0025] Arrange the above-mentioned blanks after pressing pad printing in a plant dyeing vat for conventional dyeing; wherein the composition of the plant dyeing vat includes logwood, the dyeing temperature is 40°C (the dyeing temperature should not be too high), and the dyeing time is 5-10 minutes;

[0026] Soaping (the temperature of soaping is 60°C, and the time of soaping is 5min), hot water washing (the temperature of hot water washing is 60°C, and the time of hot water washing is 5min), and then peracid post-treatment (pH value is 6.0) , to obtain the plant pad ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com