Stair deflection testing tool

A technology for testing tooling and steps, which is applied in the direction of measuring devices, testing of machines/structural components, instruments, etc., can solve problems such as complex structure, inconvenient installation, and inability to meet step tests, and achieve high versatility, easy movement, and increased versatility The effect of sex and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

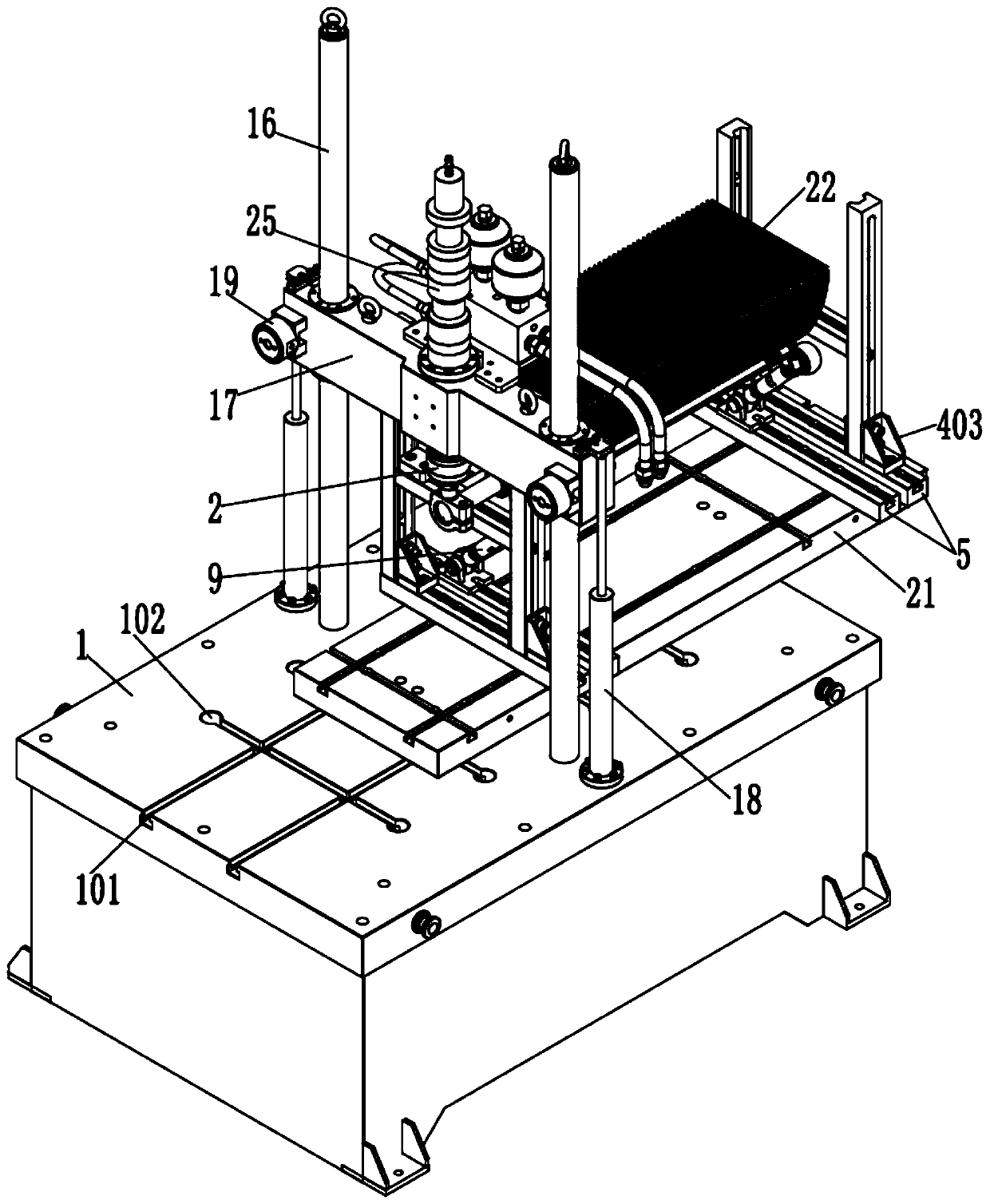

[0046] Such as Figure 1-Figure 14 A step deflection test tooling shown includes a workbench 1, a clamping mechanism, a support mechanism, a test drive mechanism, a sensor 2 and a step indenter head 3; the support mechanism is installed on the upper surface of the workbench 1, and the The test driving mechanism is installed on the support mechanism, the sensor 2 is installed on the output end of the test driving mechanism, and the clamping mechanism is installed on the upper surface of the workbench 1. The clamping mechanism is used to limit the step parts, and the step pressure head Part 3 includes a joint bearing sleeve 301 and a final shaft 302, the joint bearing sleeve 301 is connected to the output end of the test drive mechanism, one end of the final shaft 302 is connected to the joint bearing sleeve 301, and the other end of the final shaft 302 is connected to the clamping mechanism connected, the sensor 2 is connected to the final shaft 302.

