Machining method of knotting gun head

A processing method and ceramic core technology, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve problems such as unsafe accidents, wire damage, cost waste, etc., and achieve a solid overall structure, cost saving, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

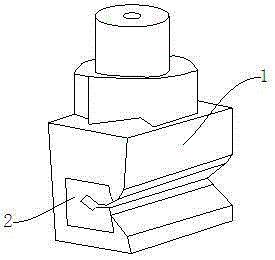

[0017] The invention provides a method for processing a knotted gun head, which includes the following steps: (a) opening a through hole for installation at the center of the gun head body 1; (b) forming a ceramic core 2 with a mold, and The shape matches the inner surface of the installation through hole; (c) install the ceramic core 2 in the installation through hole.

[0018] Referring to the accompanying drawings to describe the processing method of the knotted gun head of the present invention, figure 1 A knotted gun tip processed according to an embodiment of the present invention is shown, which includes a gun tip body 1, and a mounting through hole is opened at the center of the gun tip body 1, and a ceramic core 2 formed by a mold is installed in the mounting through hole . The ceramic core body 2 is provided with openings, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com