Injection molded shoe midsole with grooves and manufacturing method thereof

A manufacturing method and technology for injection molding shoes, which are applied to shoe soles, footwear, clothing, etc., can solve the problems of increasing manufacturing costs, increasing manufacturing costs, and prolonging, and achieve the effect of extending the delivery time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

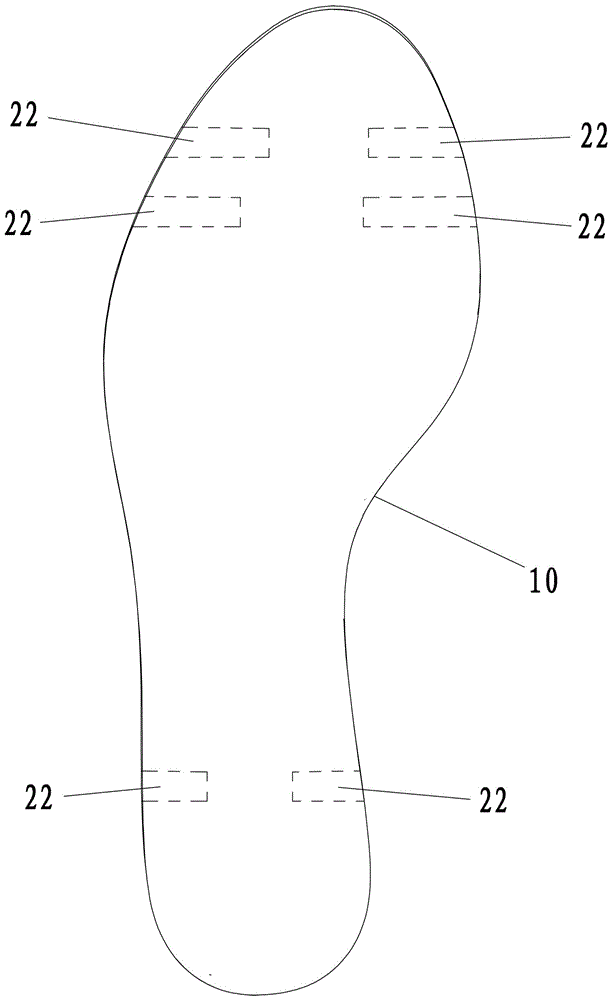

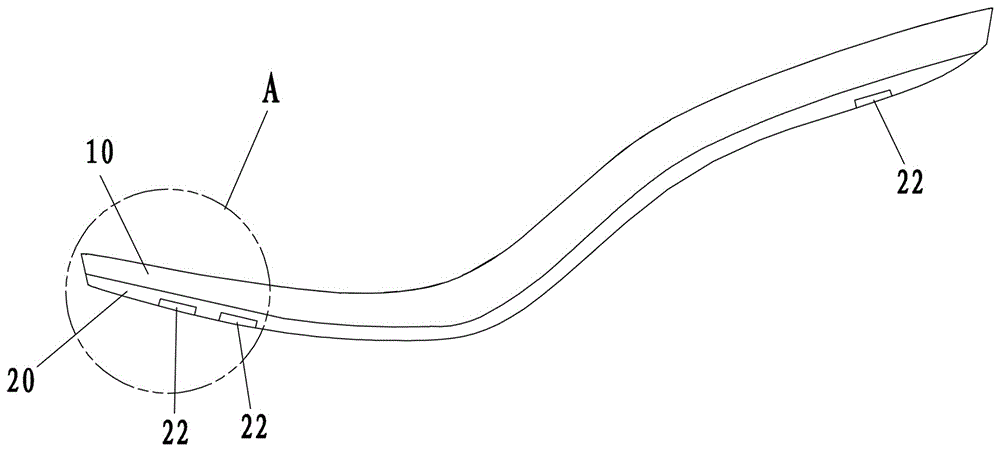

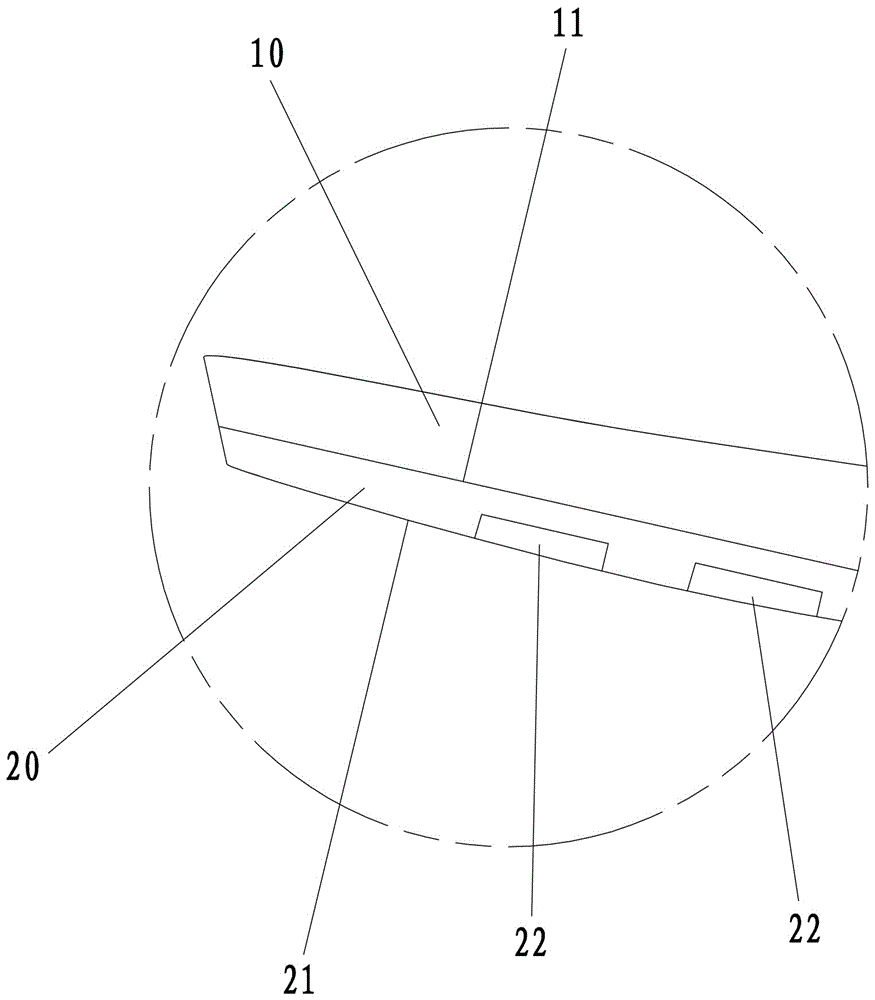

[0043] see figure 1 , 2 3. The injection molded shoe midsole with grooves of the present invention includes an injection molded shoe midsole main body 10, the lower surface 11 of the shoe midsole main body is attached with a groove plate 20 which is solidly integrated with it during injection molding, and the groove The peripheral portion of the lower surface 21 of the plate is provided with a groove 22 with an opening, and the groove 22 is used to accommodate the end of the strip. The depth of the concave groove 22 is 1.5 mm, and the thickness of the groove plate 20 is 3 mm. mm, the concave top surface of the groove 22 and the lower surface 11 of the shoe midsole body are spaced by the groove plate 20 above the groove 22, so that when the shoe midsole body 10 is injection molded, the glue is drawn by the groove 22 The upper groove plate 20 blocks and cannot enter into the groove 22 .

[0044] The manufacturing method of the above-mentioned injection molded shoe midsole with...

Embodiment 2