[0047] Such as Figure ...

Embodiment 2

[0066] This embodiment is the same as embodiment 1 except the following technical features:

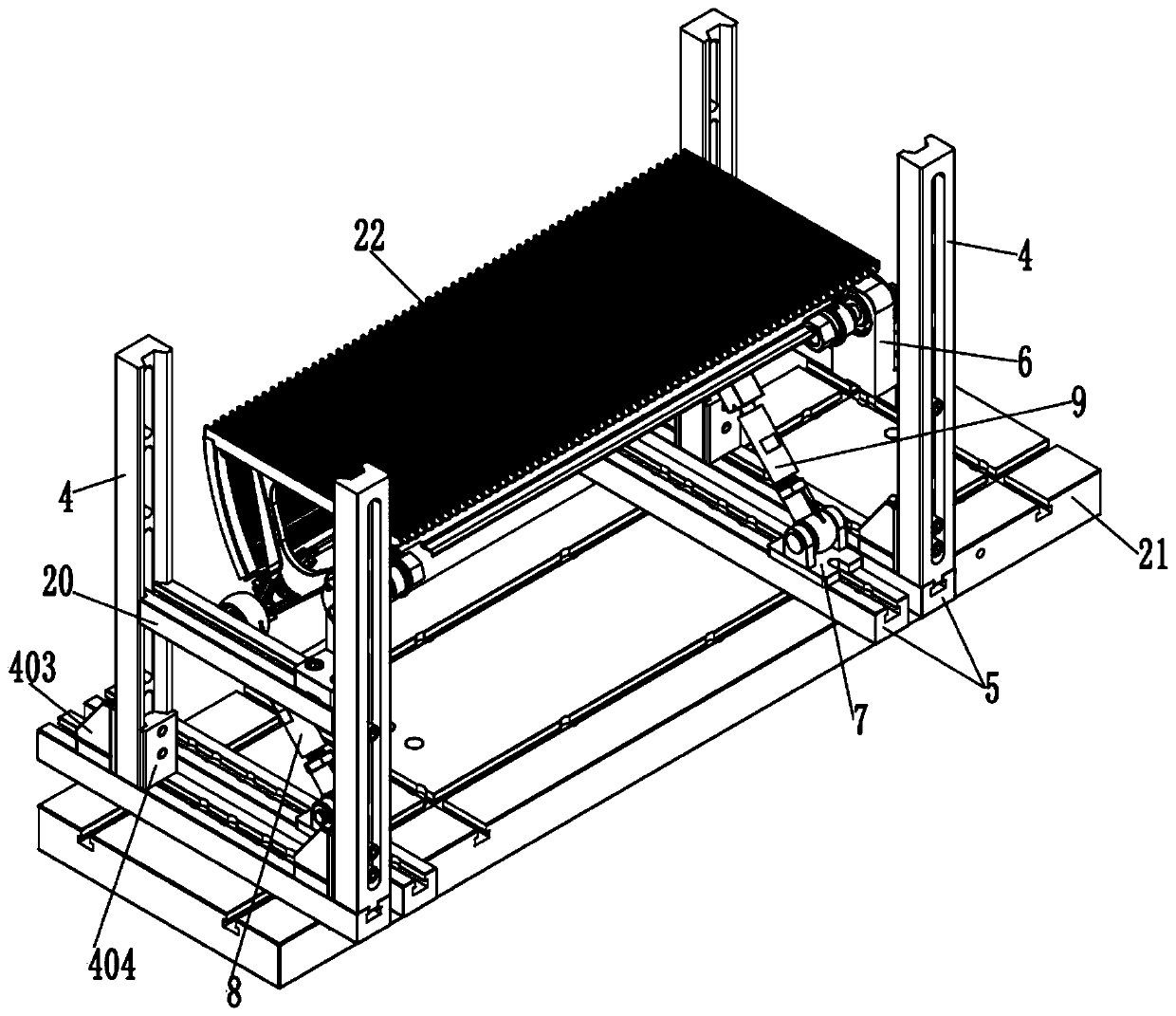

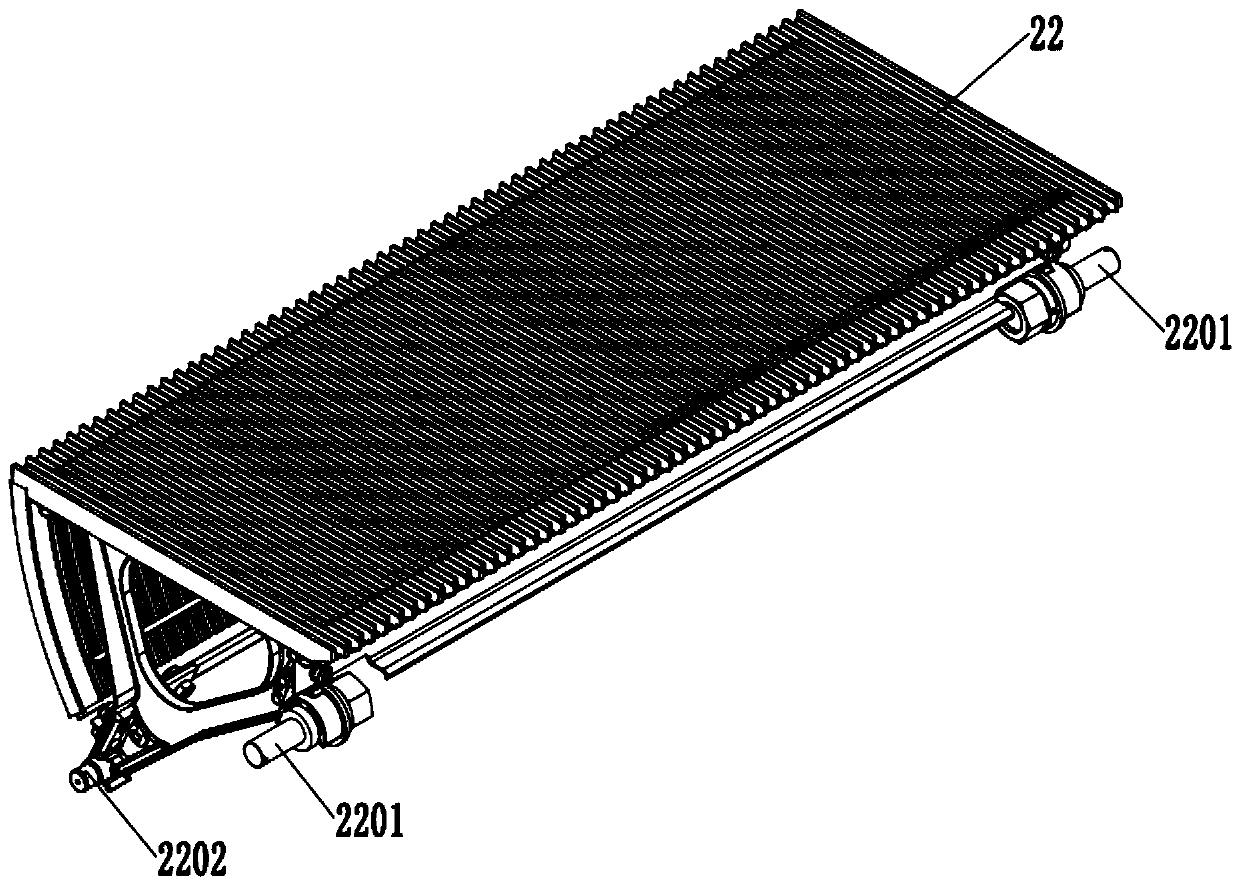

[0067] Such as Figure 15-23 As shown, the clamping frame includes a bottom support layer, a column 4 and a first beam 20; the bottom support layer is slidably arranged on the workbench 1, and two columns 4 are relatively installed on the bottom support layer. The two ends of the first beam 20 are respectively connected with the two uprights 4; the clamping assembly includes the second beam 10, the rocker arm 11, the second chain shaft positioning seat 12, the wedge-shaped locking member 13, and the first roller seat 14, the second supporting roller seat frame 24 and the sliding iron 15; the bottom support layers of the two clamping frames are equipped with the first supporting roller seat frame 14, and the two ends of the second beam 10 are clamped with one of them The two columns 4 of the frame are connected, the second beam 10 is located above the first beam 20 of the clamping fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com