A flexible multi-joint surgical microinstrument for robot-assisted minimally invasive surgery

A robot-assisted, minimally invasive surgery technology, used in surgical robots, surgical forceps, etc., to achieve the effects of convenient positioning, improved working range and flexibility, and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

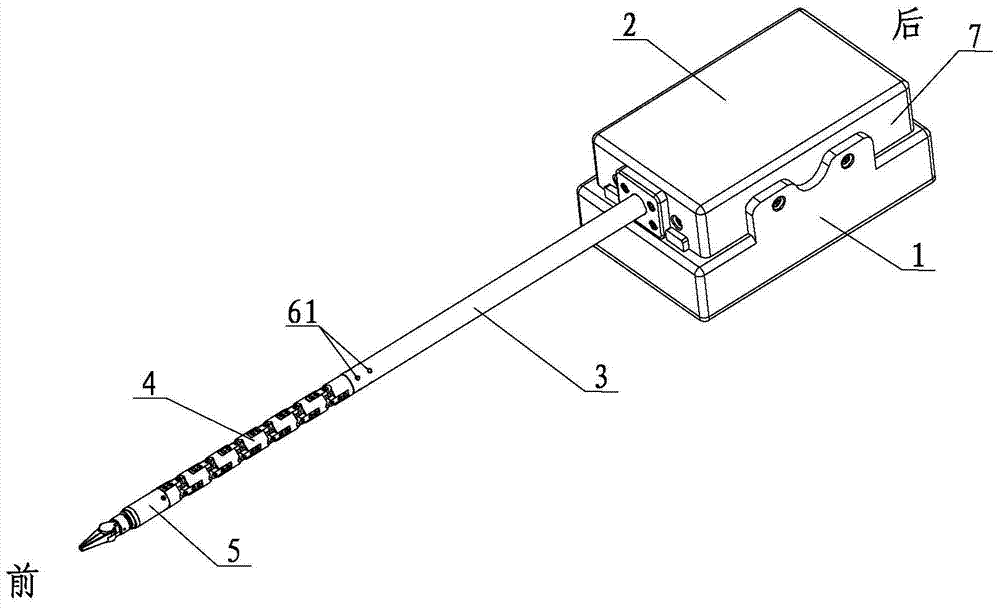

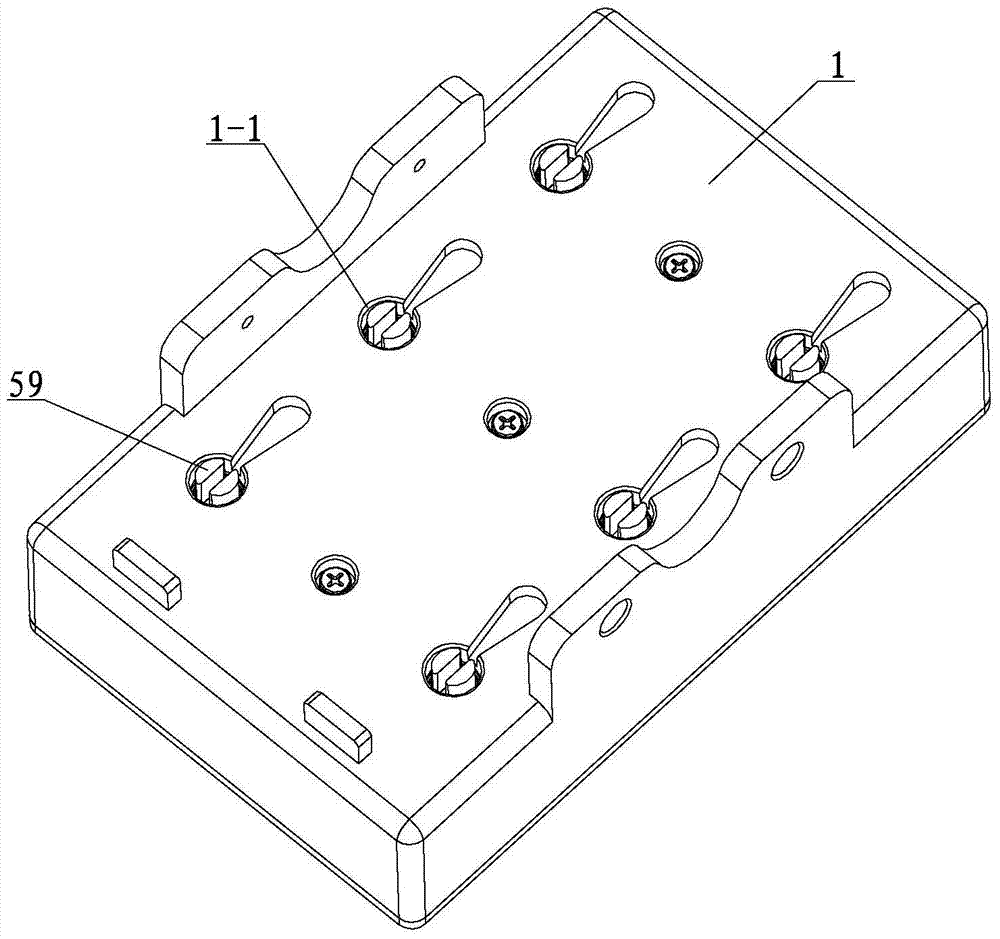

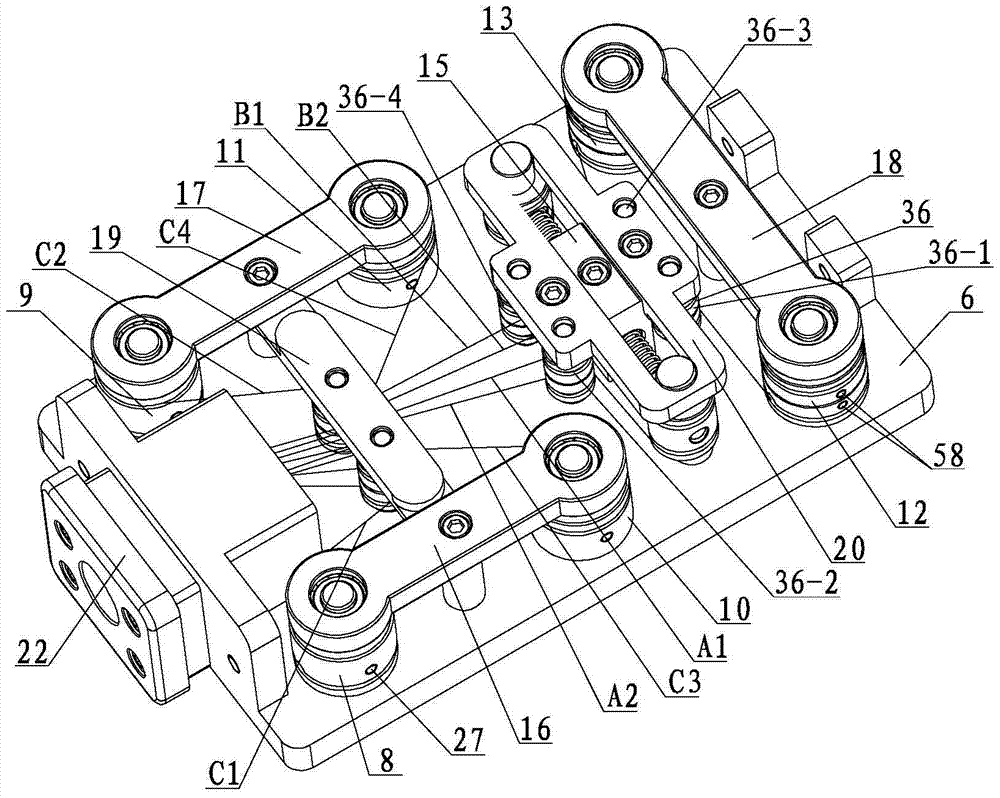

[0025] Specific implementation mode one: combine Figure 1 to Figure 11 Explain that this embodiment includes a drive box 1, a transmission mechanism 2, a catheter 3, a flexible bending arm mechanism 4, a forceps mechanism 5, six transmission parts 59 and six miniature drive motors, and the transmission mechanism 2 includes a bottom plate 6, an upper cover 7, First bending transmission mechanism 8, second bending transmission mechanism 9, third bending transmission mechanism 10, fourth bending transmission mechanism 11, surgical forceps opening and closing transmission mechanism 12, surgical forceps rotation transmission mechanism 13, two bending guide mechanisms 14, The decoupling mechanism 15, the first top plate 16, the second top plate 17, the third top plate 18, the fourth top plate 19, the fifth top plate 20, the conduit fixing part 21 and the conduit baffle plate 22, the upper and lower end surfaces of the bottom plate 6 are provided with the first installation Hole 6-1...

specific Embodiment approach 2

[0026] Specific implementation mode two: combination image 3 and Figure 5 Describe this embodiment, the first bending transmission mechanism 8 of this embodiment, the second bending transmission mechanism 9, the third bending transmission mechanism 10 and the fourth bending transmission