A FEM-Based Analysis Method for Aircraft Door Sealing Load

A finite element and aircraft technology, applied in the direction of instruments, calculations, electrical digital data processing, etc., can solve problems such as torque calculations, and achieve the effect of improving solution efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

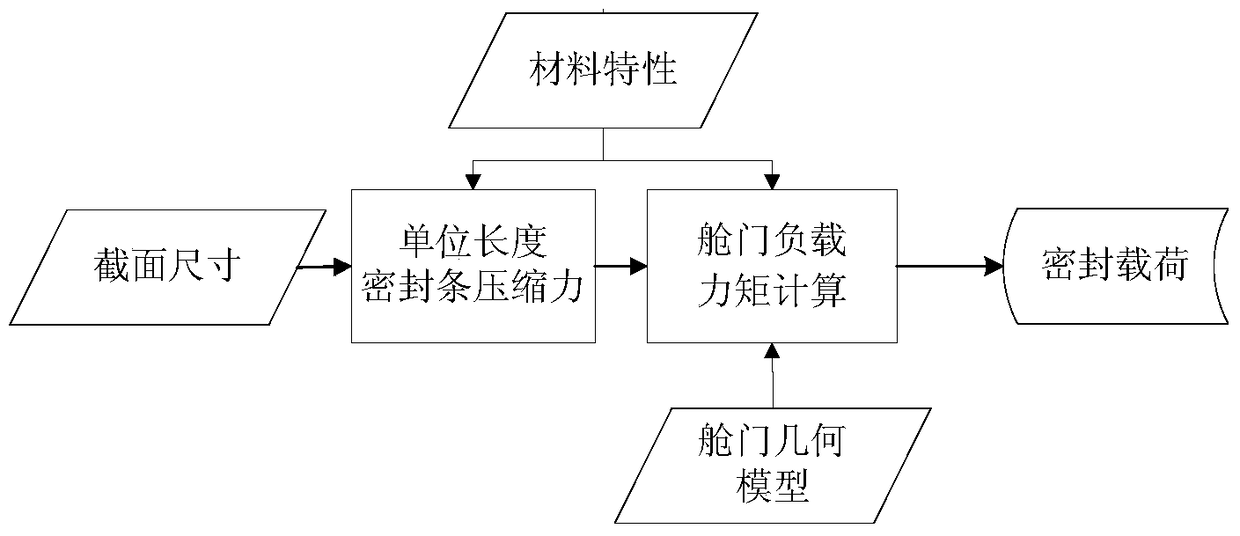

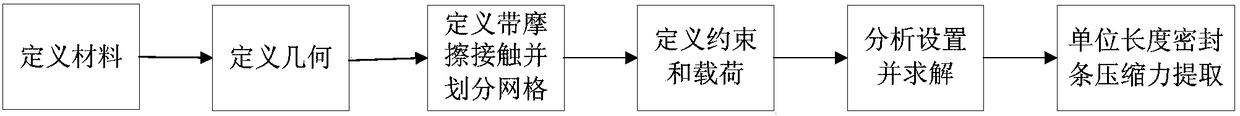

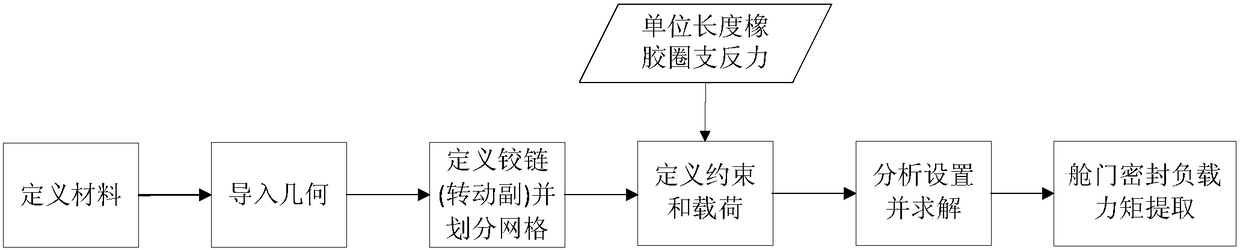

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The material properties of each part of a hatch are shown in Table 1. The inner diameter of the section of the sealing strip is 7mm, the outer diameter is 10mm, and the compression amount is 5mm. Using the above-mentioned relay solution method for seal load design, the deformation and stress of the seal strip are obtained. The compression force of the seal strip is 0.8274N / mm; the door seal load moment is 151.6N·m.

[0055] Table 1

[0056]

[0057] The method of the invention has been applied to model design, and the air vehicle door sealing load calculated by the method provides a design basis for the aircraft door opening and closing mechanism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com