Large-bearing low-impact connecting and separating device based on memory alloy driving

A technology for connecting and separating devices and memory alloys is applied in the field of connecting and separating devices driven by memory alloys to achieve the effects of reliable separation, shortened response time of unlocking and separation, and high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

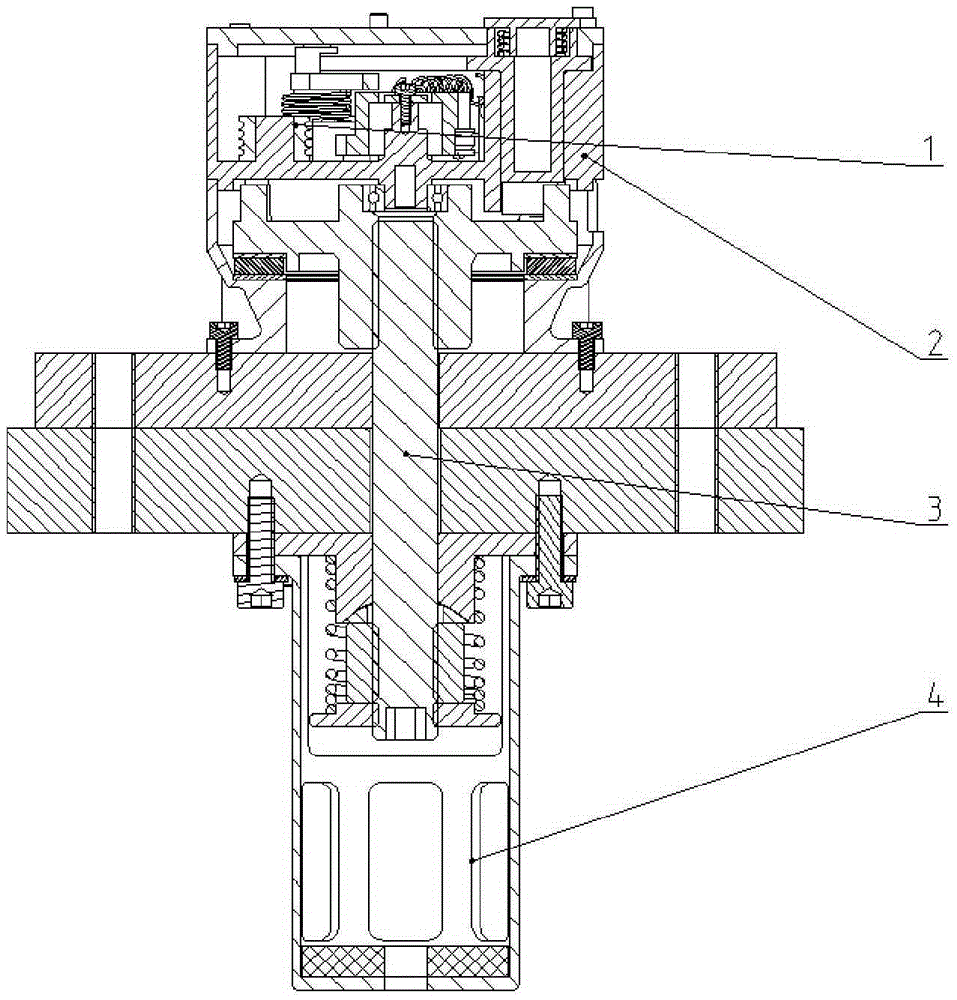

[0021] Such as figure 1 As shown, the present invention provides a large-load low-impact connection and separation device based on a memory alloy drive, including: a memory alloy drive assembly 1 , an unlocking transmission assembly 2 , a connection and separation assembly 3 , and a buffer capture assembly 4 .

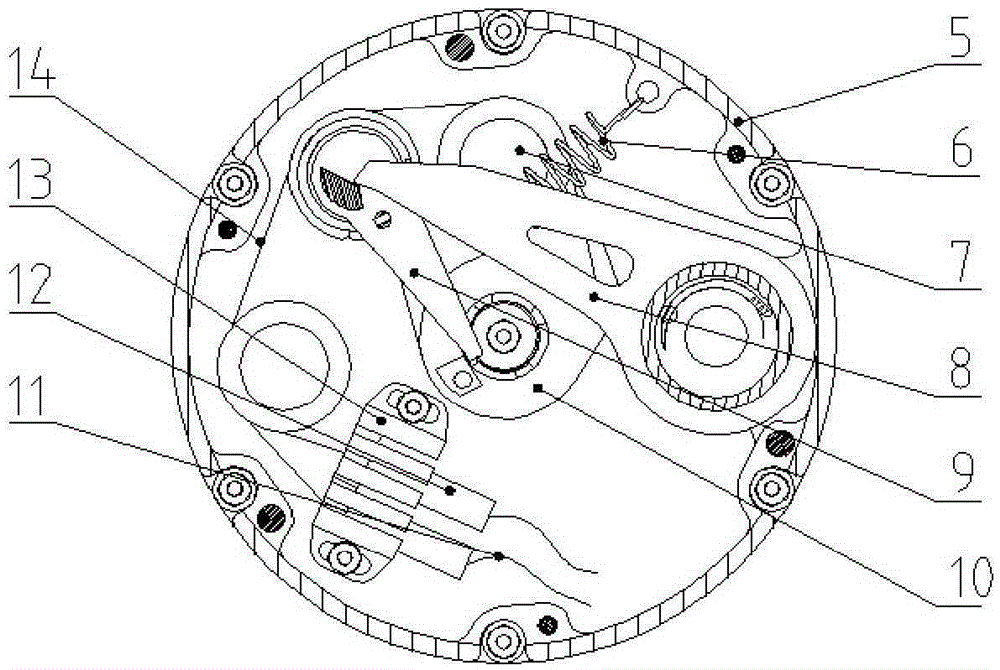

[0022] Such as figure 2 As shown, memory alloy driving assembly 1 includes memory alloy wire 14, crimping terminal 12, wire 11, terminal mounting base 13 and steering ring 7; the front end wire loop formed after memory alloy wire 14 is folded in half is connected with trigger shaft 10, and the tail end The crimping terminal 12 is connected to the wire 11, and the terminal mounting base 13 fixes the crimping terminal 12 on the transmission housing 5; the steering ring 7 is distributed along the circumference of the transmission housing 5, and the memory alloy wire 14 is embedded in the side of the steering ring 7 In the positioning groove, the memory alloy wire 14 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com