Formwork pouring device for building construction

A technology of building construction and formwork, which is applied in the direction of construction, building structure, and on-site preparation of building components, etc. It can solve the problems of wasting preparation time for construction personnel and installation and disassembly time, inconvenient installation and disassembly, and affecting construction efficiency. , to achieve the effect of solving easy dumping, improving stability and flexible adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

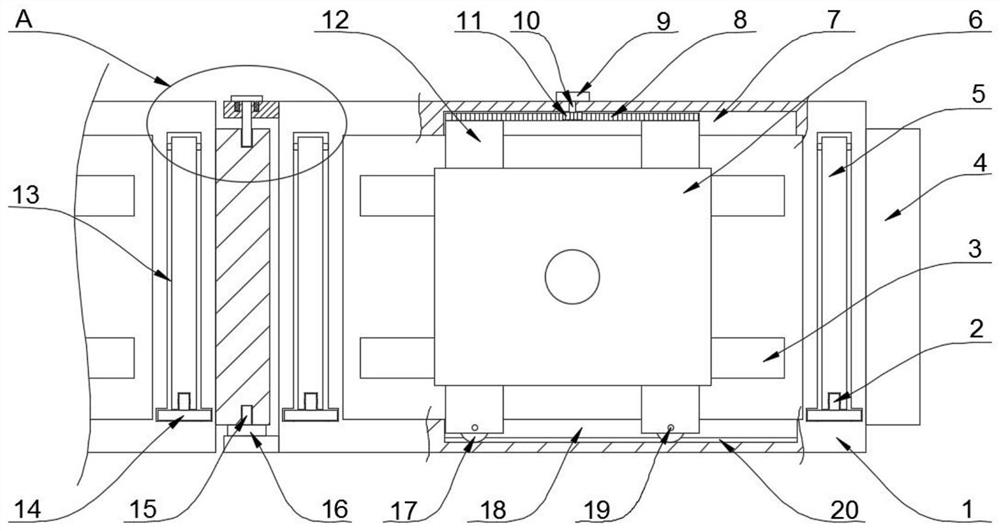

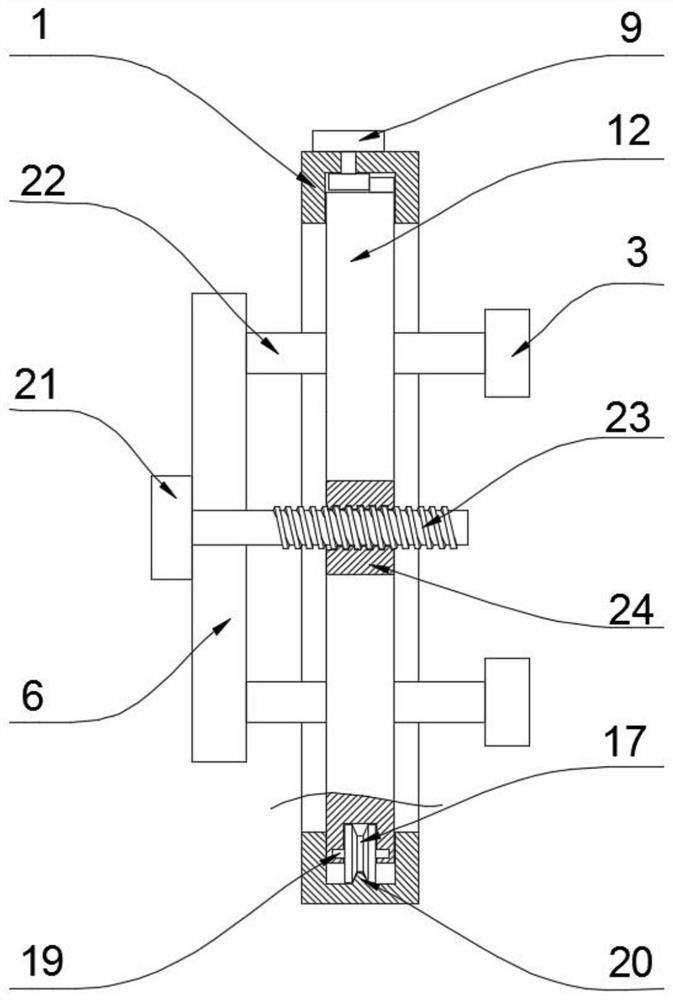

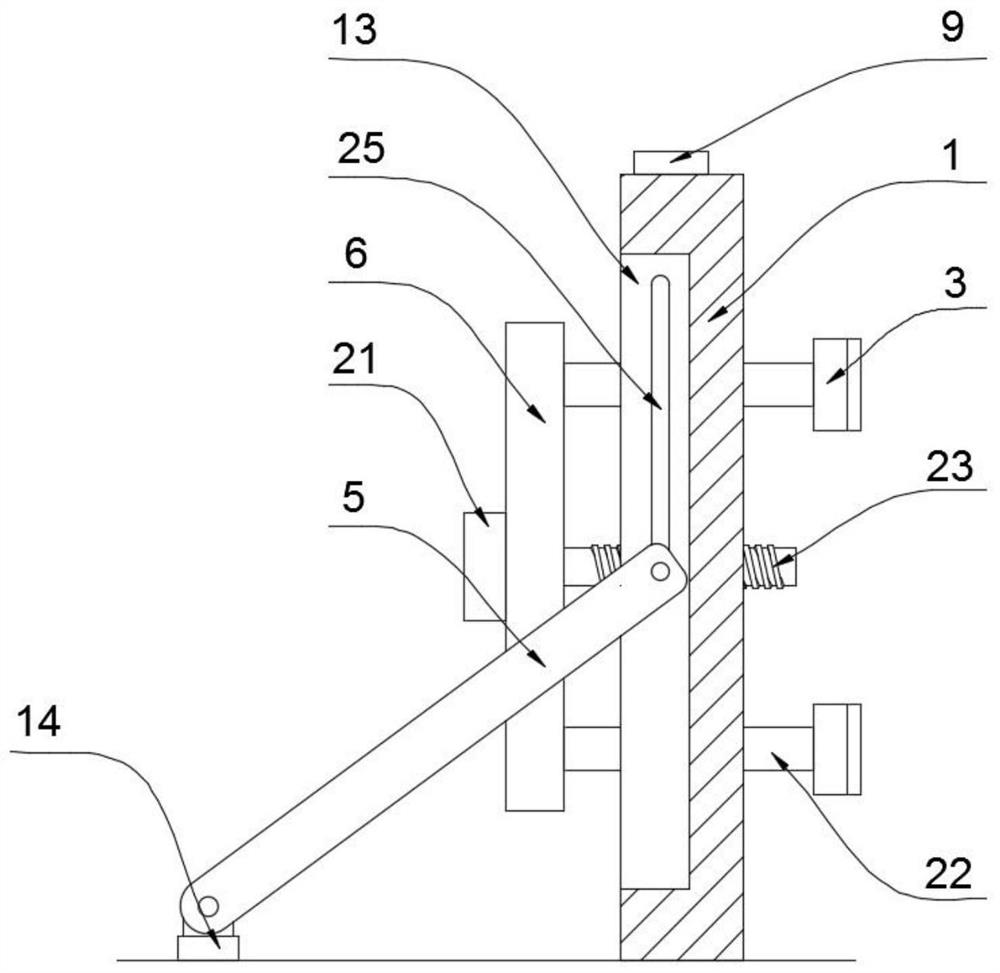

[0025] refer to Figure 1-5 , a formwork pouring device for building construction, comprising a support frame 1, the support frame 1 is a square metal frame, an upper groove 7 is provided above the support frame 1, a lower groove 18 is provided below the support frame 1, and an upper groove 7 Two vertical rods 12 are jointly slidably connected with the lower groove 18, and the two vertical rods 12 are jointly welded and fixed with a connecting block 24. The extrusion rod 3 is fixed, and the four cross bars 22 are welded together to fix the fixed plate 6. The geometric center of the fixed plate 6 is rotatably connected to the threaded rod 23. One end of the threaded rod 23 is coaxially welded and fixed with a stopper 21, and the connecting block 24 is provided with a There are threads matching the threaded rod 23 which engages with the connecting block 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com