Method for testing pulling force of cotton swab fiber head

A test method and fiber head technology, applied in the detection field, can solve the problem of no sample detection of fiber head pull-out force, etc., to achieve the effect of ensuring quality and increasing winding tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

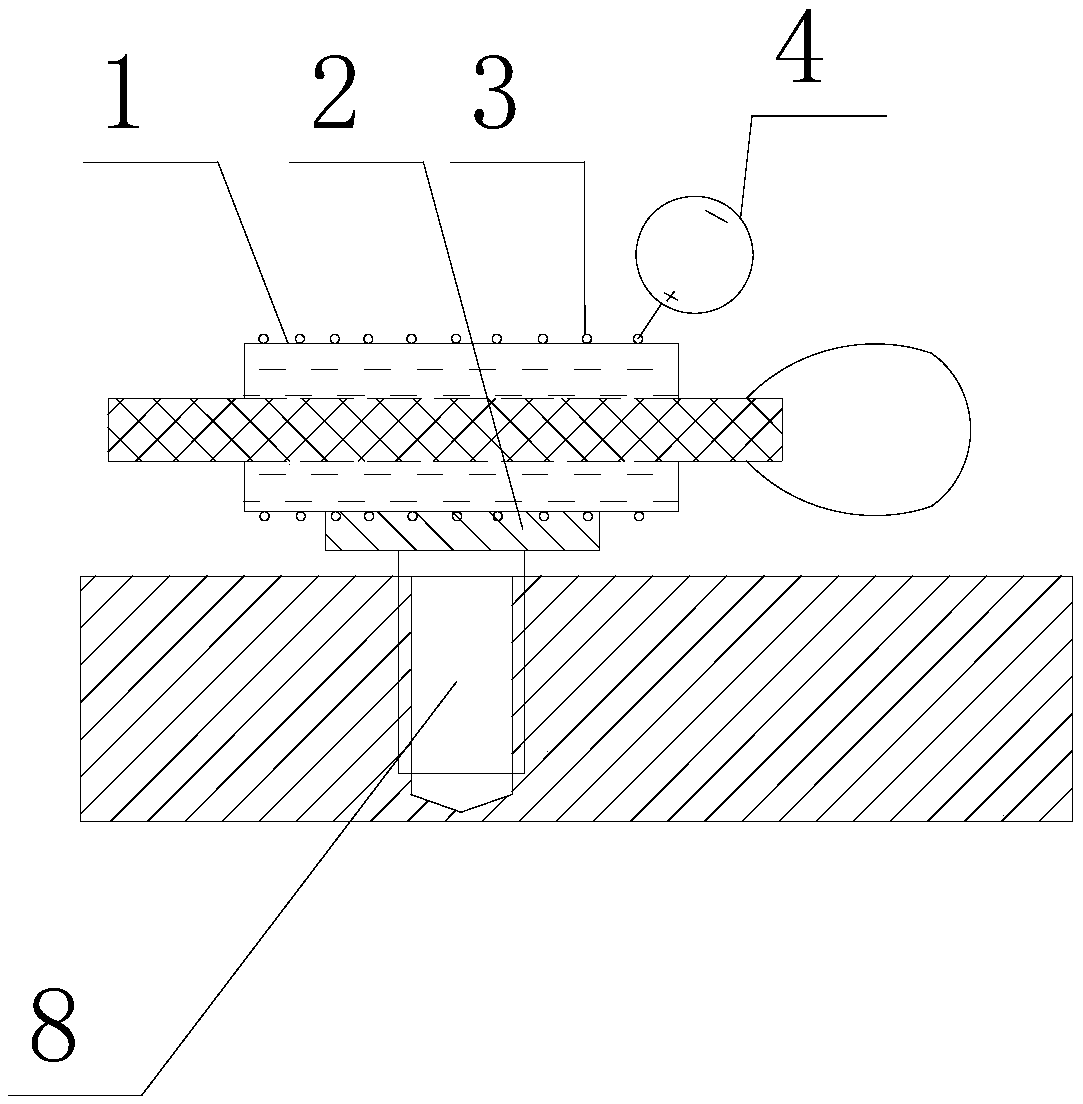

[0021] Embodiment 1, as attached figure 1 Shown:

[0022] The cotton swab fiber head pull-out force test method includes the following steps: the first step is to select 20 cotton swabs to be tested in the same batch to be tested; the second step is to clamp all the cotton swabs to be tested on the same level with a synchronous fixture. The fixture includes The clamping seat 5 and the clamping seat 5 are fixed with a plurality of clamping parts of the same horizontal line. The clamping parts include a support plate 6 and a support hole 7. The support plate 6 bolts 8 are connected to the clamping seat 5, and the support plate 6 and the clamping seat 5 are provided with a gap for the cotton swab to pass through, the support hole 7 runs through the support plate 6 longitudinally, and the aperture of the support hole 7 is larger than the diameter of the cotton swab to be tested by 0.2mm; When the cotton swab comes out of the fiber head to the cotton swab to be tested, record the ...

