Resistance balance valve

A technology of resistance balance and valve plate, which is applied in the field of resistance balance valves, can solve the problems of material extraction, pipeline wear, and small air volume of vacuum hoods, etc., and achieve good concentricity, reduce wear, and intuitive and convenient adjustments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

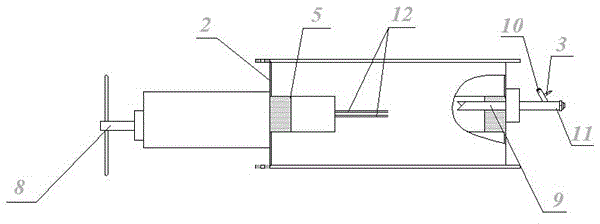

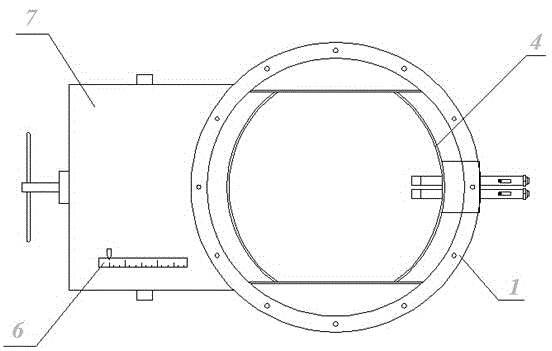

[0020] Such as figure 1 As shown, the present invention includes a pipe body 2, an anti-clogging measuring device, a fixed arc valve plate 4, a movable arc valve plate 5, a movable valve box 7, and an adjusting handle 8. Flanges 1 are provided at both ends of the pipe body 2 , the anti-clogging measuring device includes a soot removal device 9, a settling chamber communicated with the soot removal device 9, and an air induction pipe 3 communicated with the settling chamber, and the ash removal device 9 and the settling chamber are respectively located in the inside of the pipe body 2 and the outside; the left end of the movable arc valve plate 5 is located in the movable valve box 7, and the right end is the working part located in the pipe body 2, and its two sides are movably connected to the bracket 12 provided by the pipe body 2, and the left end is passed through the ball The leading screw is connected with the adjustment handle 8, and grooves are provided on both sides o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com