A bottle feeding device

A technology of receiving device and discharging device, which is applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problems of low production efficiency, low speed of receiving materials, and narrow scope of application, and achieve fast receiving speed and contact Small area and low resistance of guide bottle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Now in conjunction with accompanying drawing, describe the present invention in detail.

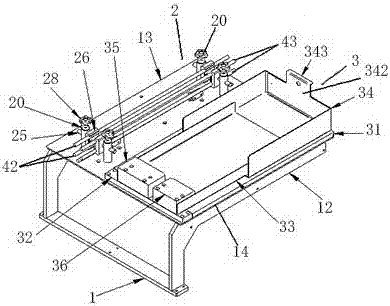

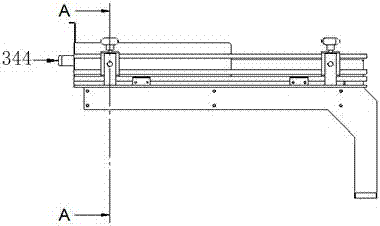

[0034] Refer to attached Figure 1~4 , a bottle discharging and receiving device, comprising a bracket connecting plate 1, a discharging device 2 and a receiving device 3;

[0035] When in use, the bracket connecting plate 1 is installed on the frame of the main engine with bolts. The bottom of the bracket connecting plate 1 is provided with three horizontal support bars 11, and the bracket connecting plate 1 is provided with a platform support plate 12. On the platform support plate 12 There is a bottle-discharging panel, which is installed on the platform support plate 12 with screws. The bottle-discharging panel includes a left panel 13 and a right panel 14 arranged side by side. The discharging device 2 is placed on the left panel 13, and the receiving device 3 on the right panel 14;

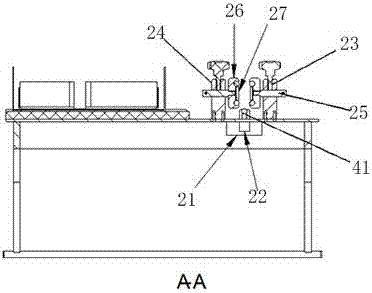

[0036] The discharge device 2 includes a mounting seat 21, an adjustment mounting seat grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com