A busbar floating conical mirror polishing device

A technology of polishing device and conical mirror, which is applied in grinding drive device, grinding/polishing equipment, optics, etc., can solve the problems of low price, incapable of polishing disc, no design of conical mirror polishing machine, etc., and meet the requirements of lowering , wear uniformity, ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

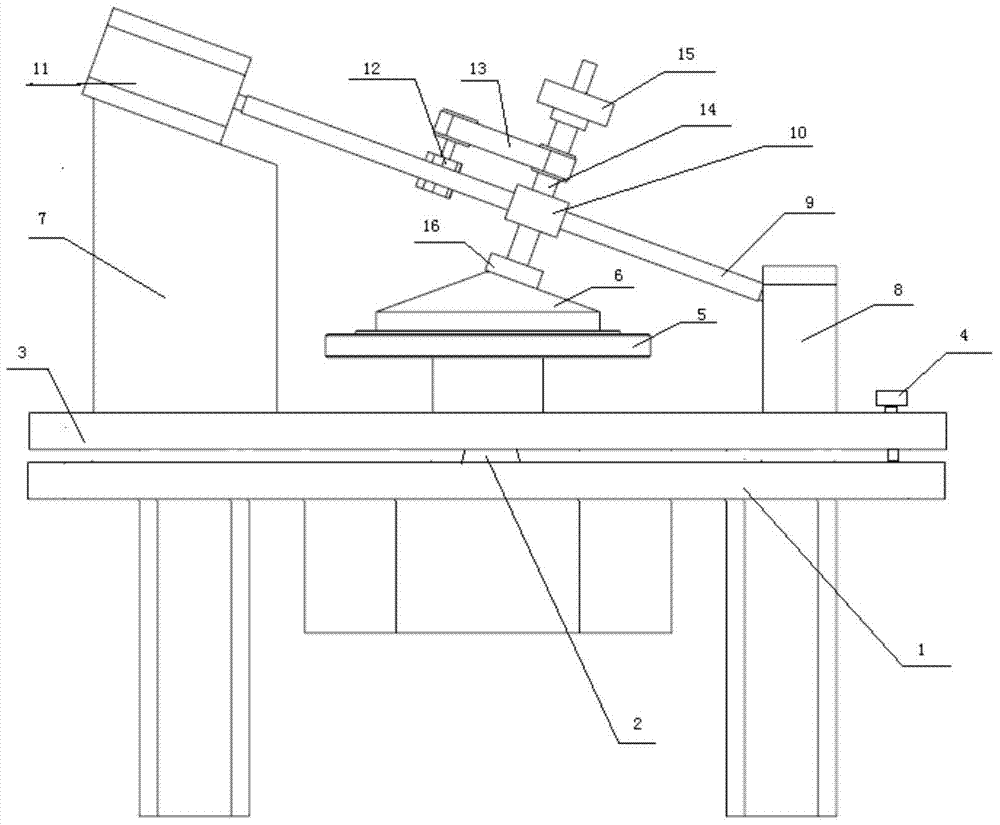

[0025] according to figure 1 A busbar floating conical mirror polishing device shown includes a power system, a busbar floating system and a polishing system. The power system includes a power frame 1, and the conical power shaft 2 of the power frame 1 extends out of the table to connect the workpiece The turntable 5 and the tapered power shaft 2 drive the workpiece turntable 5 to rotate. For the transformation of the power frame 1 that can provide rotating power, only the table surface that the tapered power shaft 2 protrudes out of the frame is guaranteed.

[0026] The busbar floating system includes a floating disc 5 suspended on the power rack table. The center of the floating disc 5 has an avoidance hole for avoiding the tapered power shaft 3. The two sides of the floating disc 5 are provided with guide rail supports, which are respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com