Embodiment 2

[0042] Different from Example 1, after the first step selects a plurality of cotton swabs to be tested, the cotton swab of the cotton swab to be tested is shortened from the end away from the fiber head, and the length of the shortened cotton swab is the original length of the cotton swab. one-half of. In this way, the cotton swab can be shortened to reduce the increase of the contact area between the cotton swab and the support hole due to the curvature of the cotton swab itself, resulting in an increase in friction. At the same time, it can be ensured as much as possible that the cotton swab and the tension clamping head are on the same vertical line to ensure the effectiveness of the tension.

Embodiment 3

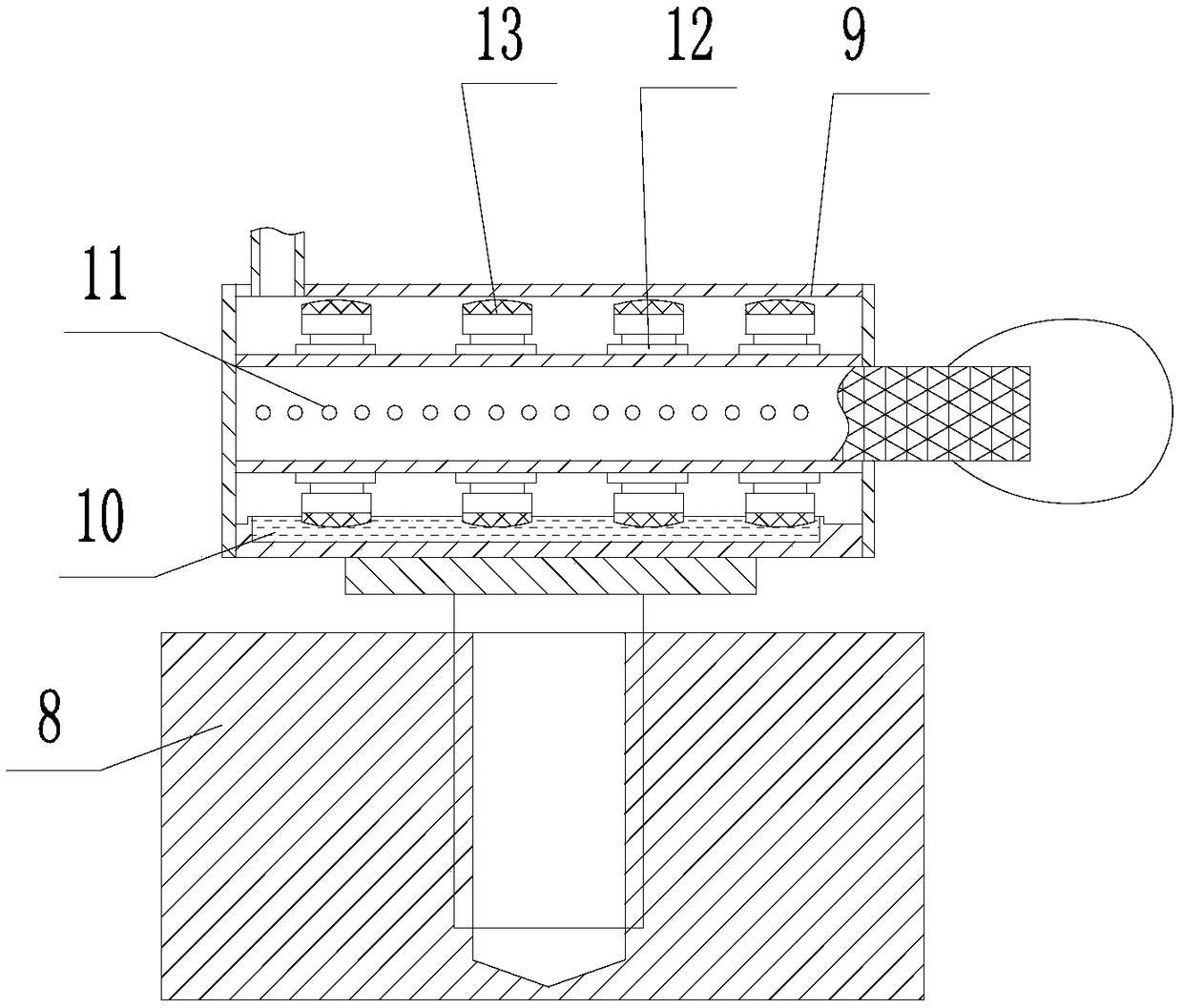

[0043] Embodiment 3, as attached figure 2 Shown:

[0044] The difference from Example 1 is that in the first step, the ratio of the number of cotton swabs to be tested to the total number of cotton swabs in the same batch is selected to be 1:300. Pulling force moves away from the fiber head at a speed of 500mm / min until the fiber head comes out of the cotton swab. The clamping seat 5 is provided with a plurality of annular chambers 1 with built-in magnetorheological fluid. The annular chamber 1 is an elastic structure and its inner hole diameter is 0.3 mm larger than the diameter of the cotton swab to be tested. The outer surface of the annular chamber 1 is A coil 3 is wound, and a power supply 4 is connected in series with the coil 3 .

[0045] In the specific implementation process, when selecting the cotton swabs to be tested, the total number of cotton swabs in the same batch is selected according to a certain ratio. In this embodiment, the extraction is performed accor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com