Water dispenser with water receiving tray capable of being lifted automatically

An automatic lifting and water tray technology, applied in beverage preparation devices, household appliances, applications, etc., can solve the problems of wasting water resources, the distance between faucets cannot be adjusted, and water splashing, so as to save water resources and prevent accidental burns Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

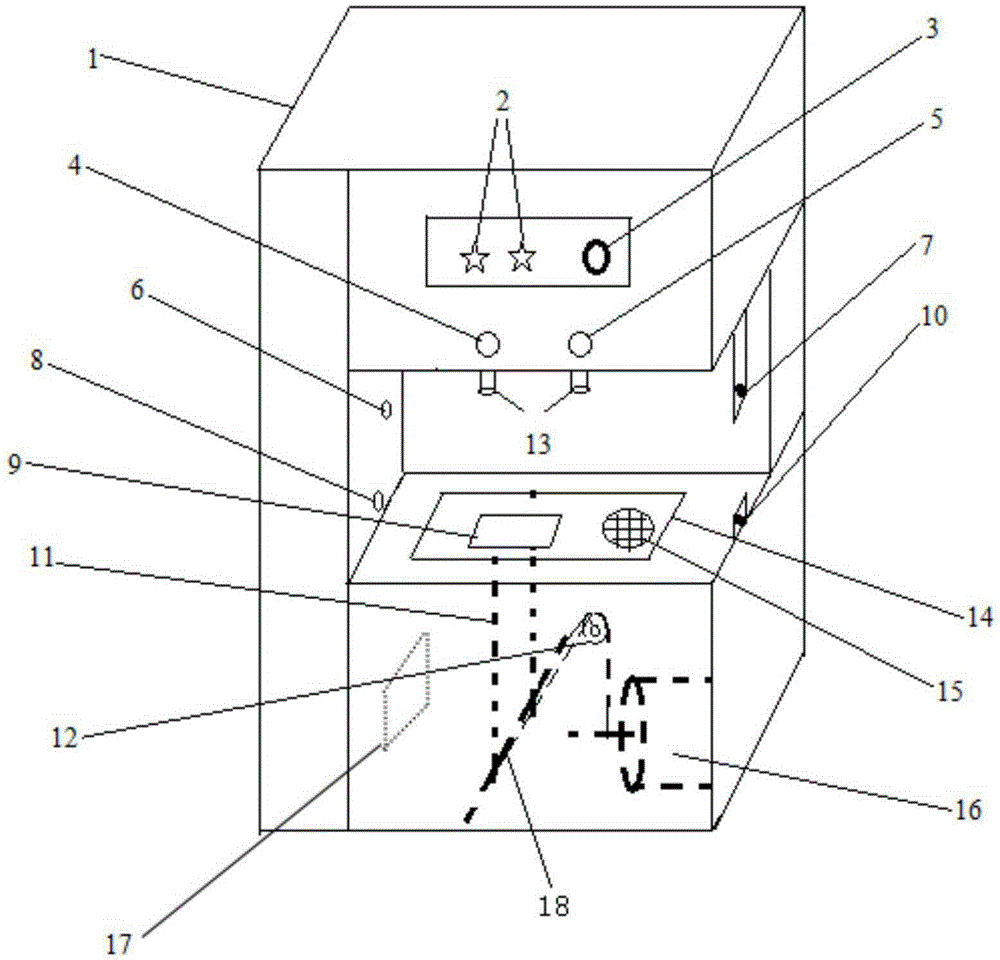

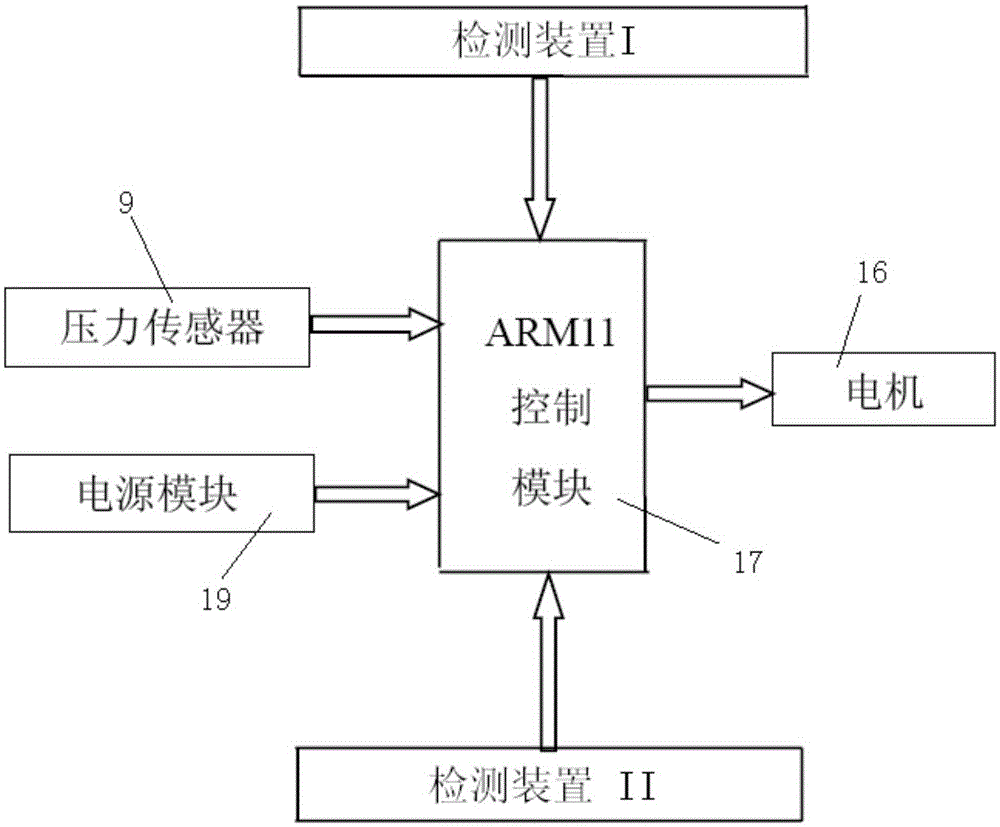

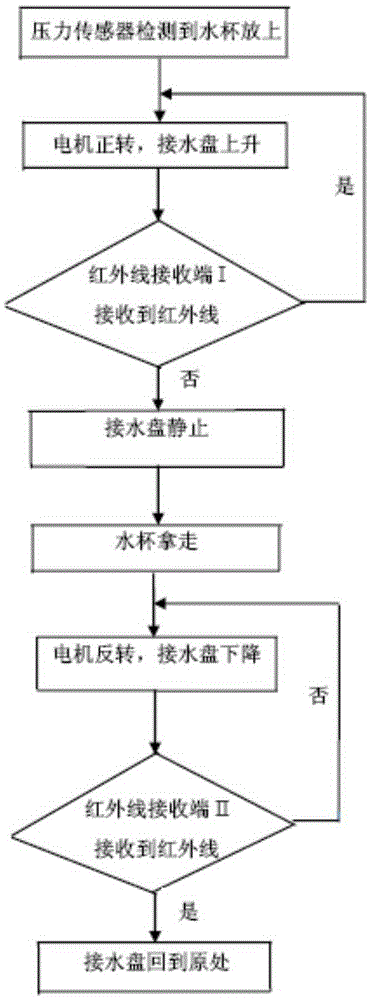

[0029] As an implementation, the detection device 1 includes an infrared transmitting terminal I6 and an infrared receiving terminal I7, the infrared transmitting terminal I6 and the infrared receiving terminal I7 are respectively connected to the control module 17, and the infrared transmitting terminal I6 The infrared receiving end I7 is respectively arranged on the opposite side wall of the housing 1, and the water receiving tray 14 is located between the infrared emitting end I6 and the infrared receiving end I7. In the case of no obstruction, the infrared receiving end I7 can receive the infrared rays emitted by the infrared emitting end I6.

[0030] As an implementation, the detection device II includes an infrared transmitting terminal II8 and an infrared receiving terminal II10, the infrared transmitting terminal II8 and the infrared receiving terminal II10 are respectively connected to the control module 17, and the infrared transmitting terminal II8 and the infrared ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com