Optical lens capable of rapid positioning

A technology of optical lenses and lenses, applied in the field of optical lenses, can solve the problems of cumbersome positioning of optical lenses, achieve fast and convenient positioning, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following briefly describes the content of the accompanying drawings used in the embodiments of the present invention, wherein:

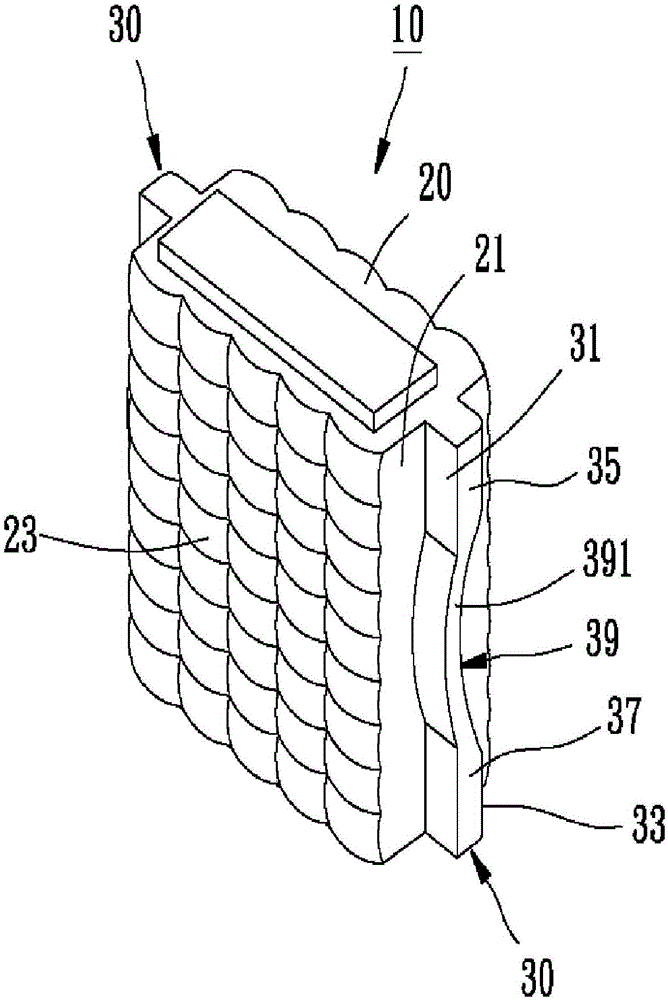

[0020] figure 1 It is a perspective view showing an optical lens according to a preferred embodiment of the present invention;

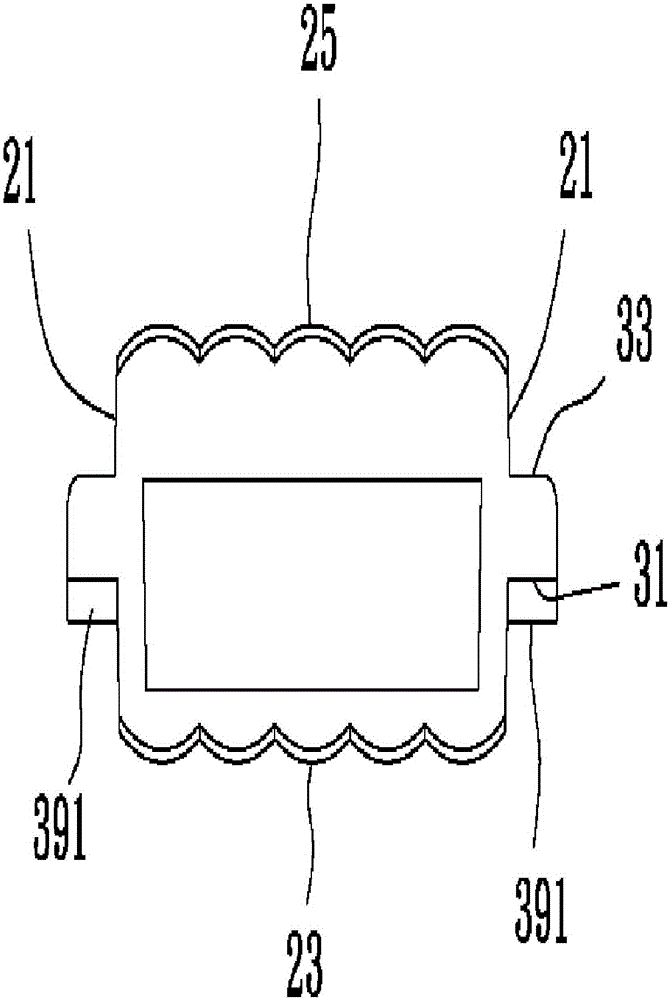

[0021] figure 2 It is a top view showing that the two positioning flanges of the optical lens of the preferred embodiment have protrusions;

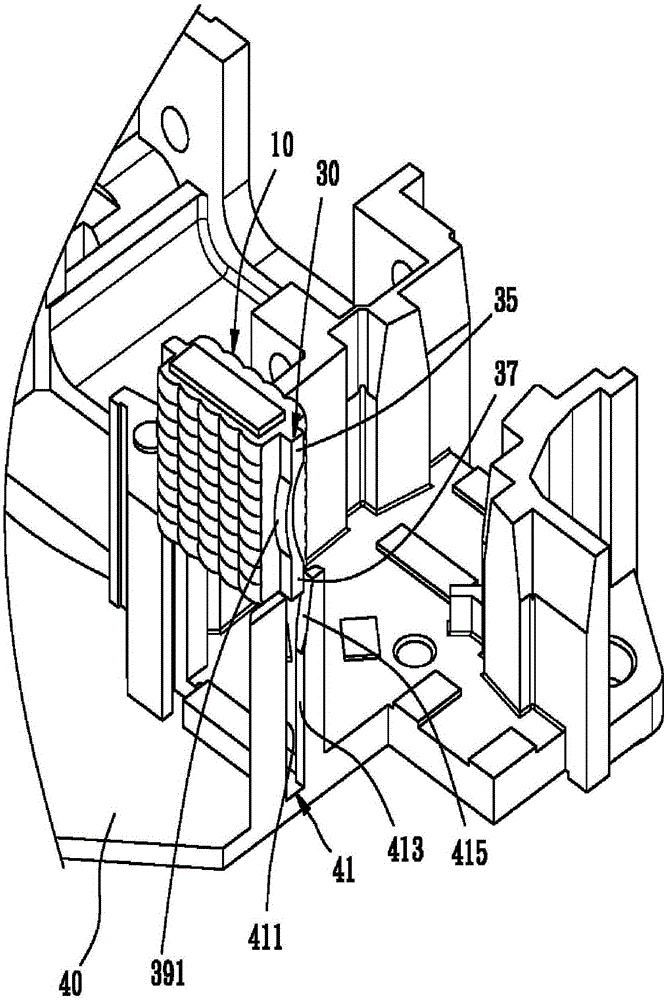

[0022] image 3 It is a three-dimensional exploded view showing that the optical lens of the preferred embodiment has not been installed in the projector body and the state of the insertion groove of the projector body; and

[0023] Figure 4 It is a three-dimensional view showing that the optical lens of the preferred embodiment is positioned in the groove of the projector body.

[0024] First please refer to Figure 1 to Figure 2 , the optical lens 10 provided by a preferred embodiment of the present invention mainly includes a lens body 20 and two positioning fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com