Automatic Nail Splitter

An automatic nail splitting machine and nail feeding technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve problems such as damage, automation equipment damage, machine vibration and slipping, etc., to avoid safety hazards, speed up falling speed, and reduce frictional resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

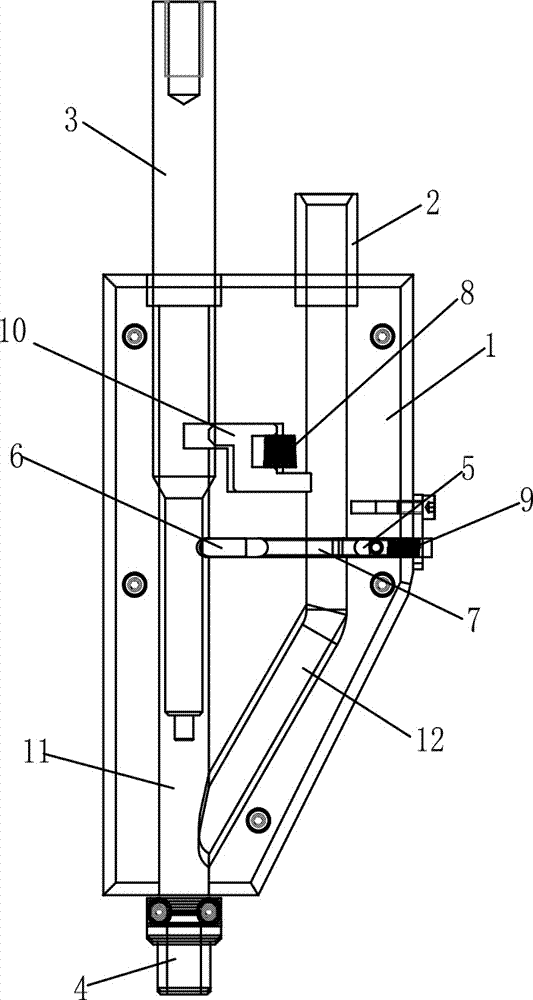

[0047] like figure 1 As shown, the present invention includes a base 1, a nail feeding tube 2, a nail dividing rod 3, a material discharging guiding tube 4, a material distributing tongue 5, a material distributing valve 6, a material distributing rod 7, return springs 8, 9, Active card material valve 10.

[0048] The nail feeding tube 2 is inserted into the opening of the nail feeding groove 12 in the base 1, and is fixedly connected with the base 1; 3 is parallel to the nail feeding tube 2; the nail feeding groove 12 includes two sections, the first section is parallel to the insertion rod groove 11, and the second section is used to connect the insertion rod groove 11 and the first section of the nail feeding groove 12; the movable jam valve 10 is installed in the base 1, and is located between the first section of the nail feeding groove 12 and the insertion rod groove 11. The movable jamming valve 10 is connected and matched with the return spring 8 fixed in the base 1; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com