Textile wet processing apparatus

A wet treatment, fabric technology, applied in the field of textile fabric devices, can solve problems such as the inability to accommodate lighter or smaller diameter cloth ropes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

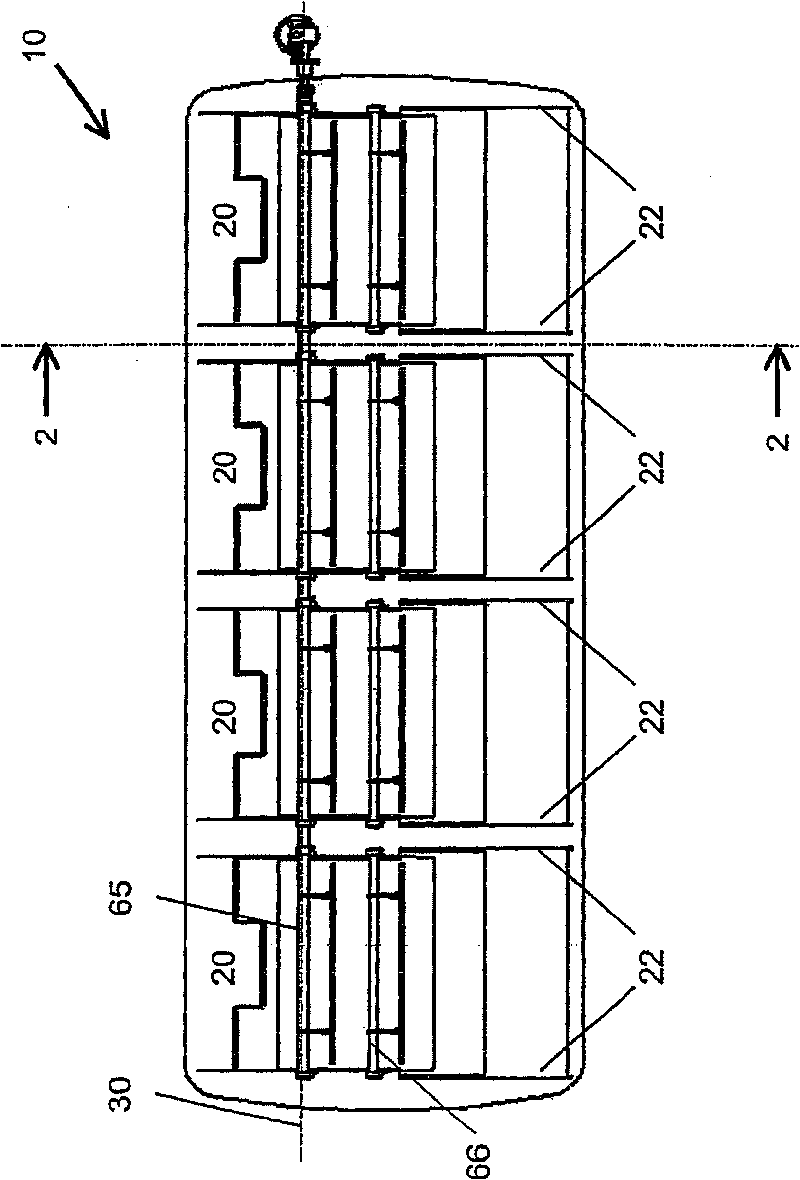

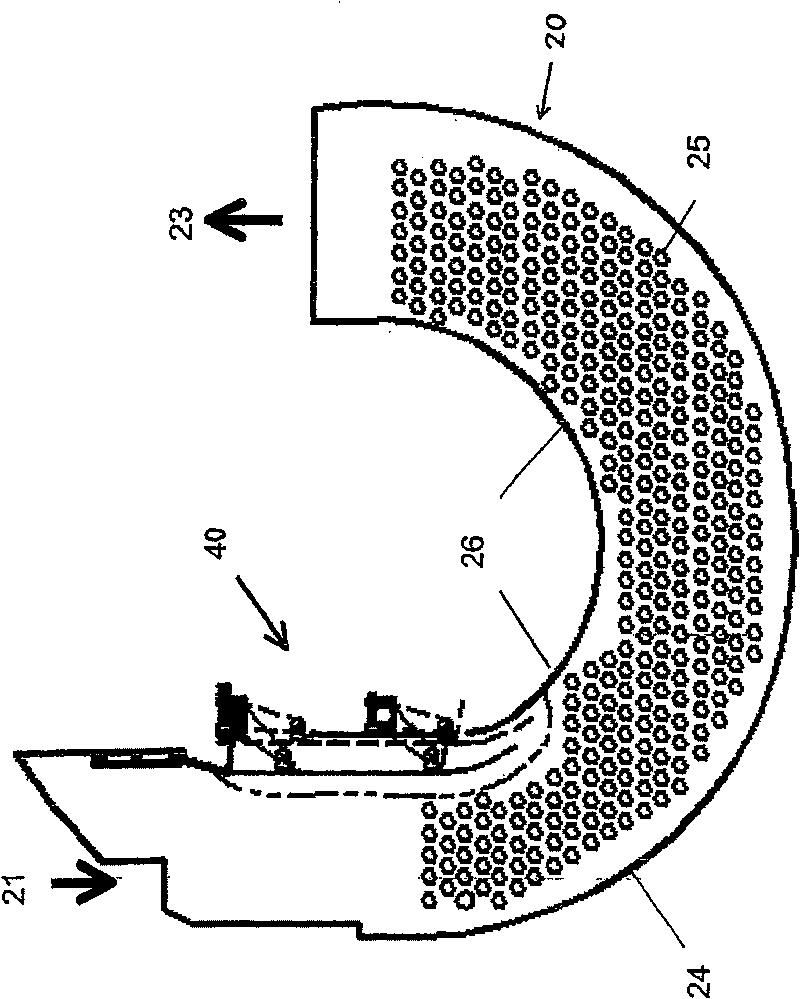

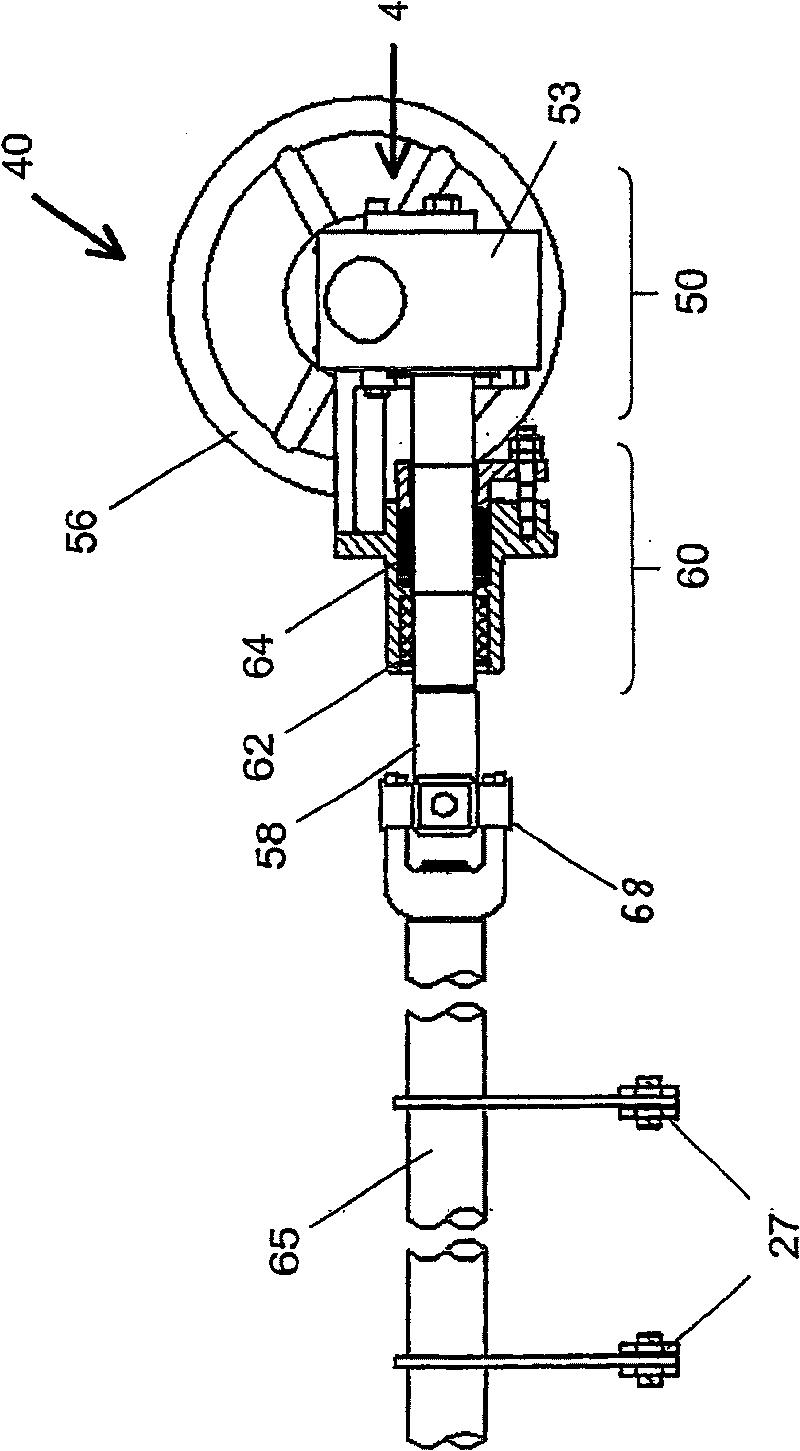

[0026] A preferred embodiment of the present invention provides a treatment chamber for a fabric wet treatment machine. It includes means for adjusting the volumetric dimensions of the treatment chamber. Fabric wet processing machines include processing chambers with adjustable inner walls to accommodate textile fabrics in the form of ropes having different characteristics such as weight, texture, thickness and load. The inner wall can be quickly and easily positioned at any position relative to the chamber wall between a predetermined innermost position and a predetermined outermost position. The adjustment of the position of the inner wall relative to the outer wall changes the volumetric size of the treatment chamber and this enables the fabric wet treatment machine to achieve a maximum treatment capacity for the treatment of individual textile fabrics.

[0027] Therefore, referring to the accompanying drawings, the fabric wet treatment machine is only schematically shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com