An environment-friendly load test coke oven and its application method

A test coke oven, environmental protection technology, applied in coke oven, petroleum industry, etc., can solve the problems of large deviation of cold strength strength index, environmental pollution, large deviation of test results, etc., to achieve automatic operation, convenient use, and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

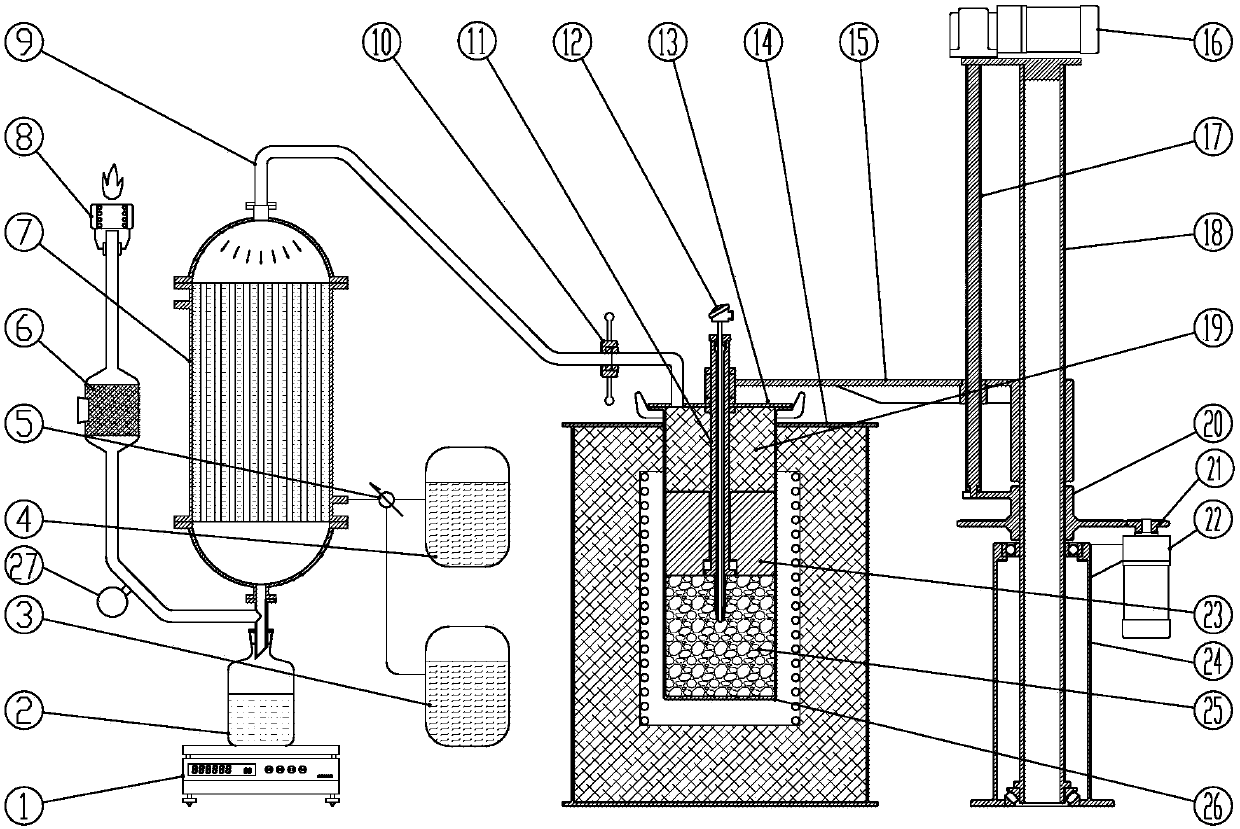

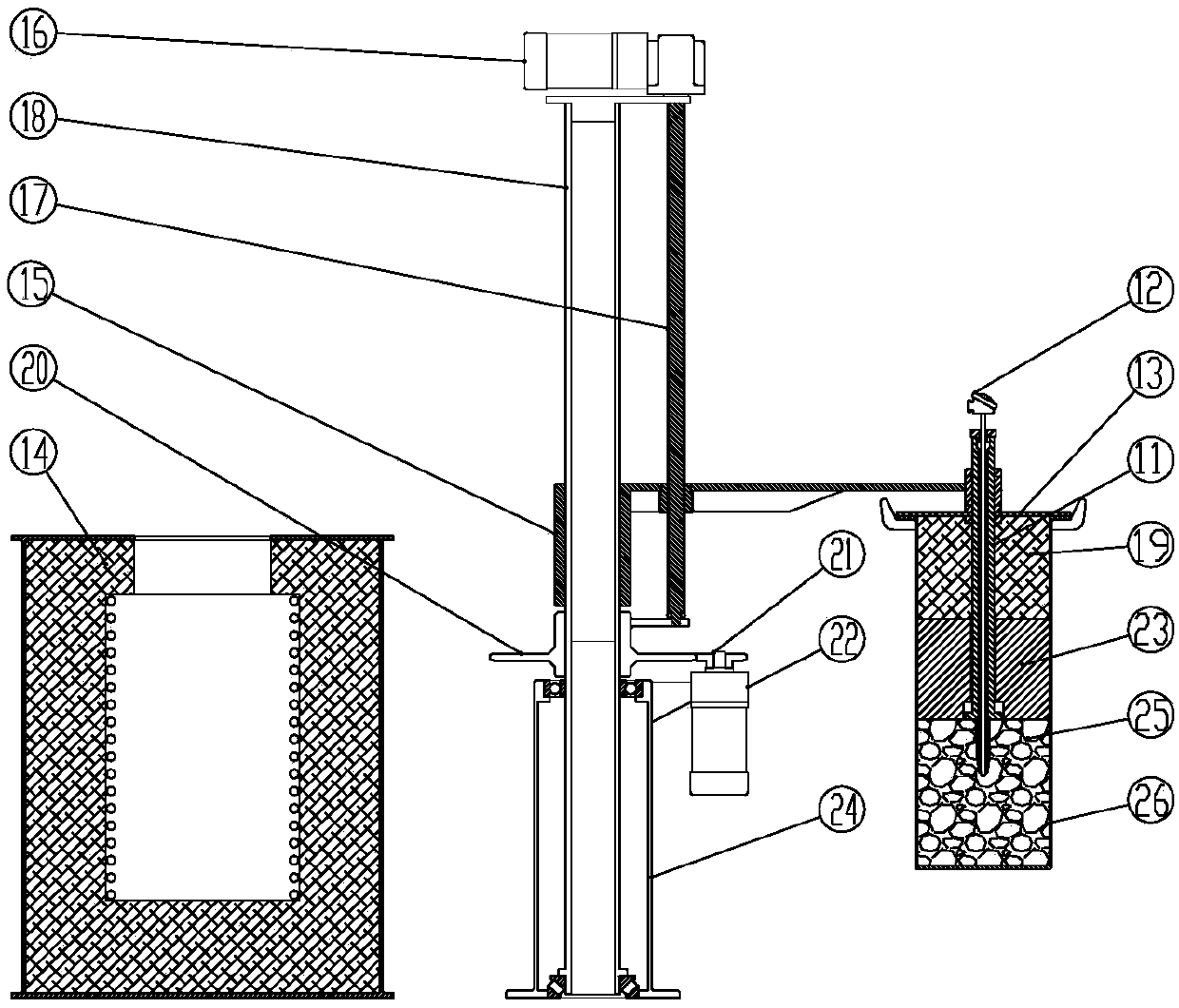