mechanism 11 are all composed of a bending transmission shaft 23, a bending transmission wheel 24, a bending transmission The upper bearing 25, the lower bearing 26 of the bending transmission and two first set screws 27 are composed. The bending transmission shaft 23 is a stepped shaft. -2. The third section 23-3 of the curved transmission shaft and the fourth section 23-4 of the curved transmission shaft, wherein the front and rear sides of the section 23-1 of the curved transmission shaft are respectively provided with square flats, and the inner ring of the lower bearing 26 of the curved transmission is installed on the curved On the outer wall of the second section 23-2 of the transmiss...

specific Embodiment approach 3

[0027] Specific implementation mode three: combination Figure 6 Describe this embodiment, the surgical forceps opening and closing transmission mechanism 12 and the surgical forceps rotation transmission mechanism 13 of this embodiment are all composed of a terminal drive shaft 28, an end drive upper bearing 30, a terminal drive lower bearing 31, two terminal drive wheels 29 and four A second set screw 58 is formed, and a second annular wire groove (29-1) is provided on the outer surfaces of the two end drive wheels (29), and the two second annular wire grooves (29-1) are provided on the outer surfaces of the two end drive wheels (29). 1) Parallel to each other, between the two second annular steel wire grooves 29-1 is a wide transmission wheel 29-3, the upper and lower ends of the two second annular steel wire grooves 29-1 are narrow transmission wheels 29-2, and the wide transmission wheel 29- 3 A second concave hole 29-4 is provided near the edge of the second annular wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com