A pipe jacking construction method

A construction method and pipe jacking technology, which is applied in the direction of earthwork drilling, mining equipment, tunnels, etc., can solve the problems that "V"-shaped longitudinal curve pipe jacking construction cannot be applied, and achieve large construction slope, high economic efficiency, and high construction efficiency. safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The invention provides a pipe jacking construction method to solve the technical problem that the pipe jacking method in the prior art cannot be applied to the pipe jacking construction of a large-slope "V"-shaped longitudinal curve.

[0048] The technical solution in the embodiment of the present application is to solve the above-mentioned technical problems, and the general idea is as follows:

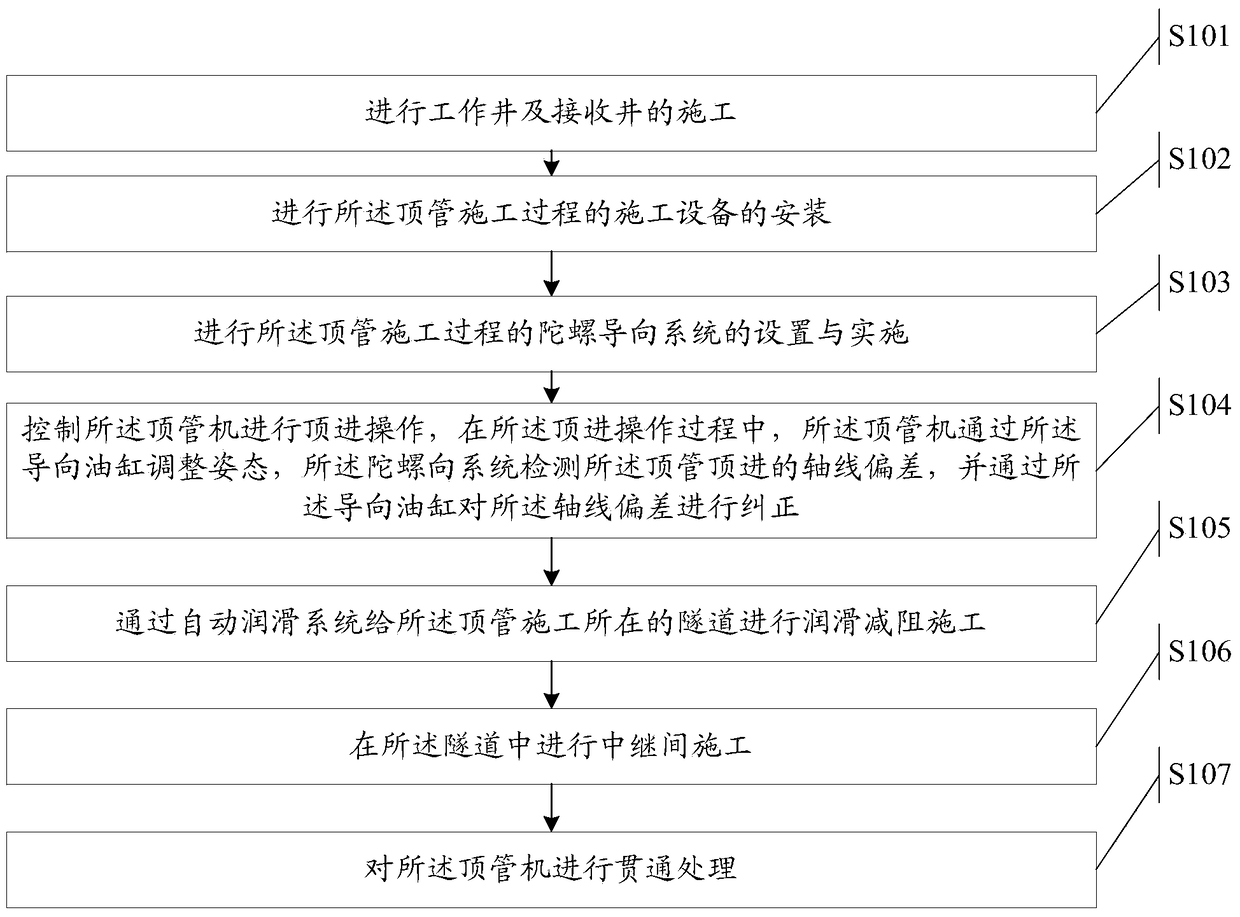

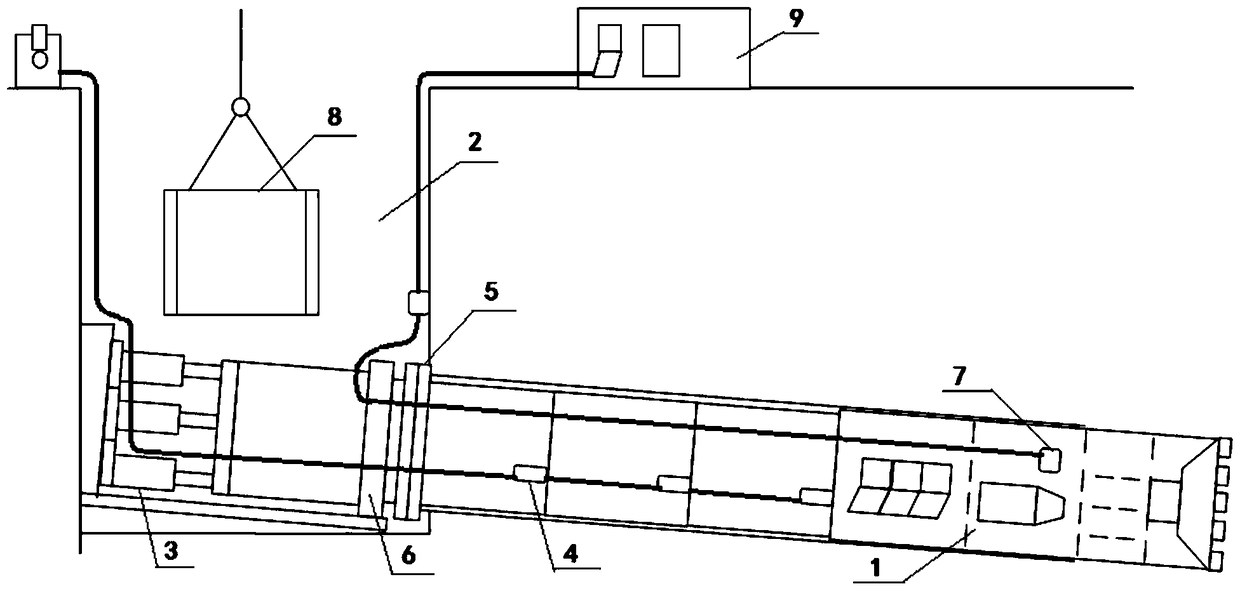

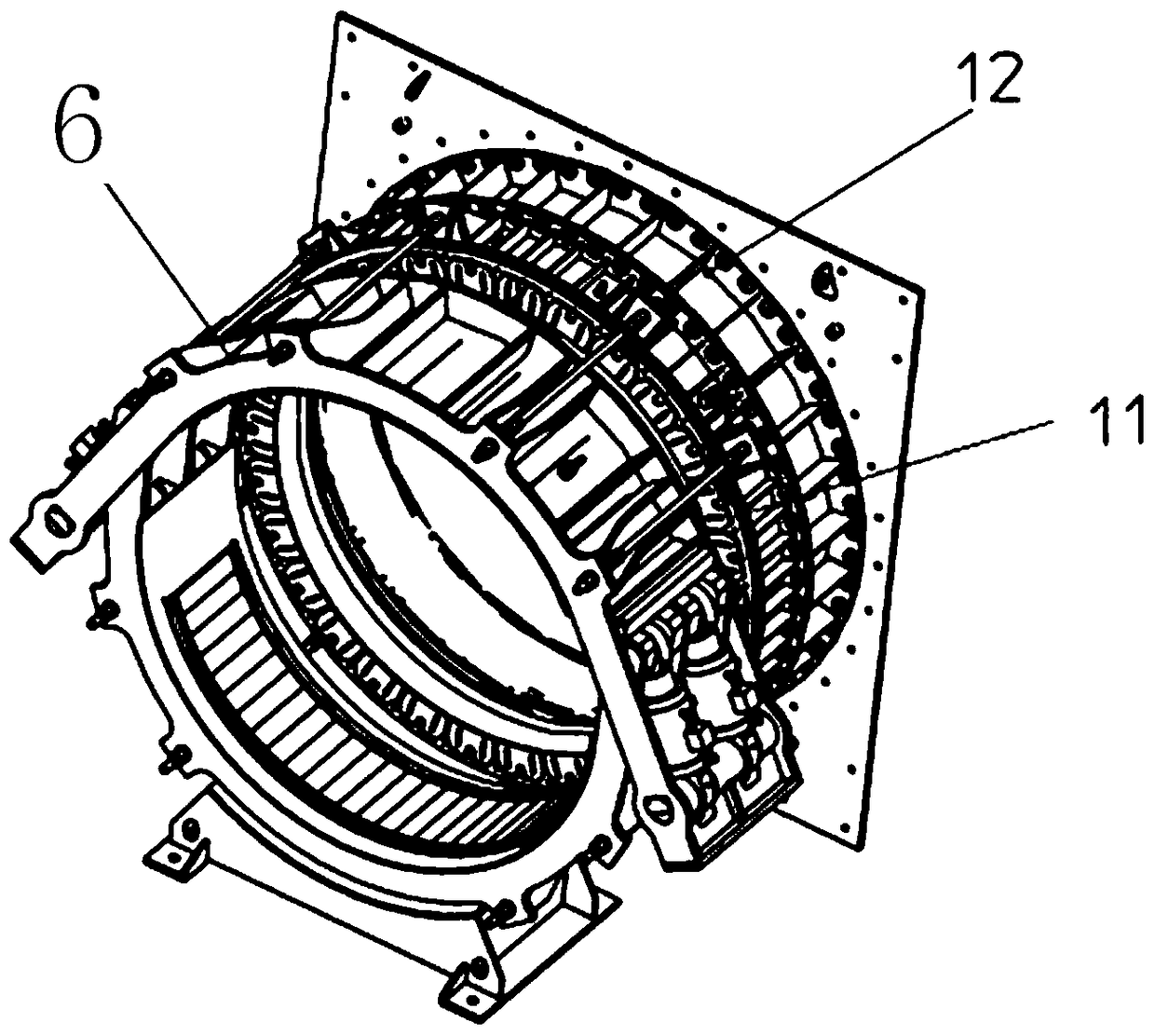

[0049]A pipe jacking construction method is provided, including: carrying out construction of a working well and a receiving well; and installing construction equipment for the pipe jacking construction process, wherein the construction equipment includes: a pipe jacking machine, a door sealing device and Pipe joint stop device; wherein, the pipe jacking machine is a muddy water pressurized balanced pipe jacking machine, and the pipe jacking machine is equipped with a rock cutting and crushing device, an air pressure chamber and a guide cylinder; the door sealing device include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com