Fluorescent baking machine drying shaft

A baking machine and fluorescent lamp technology, applied in the field of baking machine components, can solve the problems of accidental breakage of the shaft head, loss of heat energy, affecting normal production, etc., and achieve the effects of avoiding accidental breakage, easy use, and reducing accidental losses.

Inactive Publication Date: 2016-01-27

湖北如日电气股份有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] In the process of producing fluorescent lamps, a baking machine is used to bake the tube body. The traditional equipment uses a stainless steel rotating shaft to bake in rotation. However, since stainless steel is a metal heat-conducting material, the equipment will be baked during the baking process. The internal heat transfers to the outside and causes heat loss. In recent years, equipment manufacturers have used ceramic shafts for metal shafts to avoid heat loss. The use of such ceramic shafts greatly reduces heat loss, but in In actual use, the shaft head at the transmission end of the ceramic shaft is very easy to cause accidental breakage during uninterrupted rotation, which directly affects the normal production

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

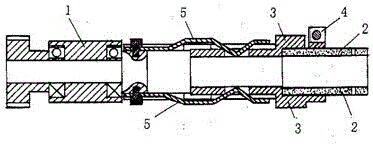

[0010] figure 1 As shown: the outer end of the shaft rod 1 of the drying shaft is connected and fixed with the ceramic shaft 2 through the metal sleeve 3 . The metal sleeve 3 is provided with a screw clip 4 for fastening the ceramic shaft 2 . There is a fastening clip 5 between the shaft rod 1 and the ceramic shaft 2 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The present invention provides a fluorescent baking machine drying shaft. The shaft rod outer end head of the drying shaft and a ceramic shaft are connected and fixed through a metal sleeve. The metal sleeve is provided with a screw clamp which fastens a ceramic shaft, and a fastening card is arranged between a shaft rod and the ceramic shaft. Through connecting the shaft rod and the ceramic shaft by the metal sleeve, the characteristic of reducing thermal energy loss of the ceramic shaft is maintained, and the phenomenon of a loss caused by accidental breakage can be avoided through the metal sleeve.

Description

technical field [0001] The invention relates to a roasting machine component used in producing fluorescent lamps, in particular to a drying shaft of a fluorescent lamp roasting machine. Background technique [0002] In the process of producing fluorescent lamps, a baking machine is used to bake the tube body. The traditional equipment uses a stainless steel rotating shaft to bake in rotation, but since stainless steel is a metal heat-conducting material, the equipment will be baked during the baking process. The internal heat transfers to the outside and causes heat loss. In the equipment transformation in recent years, equipment manufacturers use ceramic shafts for metal shafts to avoid heat loss. The use of such ceramic shafts greatly reduces heat loss, but in In actual use, the shaft head at the transmission end of the ceramic shaft is very easy to cause accidental breakage during uninterrupted rotation, which directly affects the normal production. Contents of the inve...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01J9/24

Inventor 张静霞张小二

Owner 湖北如日电气股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com