Recombinant microorganisms exhibiting increased flux through a fermentation pathway

A technology for recombining microorganisms and microorganisms, applied in the field of identifying and solving reaction bottlenecks in fermentation pathways, and can solve problems such as inability to identify rate-limiting reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0192] Example 1 - Identification of Bottlenecks

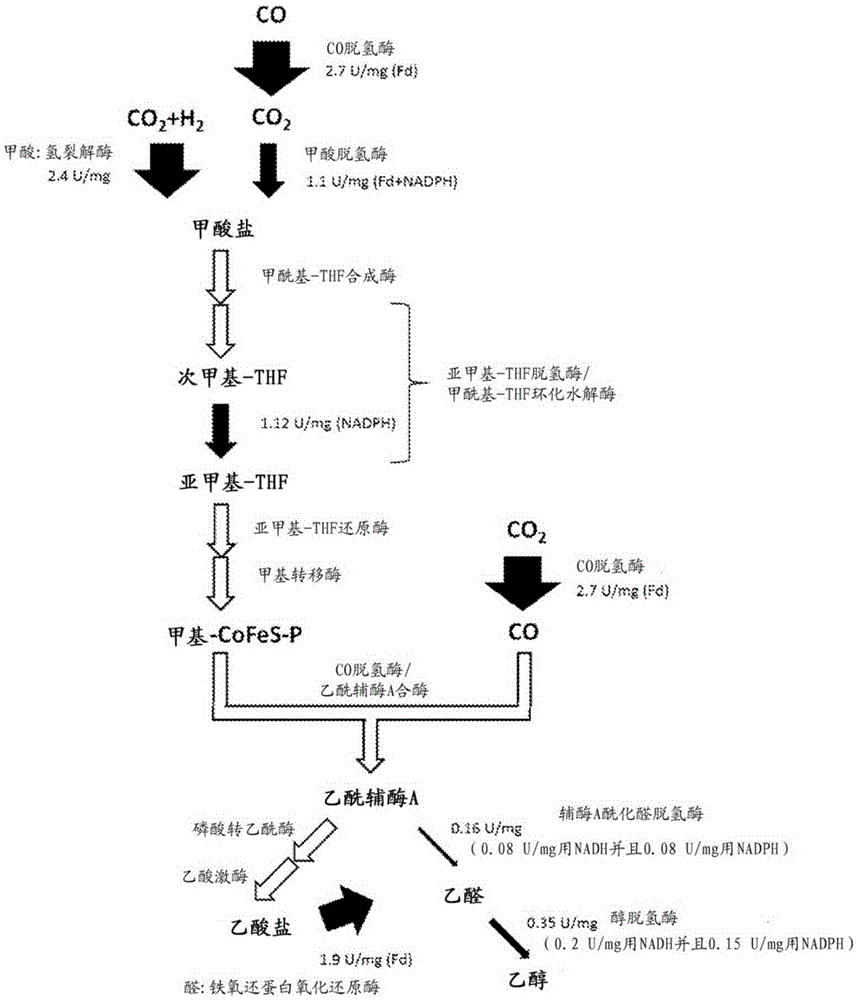

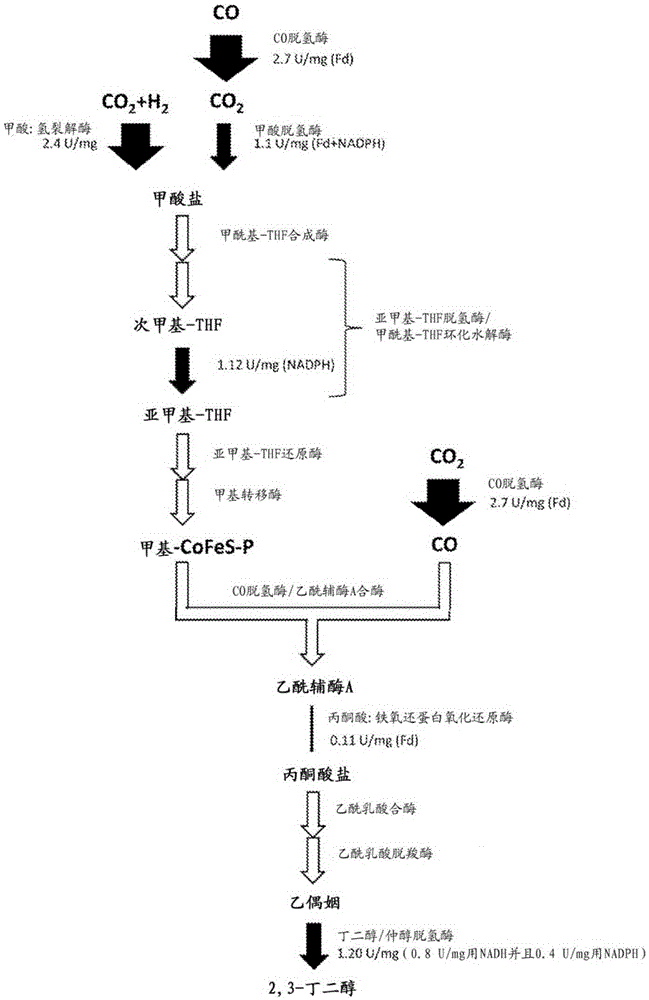

[0193] The fermentation pathways of carboxydotrophic bacteria, such as Clostridium autoethanogenum, Clostridium ljungdahlii, or Clostridium rasseri, for the production of ethanol and 2,3-butanediol were analyzed for bottlenecks using an enzyme assay. For this, oxidoreductase reactions are particularly suitable because they involve one or more cofactors whose reduction or oxidation can be measured. Synthetic redox dyes such as methyl viologen or benzyl viologen can also be used for this purpose.

[0194] The oxidoreductase steps of the Wood-Yendal pathway and the fermentative pathways producing ethanol and 2,3-butanediol were assayed to determine their activity. Enzymes in these pathways are involved in autotrophic growth (including CO, CO 2 and H 2 gas absorption and utilization) and product formation.

[0195] The enzymes assayed and their activities are detailed in figure 1 middle. All assays performed were tested usi...

Embodiment 2

[0214] Example 2: Bottleneck of ethanol production

[0215] as in figure 1 As seen in the ethanol fermentation pathway depicted in , the bottleneck for ethanol production is the alcohol dehydrogenase reaction. While all other measured reactions showed at least 1.1 U / mg activity, the alcohol dehydrogenase reaction step only