Gas purifier

A gas purifier, a technology for purifying gas, applied in chemical instruments and methods, separation methods, transportation and packaging, etc., can solve the problems of filter cotton or activated carbon pore blockage, affecting filtration performance, etc., to improve filtration effect and improve the effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

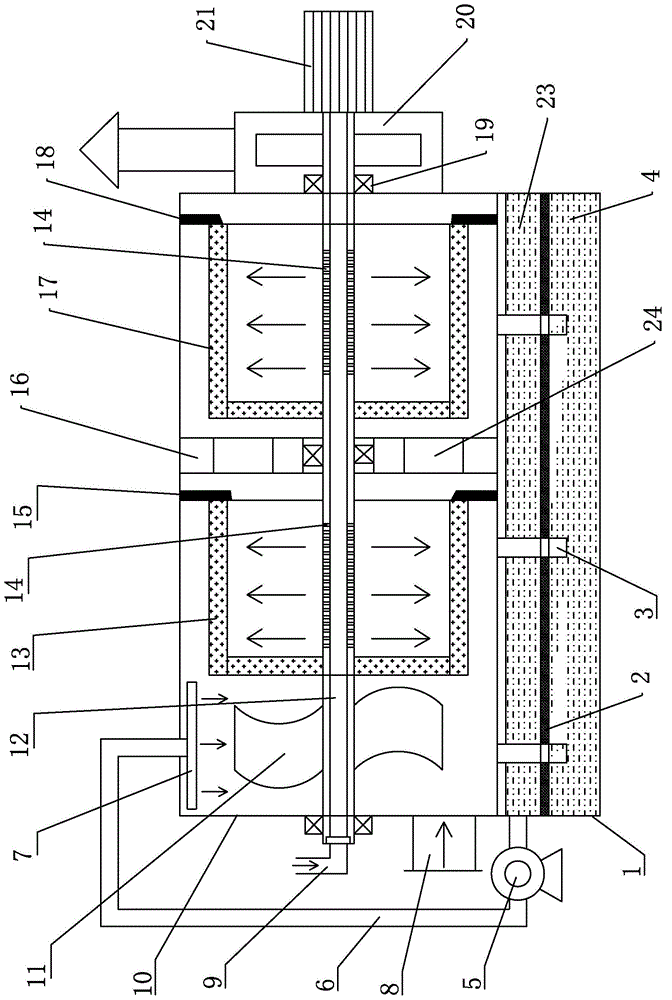

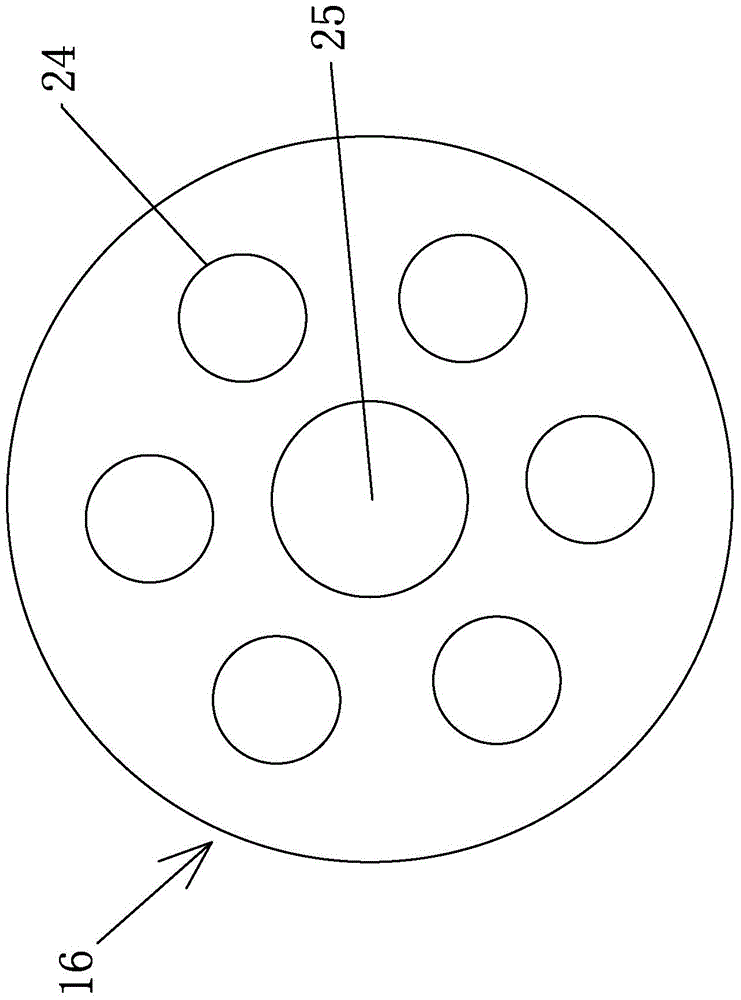

[0014] like figure 1 As shown, the gas purifier of the present invention includes: a water storage tank 1, a filter layer 2, a return pipe 3, a sewage layer 4, a water pump 5, a water pipe 6, a shower 7, an air inlet pipe 8, an water inlet pipe 9, a housing 10, Rotary filter screen 11, hollow shaft 12, filter cartridge 13, spray hole 14, sealing mechanism 15, bracket 16, filter cartridge 2 17, sealing mechanism 2 18, bearing 19, induced draft fan 20, motor 21, water purification Layer 23, wind hole 24, shaft hole 25.

[0015] In the water storage tank 1, from top to bottom, there are respectively a water purification layer 23, a filter layer 2 for filtering particulate matter, and a sewage layer 4, and the bottom of each return pipe 3 is connected to the sewage layer; The connected water outlet is connected to the sprinkler 7 through the water pump 5; a cylindrical shell 10 is arranged above the water storage tank 1, and the hollow shaft 12 is horizontally fitted in the shell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com