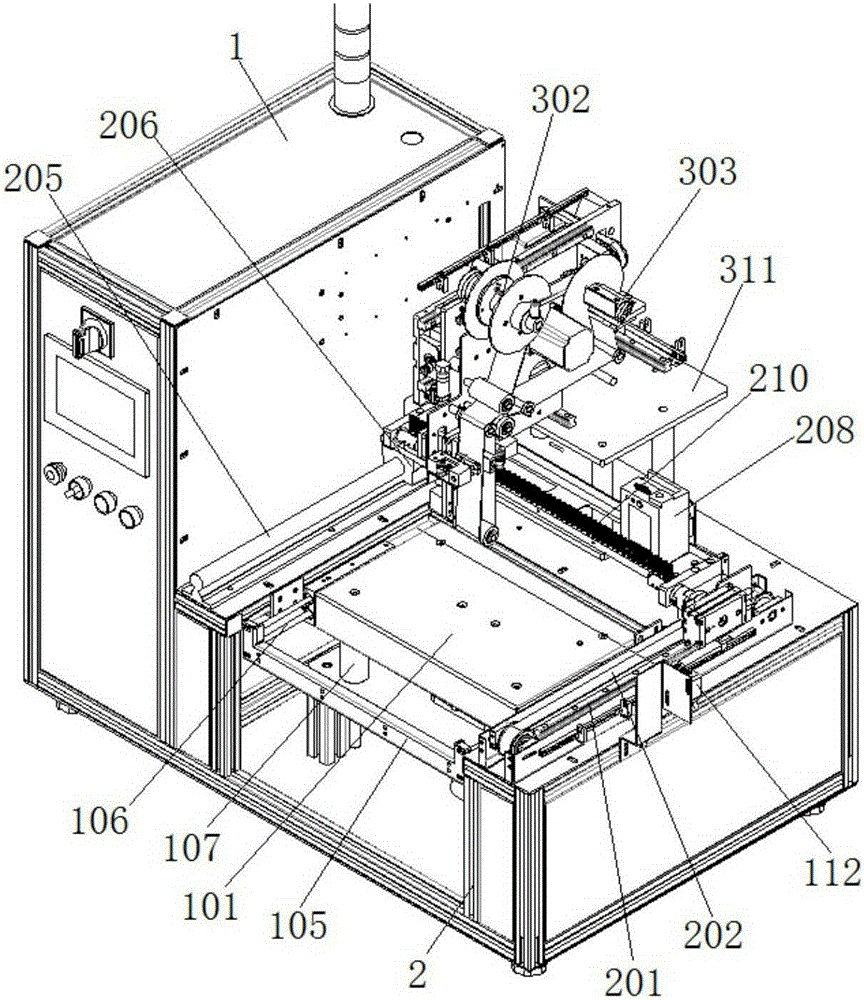

Encoding piece turning mechanism with automatic cut piece numbering machine

An automatic numbering and piece cutting technology, applied in the field of garment processing, can solve the problems of wasting labor costs, high error probability, and low efficiency, and achieve the effect of reducing labor costs and improving numbering efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

