A kind of double-deck piling equipment

A double-layer, equipment technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of inconvenient construction, waste of resources, hidden danger of superstructure, etc., and achieve simple structure, convenient operation, and firm pile down. effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

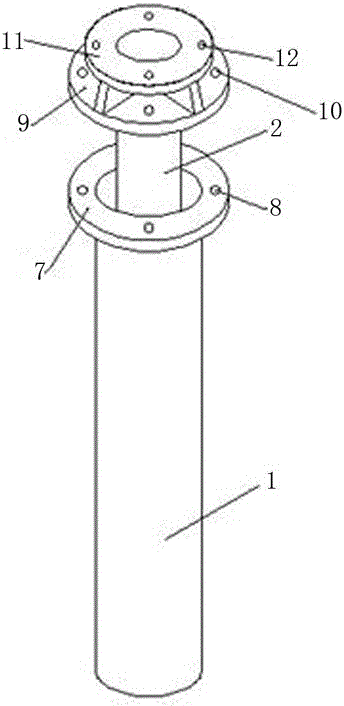

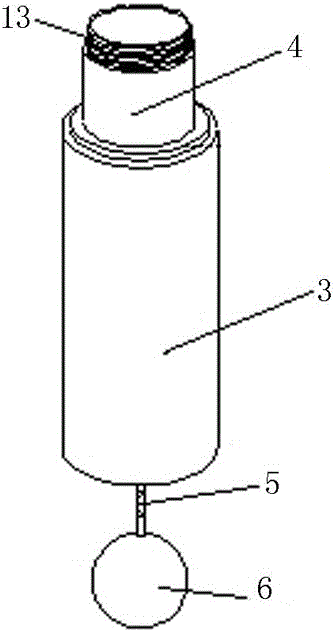

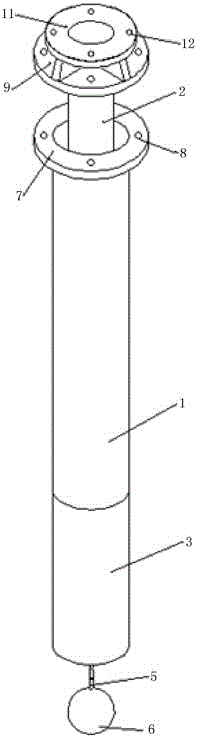

[0014] Such as figure 1 , 2 As shown in , 3, a kind of double-deck piling equipment, comprises pile outer tube 1, the inside of described pile outer tube 1 is set with pile inner tube 2, is connected with pile head 3 below pile outer tube 1, pile head 3 is provided with an inner pipe connector 4 connected to the pile inner tube 2, the pile head 3 is a hollow structure, the inner pipe connector 4 communicates with the pile head 3, and the iron chain is passed under the pile head 4. 5. The active connection has a plug 6.

[0015] The pile body tube 1 is set on the outside of the pile body tube 2, the top of the pile body tube 1 is provided with a first connection plate 7, the first connection plate 7 is provided with a first connection hole 8, the top of the pile body tube 2 A second connection plate 9 is provided, and a second connection hole 10 matched with the first connection hole 8 is opened on the second connection plate 9, and a support connection pipe connection plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com