had a total activity of 0.35 U / mg (or 31%), i.e. 0.2 U / mg (18%) with NADH and 0.15U / mg (13%) with NADPH. This is 69% smaller than all other reactions in the pathway. In a similar manner, the aldehyde dehydrogenase reaction had only 0.16 U / mg (14%) of total activity, ie 0.08 U / mg (7%) with NADH and 0.08 U / mg (7%) with NADPH. This is 86% smaller than all other reactions in the pathway. However, this reaction can be bypassed via acetate and aldehyde:ferredoxin oxidoreductase (AOR), which has an activity of 1.9 U / mg and has Phosphorylation of the substrate level in the reaction produces ATP, which provides the cell with the advantage of more energy. To he...

Embodiment 3

[0216] Example 3: Improving flux through ethanol production pathways by removing bottlenecks

[0217] The reactions catalyzing the conversion of acetyl-CoA to acetaldehyde and the conversion of acetaldehyde to ethanol have been identified as the rate-limiting steps in the formation of ethanol in Clostridium autoethanogenum, Clostridium ljungdahlii or Clostridium rasseri. This can be overcome by:

[0218] i. overexpressing a native bifunctional alcohol / aldehyde dehydrogenase,

[0219] ii. expressing a heterologous bifunctional alcohol / aldehyde dehydrogenase, or

[0220] iii. Expressing a heterologous aldehyde dehydrogenase and alcohol dehydrogenase.

[0221] These results can be achieved by using the methods described below.

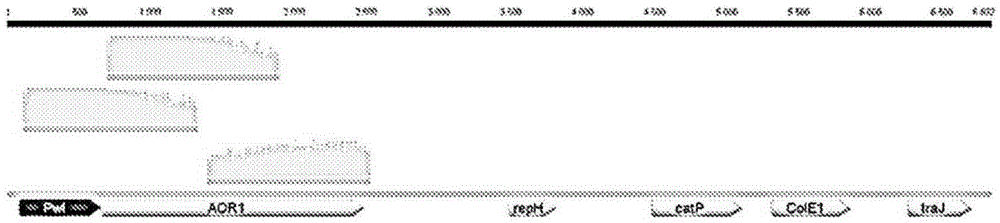

[0222] Overexpression of a native bifunctional alcohol / aldehyde dehydrogenase in Clostridium autoethanogenum

[0223] Selective overexpression of the native bifunctional alcohol / aldehyde dehydrogenase gene (SEQ ID NO: 1) of Clostridium autoethanologen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com