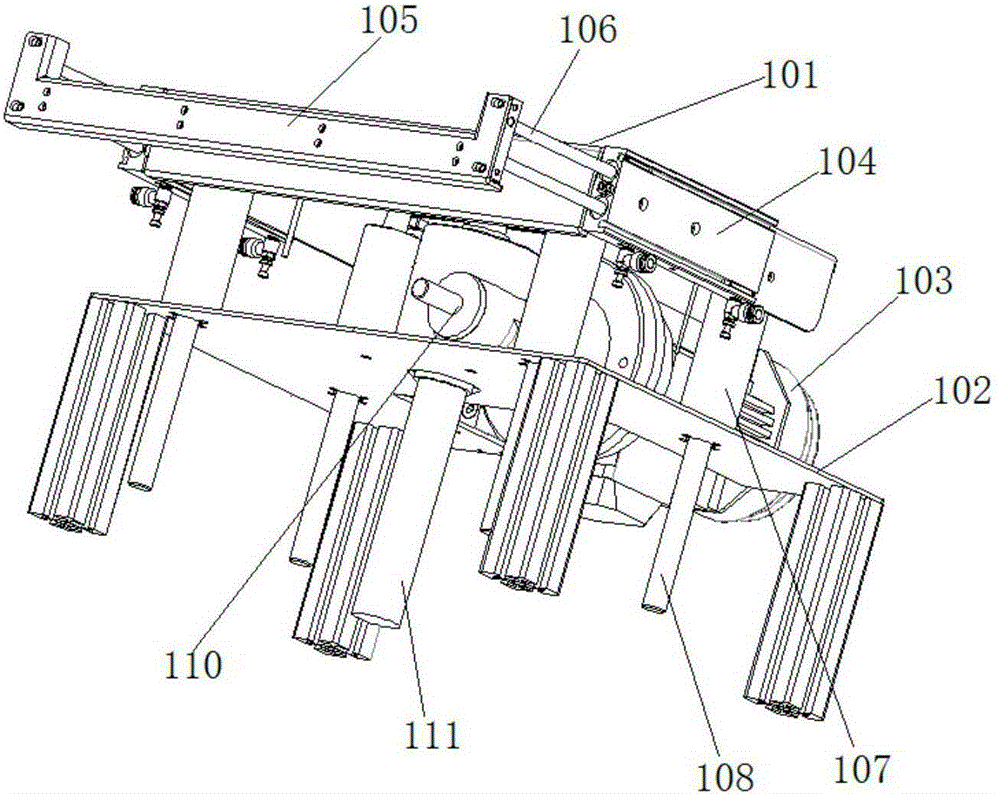

[0025] 1) The encoding mechanism adopts the coding method:

[0026] The coding mechanism includes a coding device. The coding device is like a coding machine. The coding device moves up and down (such as a stamp), so that the coding device numbers the cut pieces on the feeding table 101.

[0027] 2) The coding mechanism adopts the coding method:

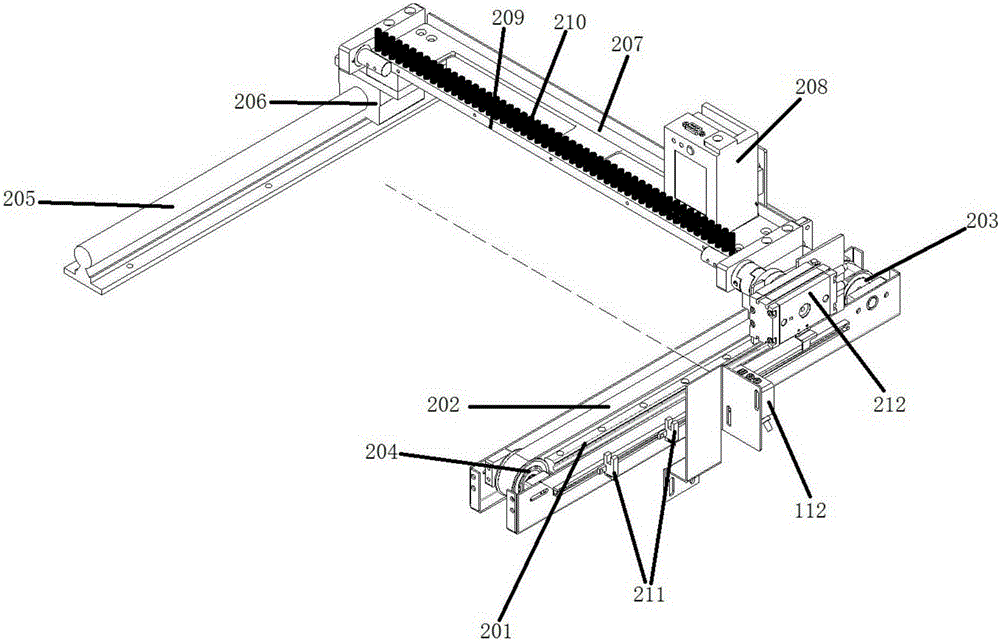

[0028] Such as image 3 As shown, the coding mechanism includes a coding device 208 (using a coding machine) and a power device that drives the motion of the coding device 208. The pieces are numbered.

[0029] The power unit comprises a first guide rail and a second guide rail, and the first guide rail and the second guide rail are respectively arranged on both sides of the placement mechanism. The first guide rail includes a guide rail 201 for a guide and a fixed element and a sliding block for a moving element, and the second guide rail includes a guide rail for a guide and a fix element. Track 205 and moving element slide blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com