Built-in V tail vane surface driving mechanism

A drive mechanism, built-in technology, applied in aircraft parts, aircraft control, transportation and packaging, etc., can solve problems such as inability to modularize design and troublesome installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

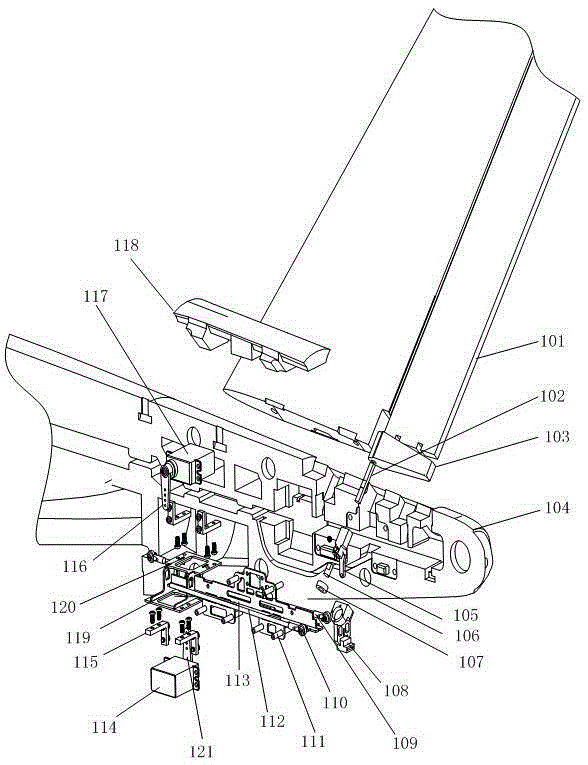

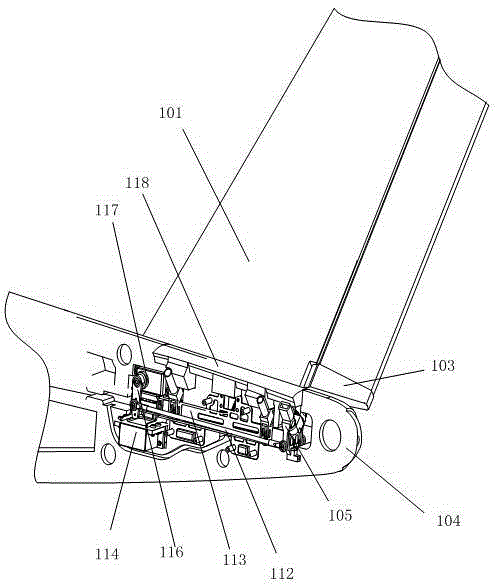

[0016] This embodiment provides a built-in V-tail rudder surface drive mechanism, such as figure 1 and figure 2 As shown, the built-in V-tail rudder surface driving mechanism includes a fuselage 104 and a rudder surface 101, wherein an integral frame 113 is fixedly arranged in the fuselage, and the integral frame 113 is provided with a steering gear placement position 119 and a steering gear placement position 120, wherein , the steering gear placement position 119 is used to install the steering gear 114, and the steering gear placement position 120 is used to install the steering gear 117, and each steering gear is connected to the first rotating arm, wherein the first rotating arm is a steering gear piece, for example, The steering gear 117 is connected with the steering gear piece 116 .

[0017] The overall frame 113 is also equipped w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com