A device for directional stretching and synergistic softening of winding yarn hairiness

A yarn and heating device technology, which is applied in the field of textile processing, can solve the problems of increased fabric appearance defects, reduced hairiness, and reduced hairiness on the surface of the yarn, so as to be easy to popularize and use in large areas, improve tightness and fastness, and avoid fiber Gathering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

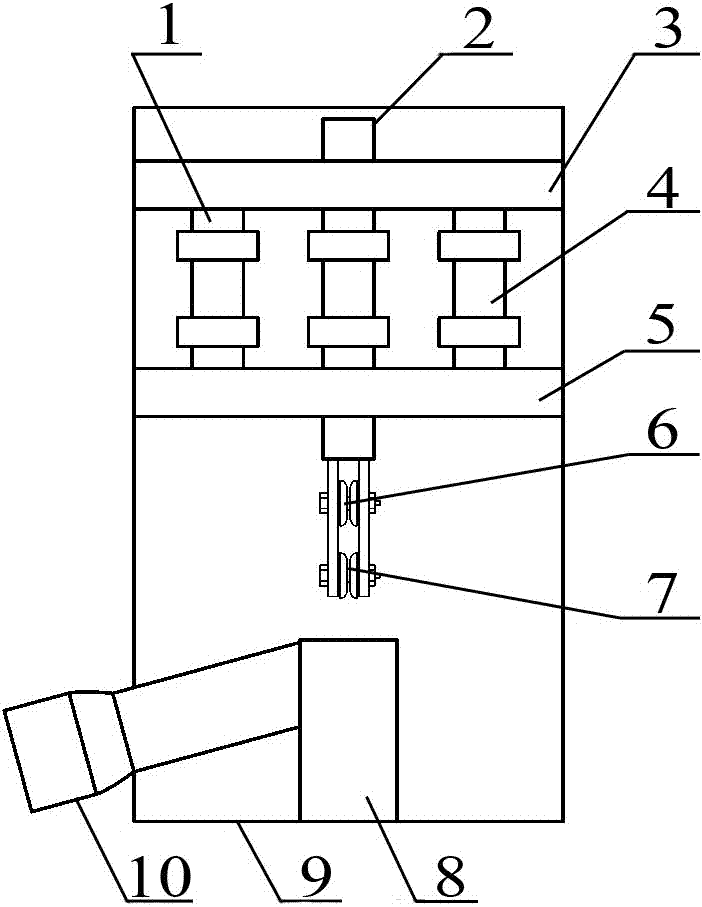

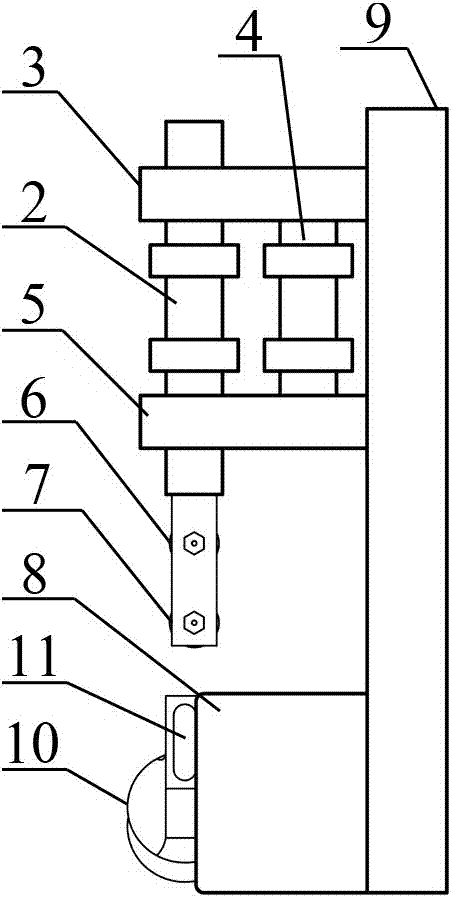

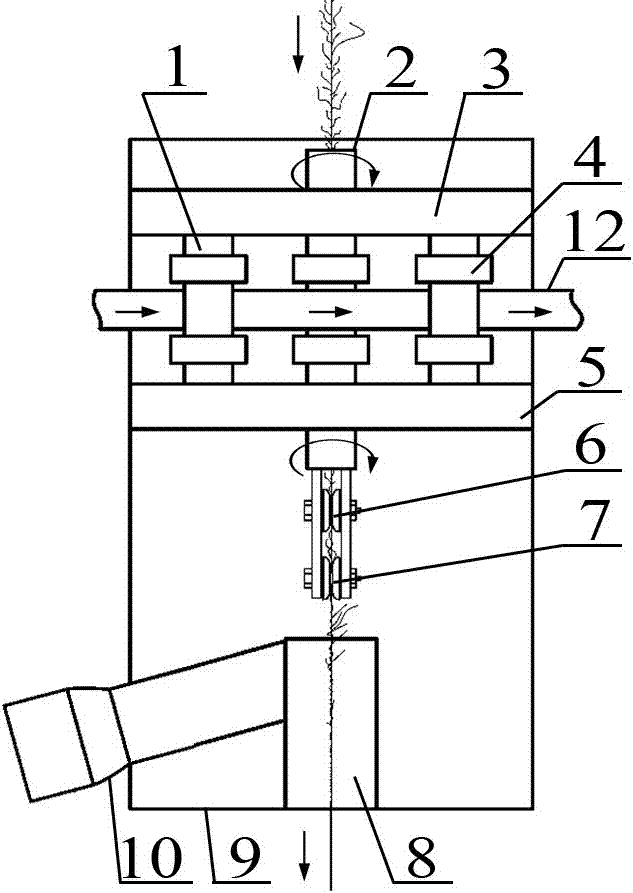

[0021] Example 1: Improvement of yarn finish during warping

[0022] On the warping machine, the screw and hook fixing device are used to fix the device for directional stretching and softening the hairiness of the winding yarn through the base 9 on a row of yarn guide rods at the yarn output end of the warping machine creel, and the directional stretching The wrapping hairiness device is located between the yarn guide rod and the telescopic buckle, and the pre-loaded yarn guide hook is set between the directional stretch wrapping hairiness device and the wire guide on the yarn guide rod, and the directional stretch wrapping hairiness device and the telescopic Yarn guide hooks are arranged between the buckles, and the speed-regulating motor is installed on the main body support rod of the creel, and the energy obtained by an external power source drives the movement of the transmission belt 12, and the transmission belt 12 is in a one-up, one-up, and down-style, respectively wi...

Embodiment 2

[0023] Example 2: Improvement of spun yarn finish during warp knitting with hairy yarns

[0024]Compared with weft knitting, warp knitting speed is fast and output is high; warp knitting speed is high, if the surface of the yarn is hairy, it is easy to damage the knitting needles, so at present, warp knitting is mainly produced with smooth filaments. Adopting the present invention can solve the hairiness problem of short fiber yarn, so that the multi-hairy short fiber yarn can be used for warp knitting. The device for wrapping yarn hairiness is fixedly installed on the yarn guide frame of the let-off structure of the warp knitting machine through the base 9, and the directional stretch type wrapping hairiness device is located between the positive let-off structure and the wire feeding hook of the loop forming mechanism. Yarn-feeding guide hooks are set between the type wrapping hairiness device and the polar let-off structure, yarn-out guide hooks are set between the directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com