X-shaped throttling mechanism with connecting rod sliding groove

A throttling mechanism and connecting rod technology, which is applied in the field of experimental aerodynamics, can solve problems such as motor failure and direct erosion of the throttling device, and achieve the effect of controlling the throttling position and avoiding motor failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

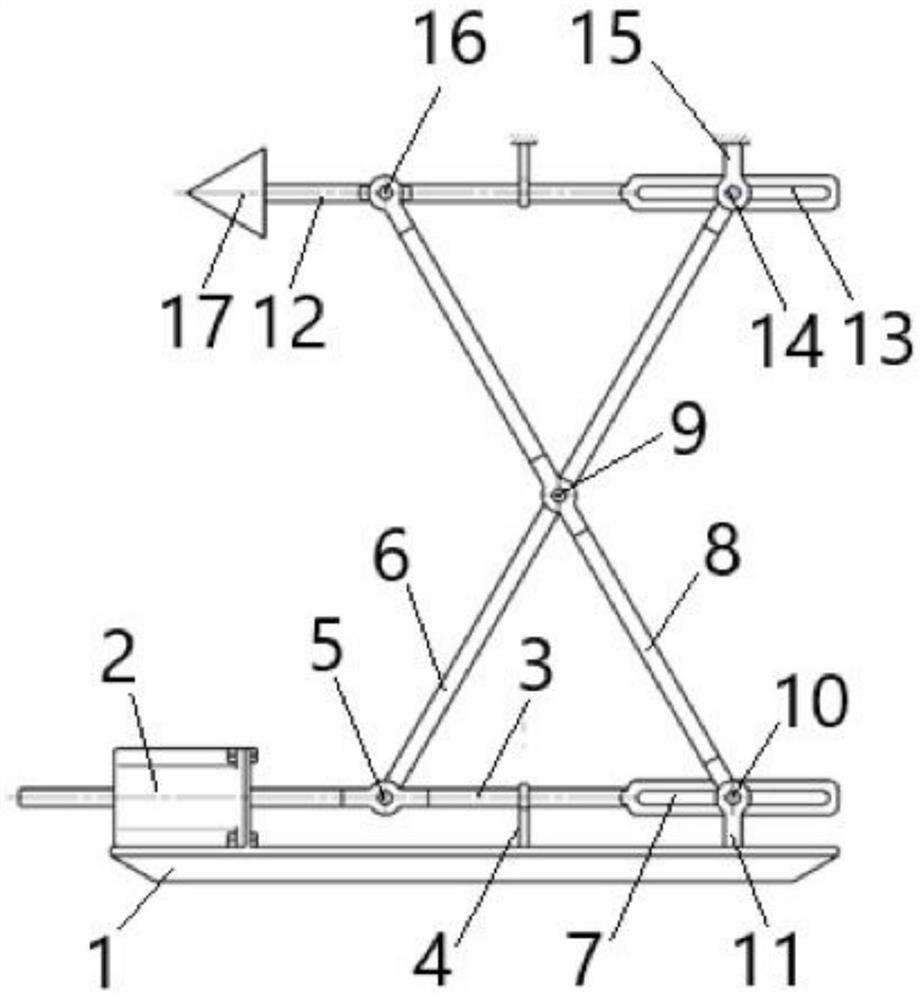

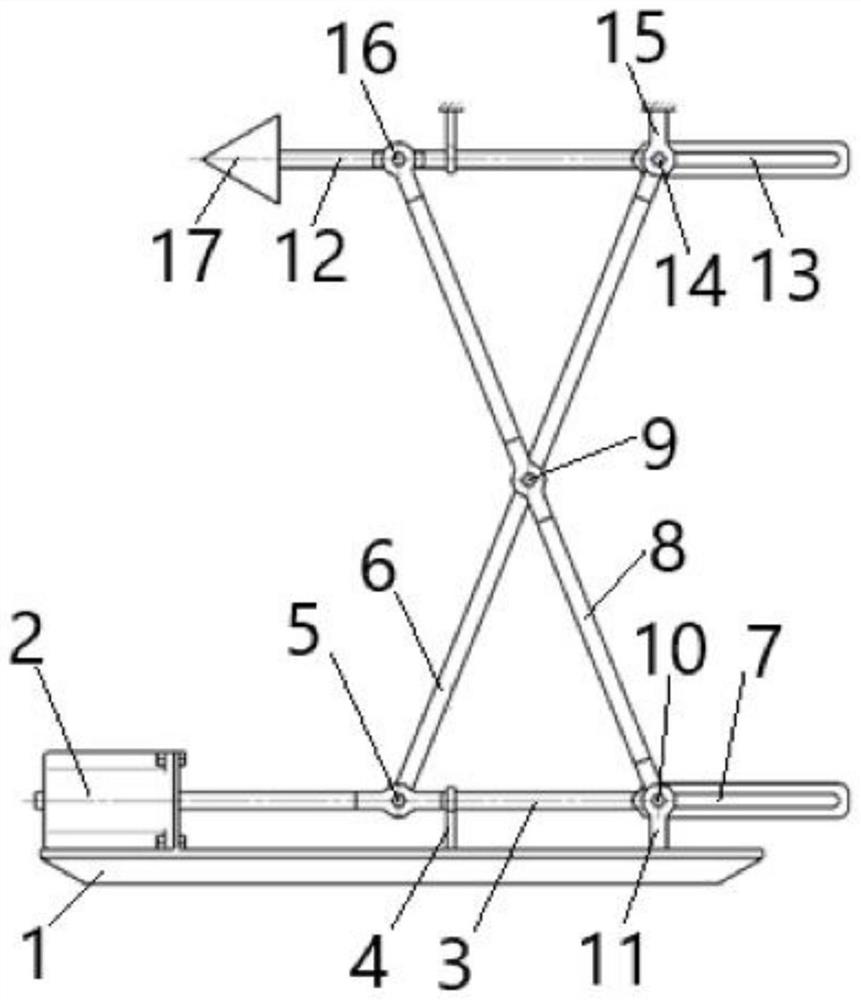

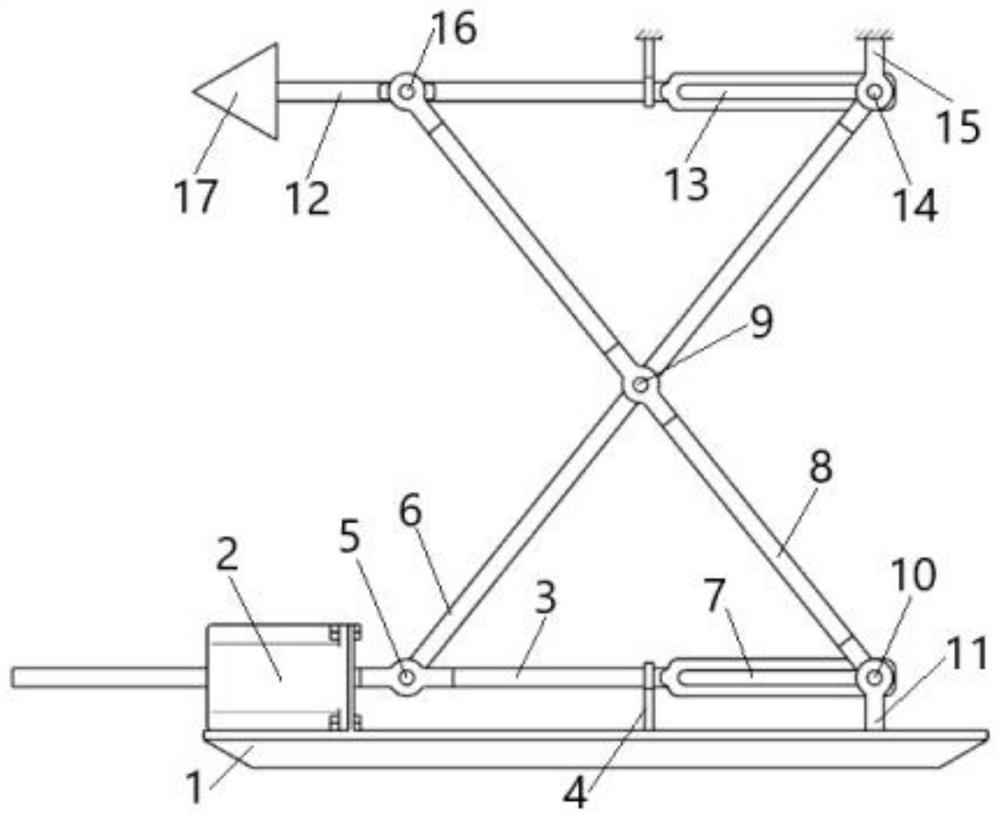

[0022] as attached figure 1 As shown, an "X" type throttling mechanism with a connecting rod chute includes a support platform 1 suspended in the air, a linear motor 2 is provided on the left side of the support platform 1, and a moving rod 3 is connected to the linear motor 2 to move The rod 3 is provided with a guide seat 4 fixed on the support platform 1 . The left side of the moving rod 3 is connected with the first connecting rod 6 through the rotation of the first movable pin shaft 5, and the right side of the moving rod 3 has a first chute 7, and the first chute 7 is slidably connected with the first connecting rod. The middle part of 6 is the second connecting rod 8 which is rotatably connected, and the second connecting rod 8 is connected with the first connecting rod 6 through the third movable pin 9. The lower end of the second connecting rod 8 is rotatably connected with a support seat 11 fixedly arranged on the support platform 1 through a second movable pin shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com