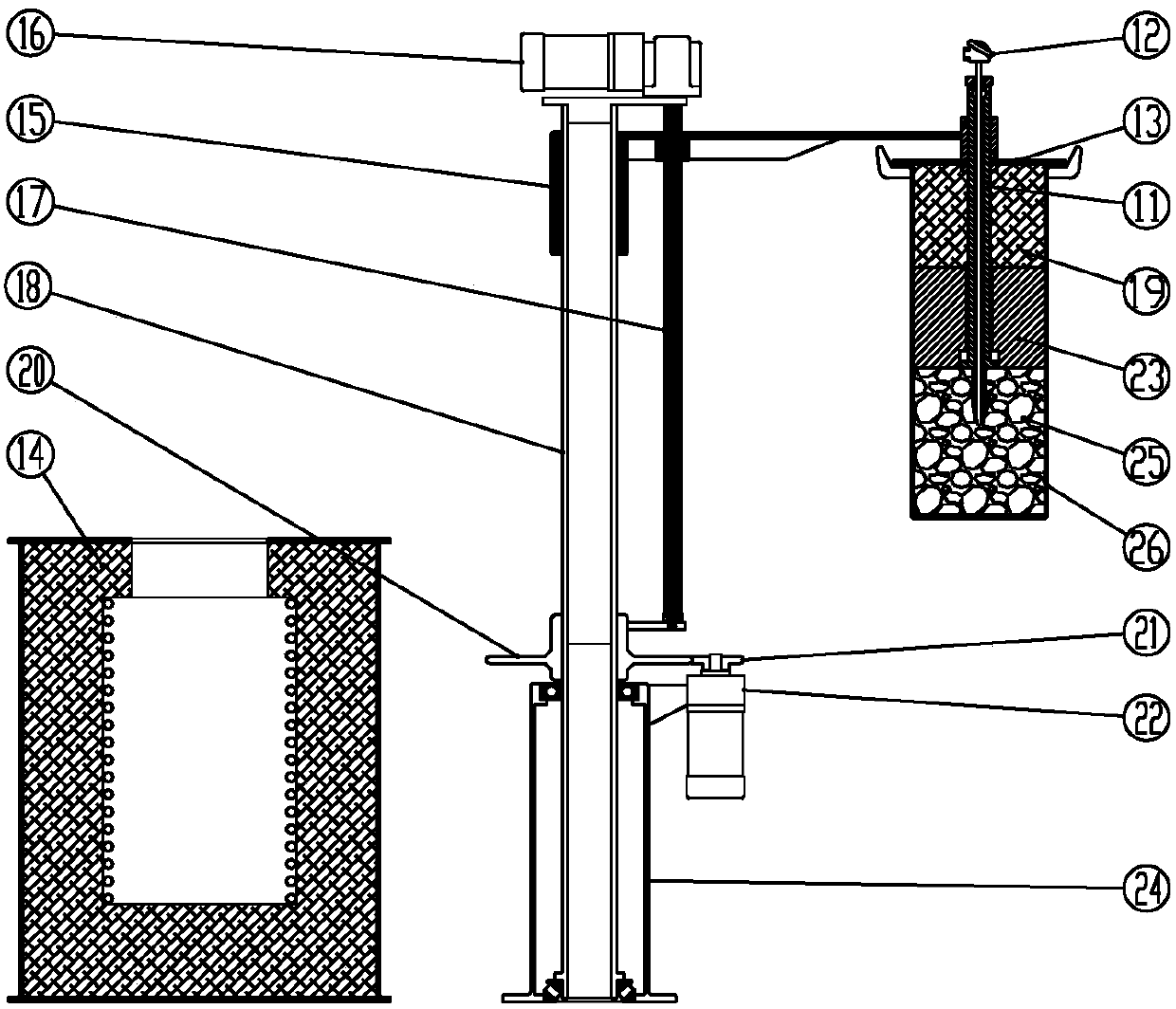

[0058] See figure 1 , is a structural schematic diagram of an environment-friendly load test coke oven according to the present invention. The present invention is an environment-friendly load test coke oven, which includes a test coke oven, a coking by-product condensation recovery device and a coke pot assembly moving device. The test coke oven consists of a heating furnace body 14 and a coke pot assembly placed in the heating furnace body 14 Composition, the coke tank assembly includes the coke tank 26, the coke tank upper cover 13, the load weight 23, the fiber insulation cover 19 and the connecting sheath tube 11, and the connection protection sleeve tube 11 connects the load weight 23, the fiber insulation cover 19 and the coke tank The upper cover 13 is connected in series and placed in the coke tank 26 as a whole, and the coal blending sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com