Fabric flaw detection method

A defect detection and fabric technology, which is applied in the direction of optical detection of defects/defects, can solve problems such as false detection or missed detection, insufficient use of feature space, inaccurate positioning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

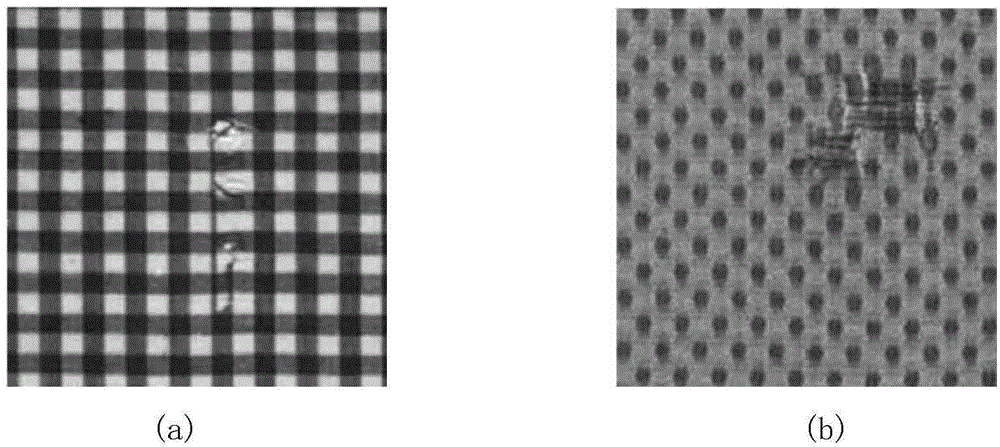

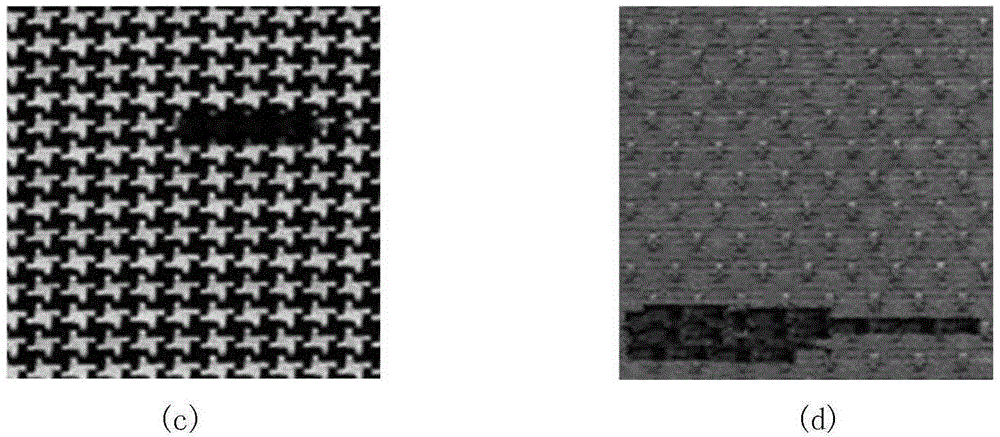

Examples

specific Embodiment approach

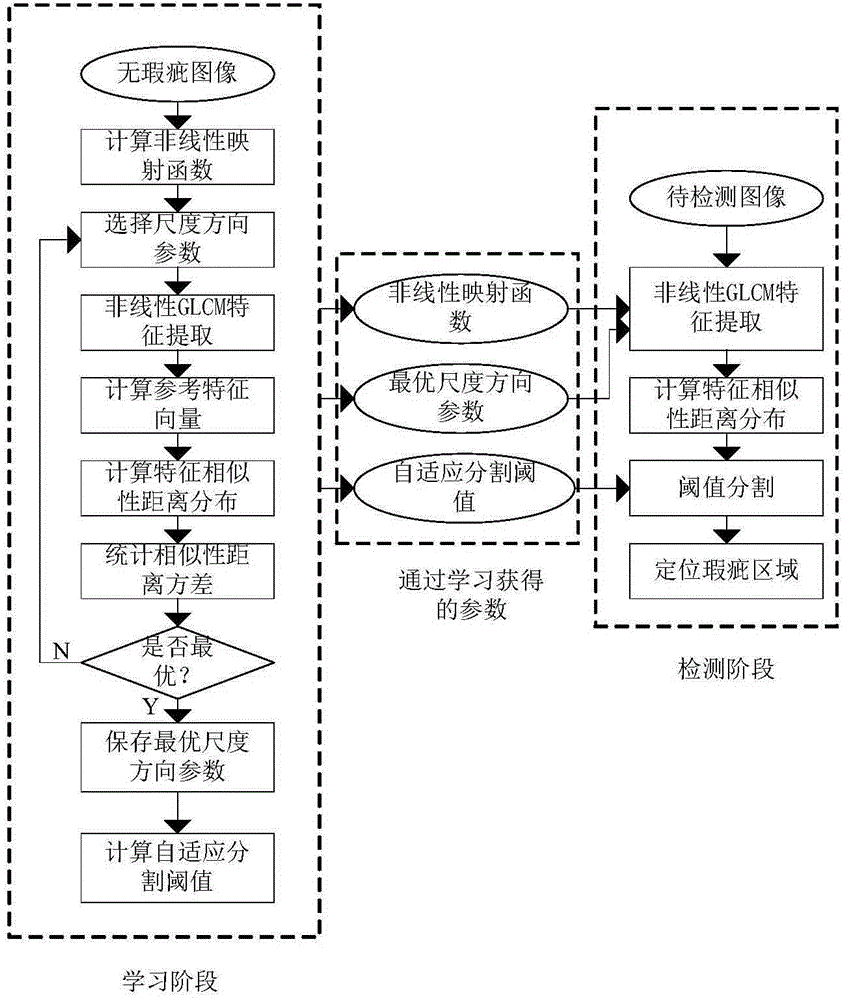

[0035] The method of the invention mainly includes three steps of obtaining nonlinear mapping functions, learning optimal parameters and detecting defects. The specific implementation is as follows:

[0036] 1. The nonlinear mapping function calculation stage

[0037] For fabric images, the gray levels are often concentrated in a certain interval, rather than uniformly distributed in the entire gray space. If the general GLCM feature extraction method is used, linear quantization will be performed, and a large number of quantization values are not or rarely used, resulting in The generated GLCM matrix is very sparse and cannot fully reflect the texture features of the image. The present invention proposes nonlinear GLCM feature extraction. The basic idea is to quantify according to the occurrence probability of gray levels, refine the high-probability gray-scale intervals, and coarsely quantize the low-probability gray-scale intervals, so that image features can be effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com