Weathervane zero position correction device

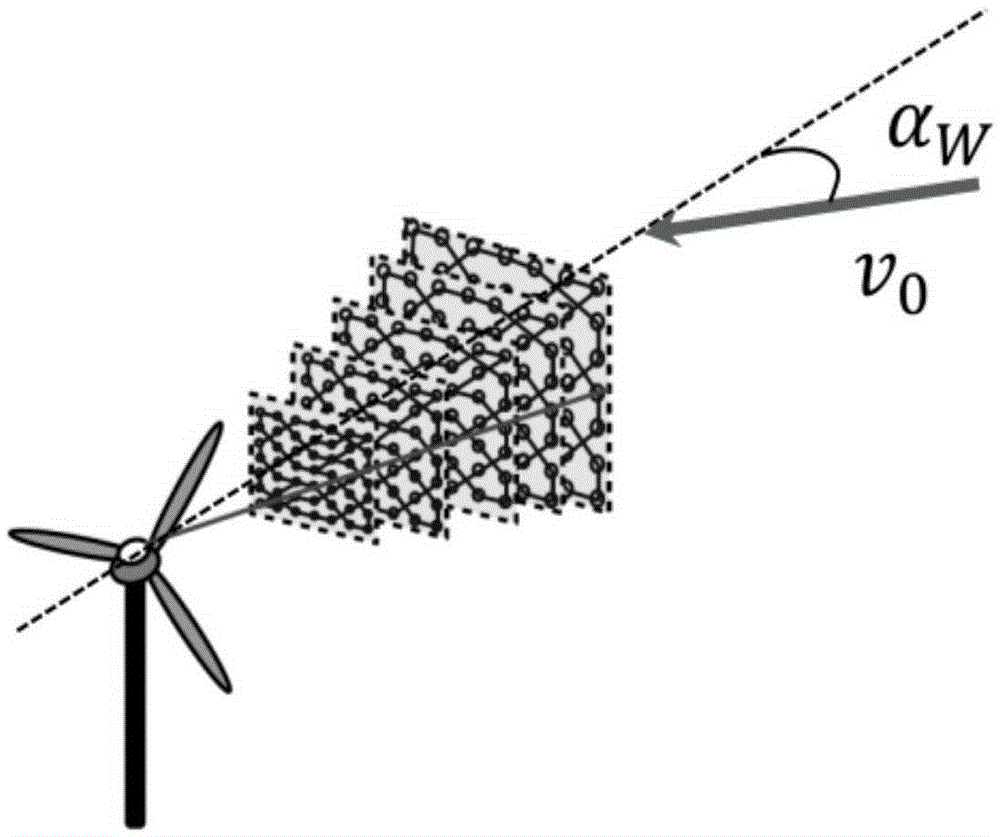

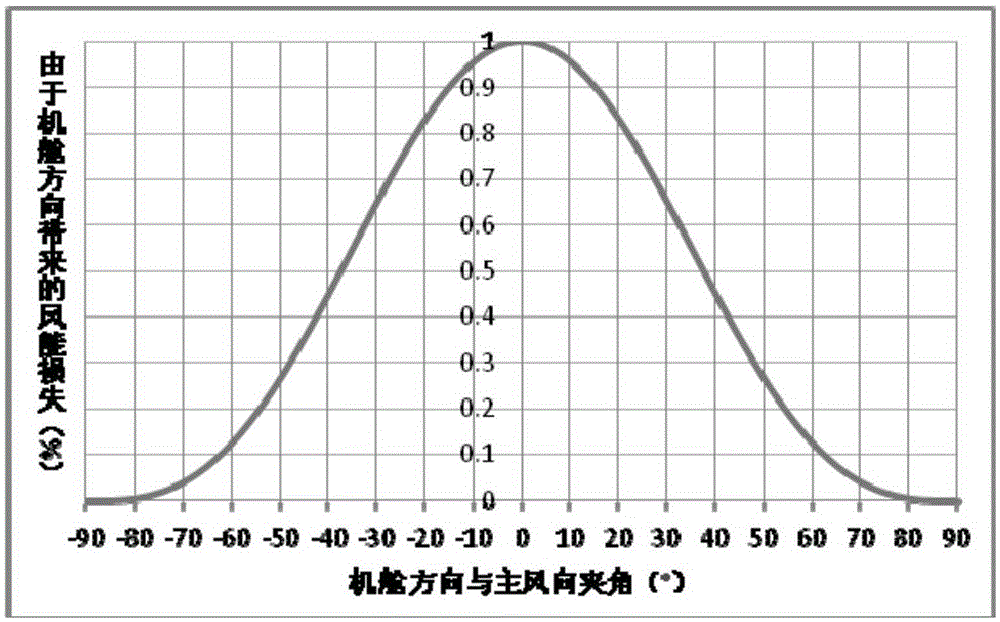

A zero-position correction and weather vane technology, which is used in measurement devices, testing/calibration of speed/acceleration/impact measurement equipment, instruments, etc., can solve the problems of large zero-to-zero error, increased measurement error, and difficult confirmation. Achieve the effect of promoting lift, reducing measurement error, and reducing the degree of yaw to wind inaccuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

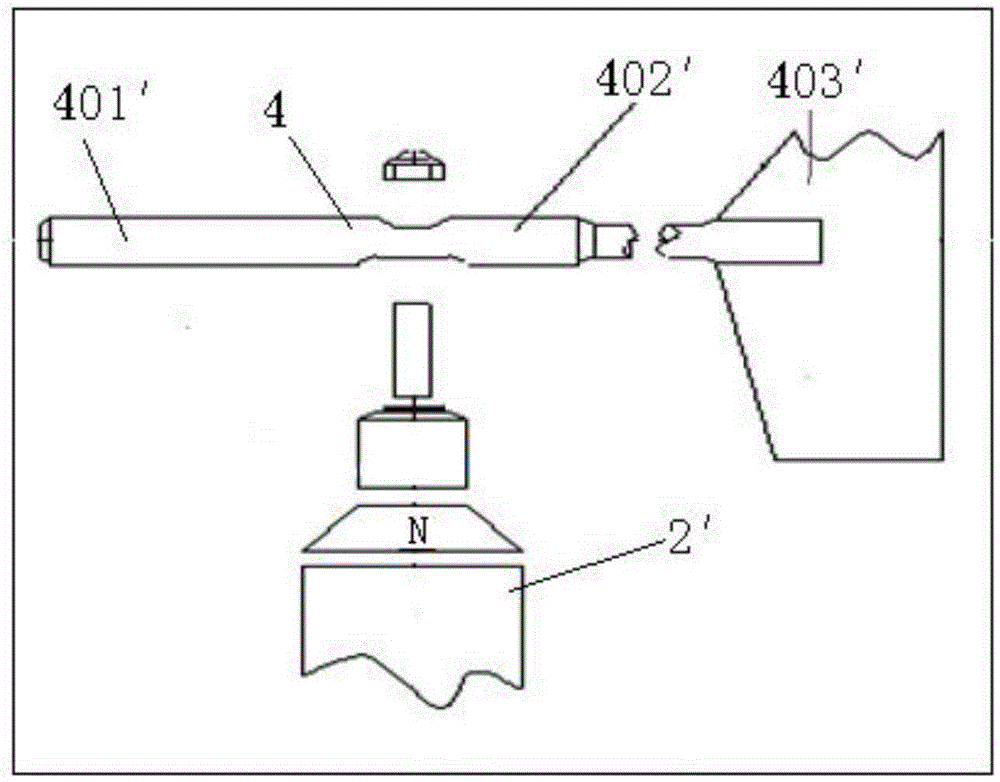

[0052] In order to achieve the purpose of the present invention, as Figures 4 to 6 As shown, the wind vane zero correction device of the present invention includes a wind vane angle correction part 1, a main shaft angle correction part 2 and an angle adjustment part, and the wind vane angle correction part 1 is installed outside the test device 3, and is connected with the wind vane 10 on the test device 3 Connected, the wind vane angle correction part 1 is used to adjust the angle of the wind vane 10; the main shaft angle correction part 2 is installed on the main shaft 5 in the test device 1, and the main shaft angle correction part 2 is used to measure the angle of the main shaft 5; the angle adjustment parts are respectively connected with the wind vane 1. The main shaft angle correction parts 1 and 2 are connected, and the angle of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com