Machine feeding control method and implementing device thereof

A feed control and machine tool technology, applied in electrical program control, program control in sequence/logic controller, metal processing, etc., can solve complex data setting operations, limited feed speed, no error compensation, etc. problems, to achieve the effect of speeding up the feed movement, avoiding pulse interference, and avoiding lost steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

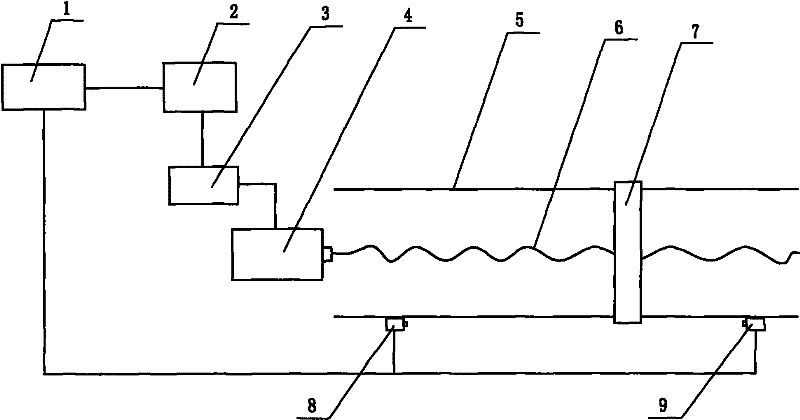

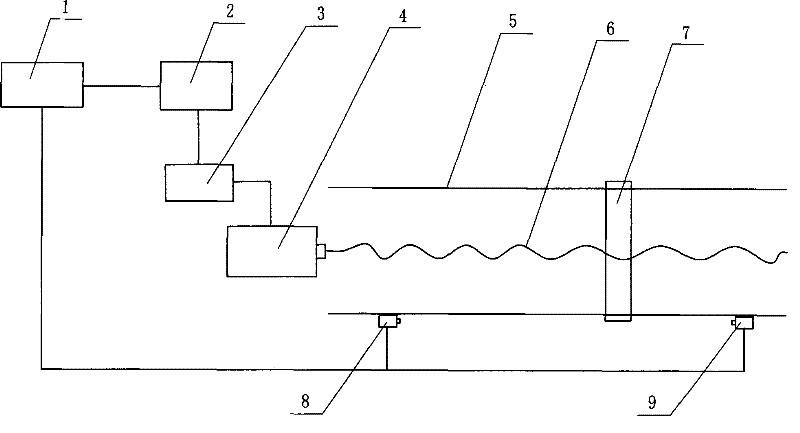

[0008] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0009] The invention adopts the feedback indirect driving control method, controls the drive of the stepper motor through the output pulse signal of the pulse generator, controls the start and stop of the pulse generator through the PLC, and feedbacks the signal after the stroke switch is positioned and sensed to feed the position of the slide plate. Control the PLC to issue commands. First, the PLC sends a start command to the pulse generator, and the pulse generator starts to send pulse signals to the stepper motor driver without interruption. The stepper motor drives the stepper motor to run according to the pulse signal, and the motor drives the screw to rotate. , the screw rotates to drive the slider of the screw pair to move linearly, the slider belt slides linearly with the feed slide, the feed slide moves to the second travel switch to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com