Manual detection auxiliary device for continuous production line of tubular products or bars

A technology of manual detection and auxiliary devices, which is applied in the direction of transportation and packaging, conveyors, mechanical conveyors, etc., can solve the problems of difficult arrangement of artificial tube/bar detection stations, affecting the production rhythm of the production line, and the arrangement of detection stations. , to achieve the effect of saving working time, improving production efficiency and reducing space constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

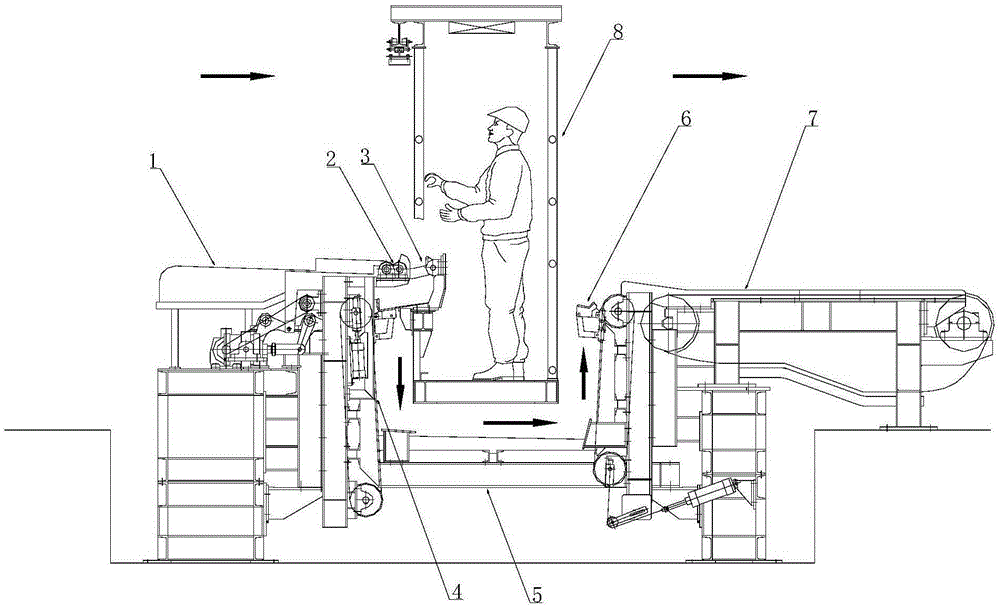

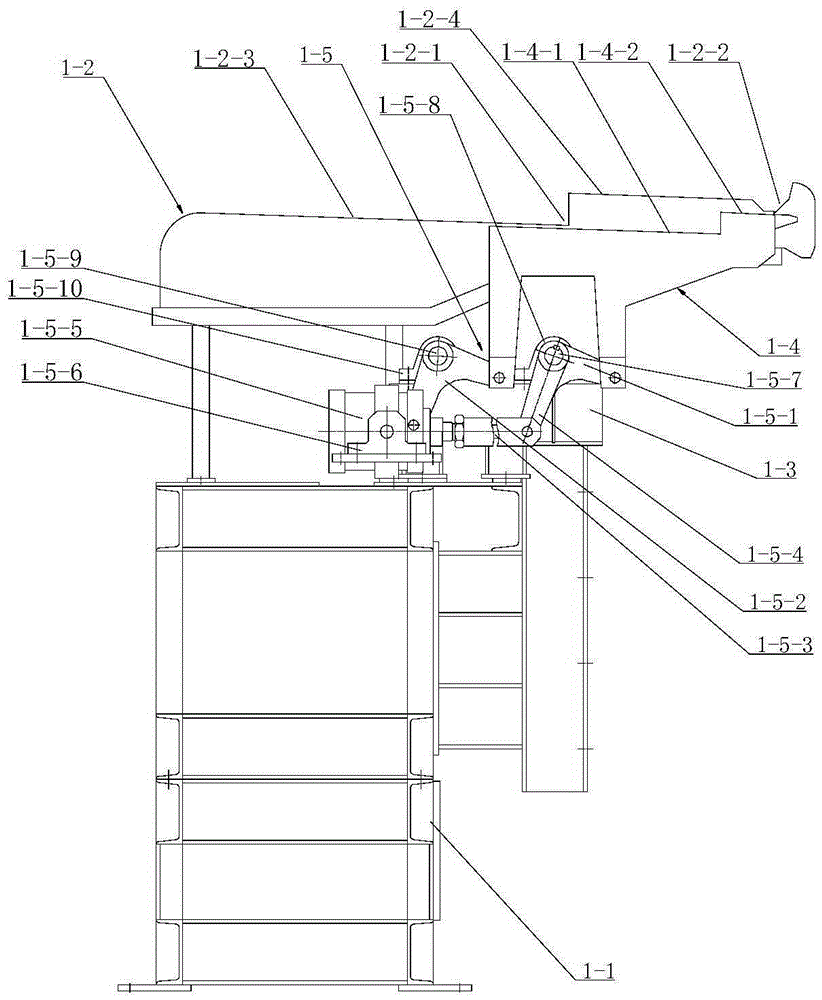

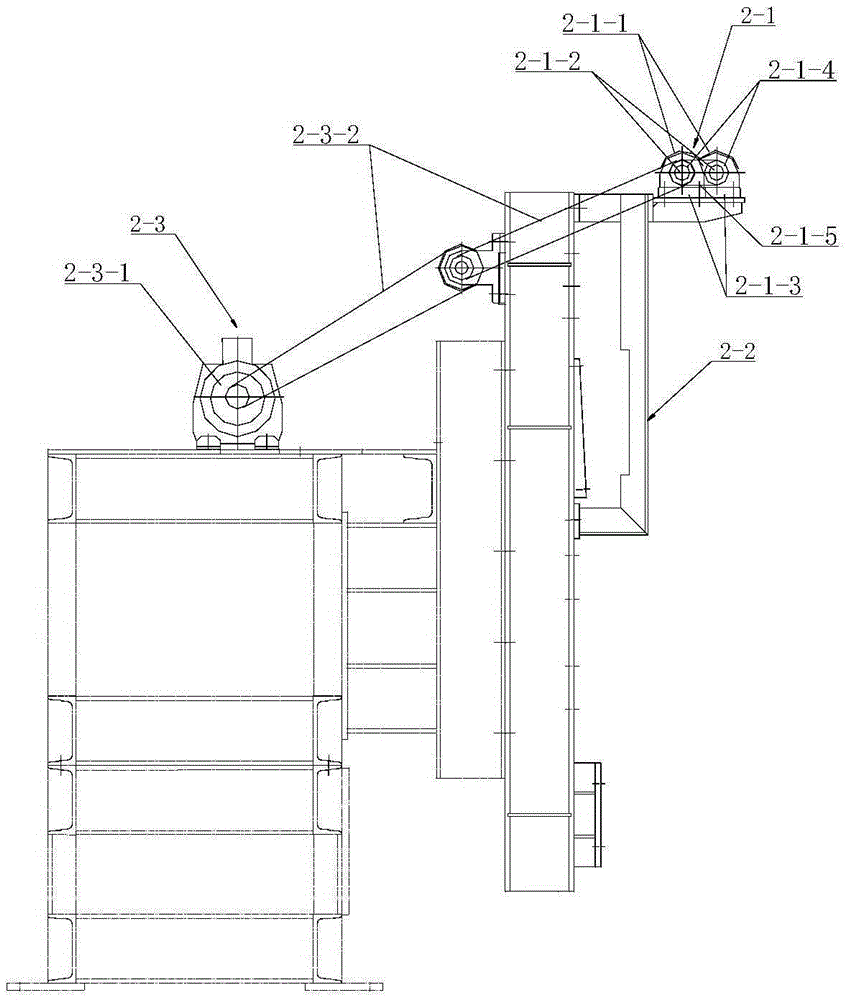

[0026] see Figure 1-9 , used for the manual detection auxiliary device on the continuous production line of pipes or rods. According to the conveying direction of the material, the manual auxiliary device includes a feeding mechanism 1, a detection wheel mechanism 2, a feeding mechanism 3, and a descending transmission mechanism 4 connected in sequence. , material transport mechanism 5, ascending conveying mechanism 6, material discharging mechanism 7, wherein a manual operation platform 8 is provided between the descending conveying mechanism and the ascending conveying mechanism, the manual operating platform is positioned at the top of the conveying mechanism, and the manual operating platform consists of The bracket 8-1, the top frame 8-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com