Shape-memory alloy stranded wire self-centering frictional buckling-restrained brace

An anti-buckling bracing, memory alloy technology, applied in earthquake-proof, building components and other directions, can solve the problems of insufficient energy dissipation capacity, increase maintenance and reconstruction costs after earthquakes, etc., and achieve sufficient energy dissipation effect, good self-reset function, high The effect of carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

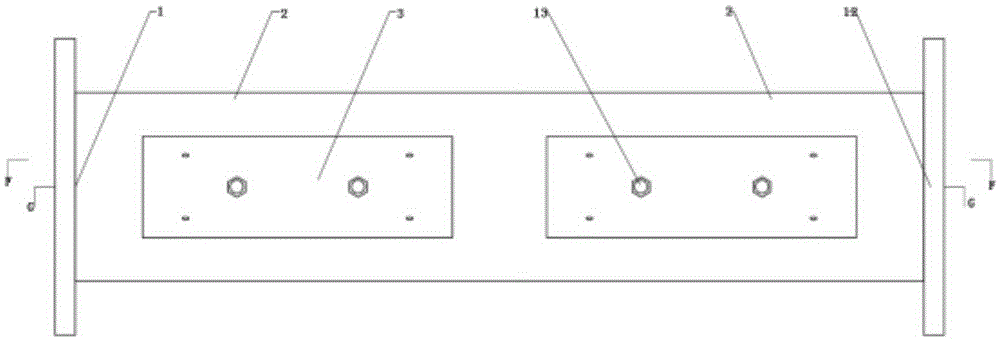

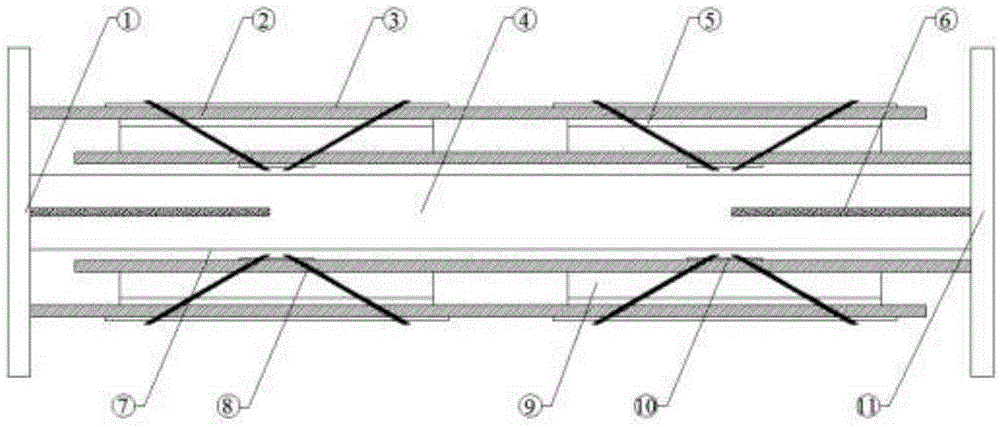

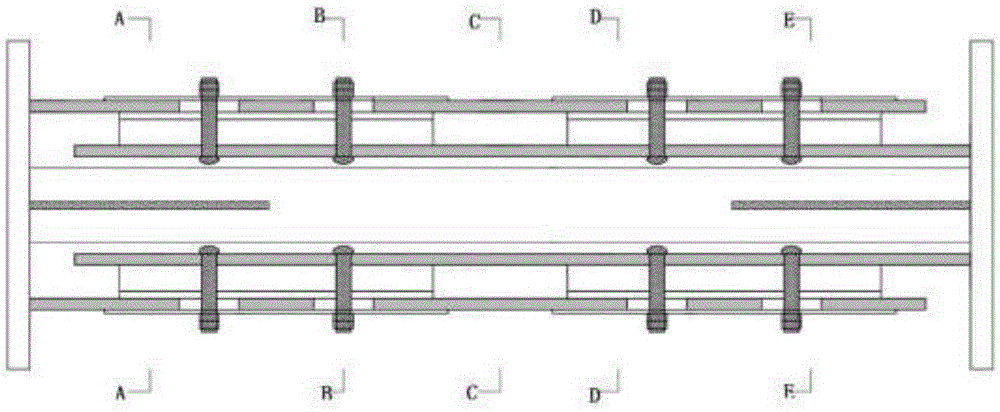

[0032] combine Figure 1-6 Embodiments of the self-resetting friction anti-buckling brace will be described.

[0033]The anti-buckling part: the in-line steel plate is made of Q235 steel with low yield point, and two stiffeners are welded at both ends of the in-line steel plate to realize the smooth transition of the inner core section so as to avoid the influence of stress concentration. The ends are welded to the left and right end plates respectively. The inner casing acts as a peripheral restraining steel pipe and is set outside the inline steel plate, and the inline steel plate is arranged obliquely and diagonally in the inner casing, and there is a certain gap between the inner steel casing and the inner core of the inline steel plate, so as to ensure The inner core can freely deform and dissipate energy, and at the same time, it can form an anti-buckling mechanism to prevent local buckling of the in-line steel plate.

[0034] The friction part: the inner steel sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com