Method for detecting integrity of weld through ultrasonic guided wave array

An ultrasonic guided wave and integrity technology, which is applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, etc., can solve the problems of incomplete detection, inability to identify and reasonably evaluate the integrity of welds, etc., and achieve the effect of high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in combination with specific embodiments.

[0021] A method for detecting weld integrity with an ultrasonic guided wave array proposed by the present invention comprises the following steps:

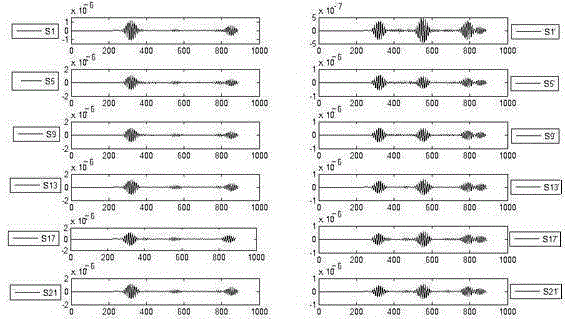

[0022] a. Excite L(0,2) symmetric guided waves in pipeline welding, and arrange sensor arrays on both sides of the weld. The sensor array method is to arrange 16 sensors evenly on both sides of the weld, a total of 32 sensors, respectively marked as S 1q ,S 2q ,….S 16q , indicating the sensor at the front end of the weld; S 1h ,S 2h ,….S 16h , indicating the sensor at the back end of the weld.

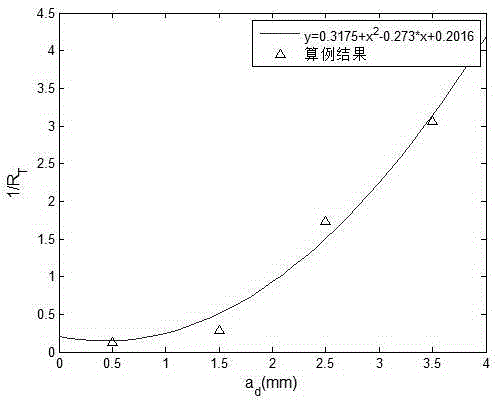

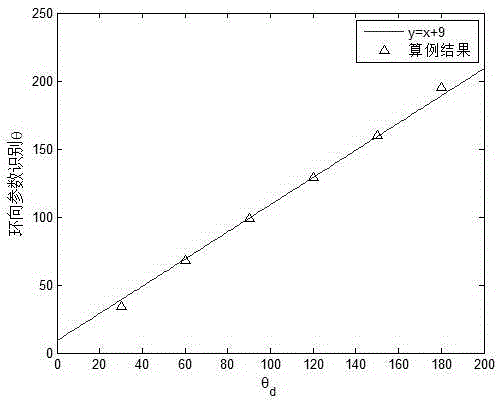

[0023] Such as image 3 As shown, the peak value of the guided wave signal recorded by the No. 1 sensor after the weld is divided by the peak value of the guided wave signal recorded by the No. 1 sensor before the weld to obtain the transmission coefficient, and by analogy, the circumferential distribution of 16 transmission coef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com