[0049] see Figure 4 , 5 , the injection molded shoe midsole with grooves of the present invention comprises an injection molded shoe midsole main body 10, the lower surface 11 of the shoe midsole main body is attached with a groove plate 20 which is solidly integrated with it during injection molding, and the groove plate 20 is composed of Composed of an integrated upper partition 23 and a lower slot 24, the upper partition 23 is attached to the lower surface 11 of the shoe midsole body during injection molding, the lower slot 24 is located below the upper partition 23, and the lower slot 24 Peripheral part is provided with the through groove 25 that has opening up and down, and this through groove 25 is used for accommodating and placing the end of strip; The concave depth of the groove formed with the upper floor dividing plate 23 is 1.5 millimeters, and the total thickness of the groove plate 20 formed by the combination of the upper floor dividing plate 23 and the lower ...

Embodiment 3

[0057] see Figure 6 , 7 , the present invention has grooved injection molded shoe midsole, comprises injection molded shoe midsole main body 10 and channel plate 20, and shoe midsole main body 10 is the middle rear part of shoe midsole, and channel plate 20 is divided into the head and connects as An upper plate 26 and a lower plate 27 that are integrated and separated up and down at the tail, and the integrated head of the groove plate 20 is the front part of the midsole of the shoe. The upper plate 26 and the lower plate 27 are attached to the main body of the midsole of the shoe during injection molding. The upper surface 12 and the lower surface 11 of the main body of the midsole of the shoe; the thickness of the upper plate 26 is 0.75 millimeters, the thickness of the lower plate 27 is 2.25 millimeters, and the peripheral portion of the lower surface 28 of the lower plate is provided with a groove 22 with an opening. Groove 22 is used for accommodating and placing the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com