Bed binding strip driver

A binding strip and driving machine technology, applied in the direction of conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of lower production efficiency, easy fatigue, unfavorable product output value, etc., to improve production efficiency and product quality, reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with embodiment the present invention is further described.

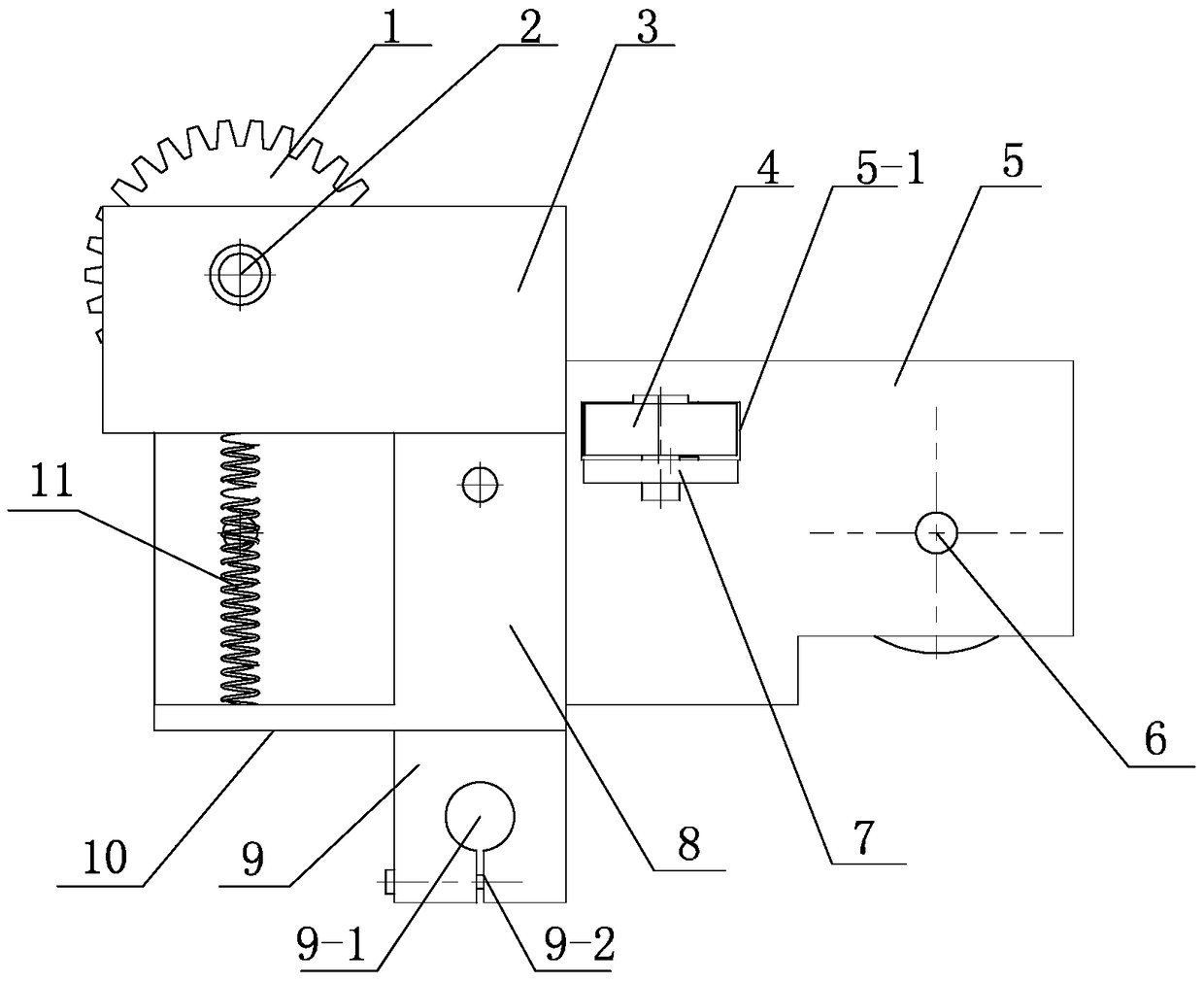

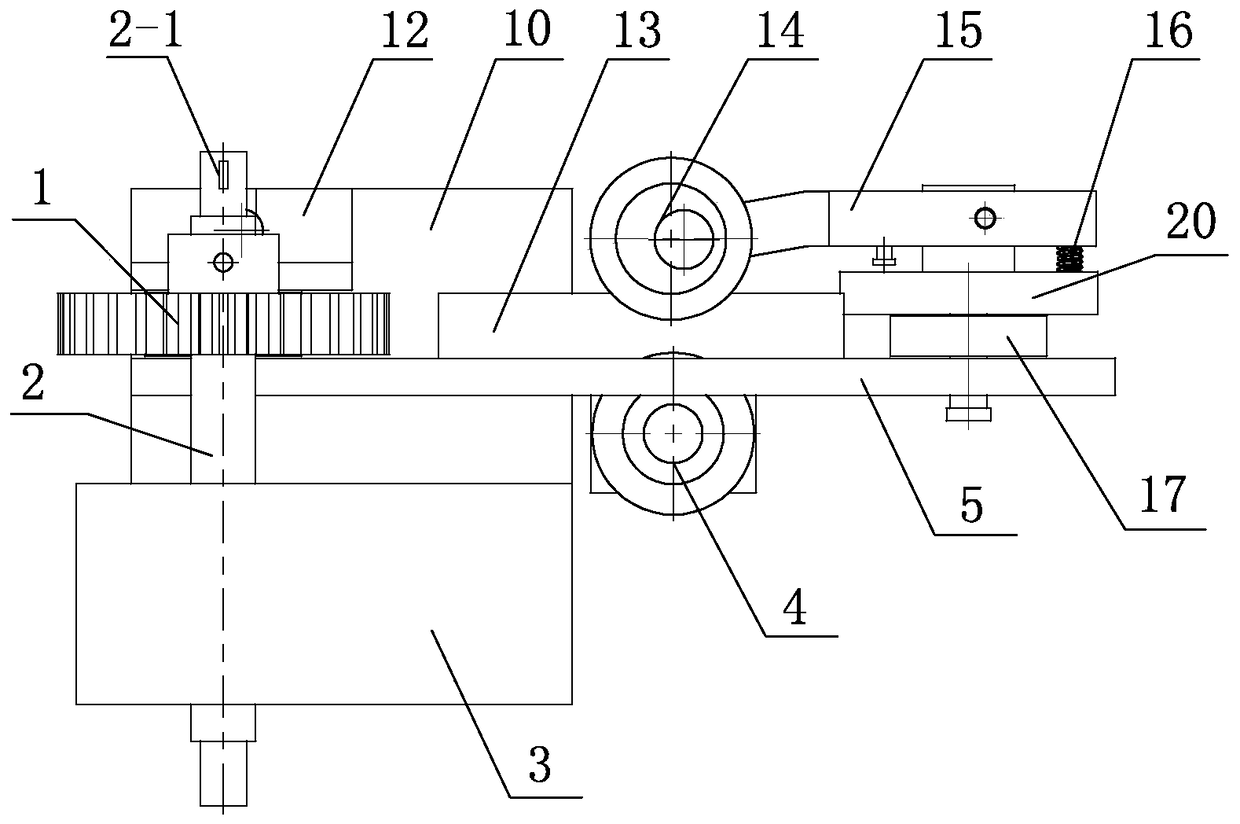

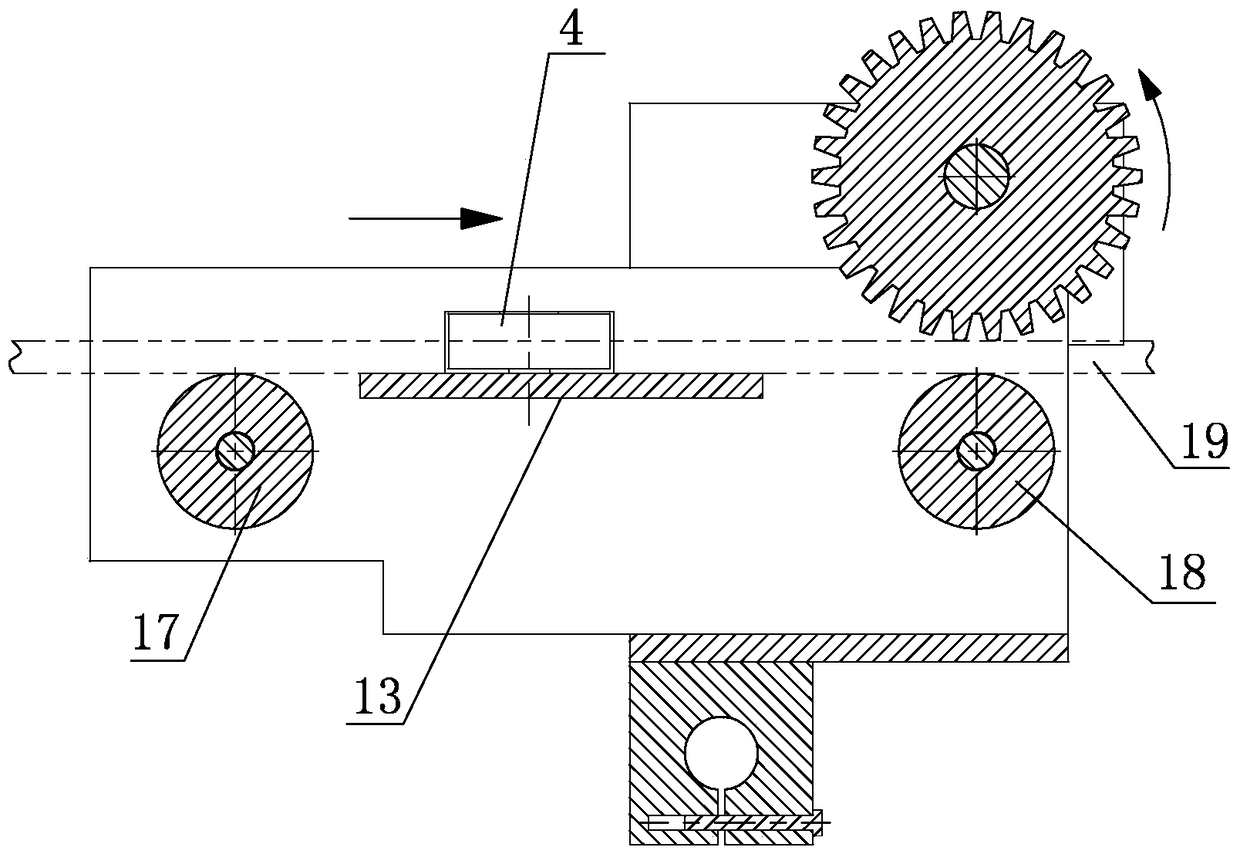

[0024] As shown in the drawings, a bed board binding strip driving machine includes a bottom plate 10, a vertical plate 5 is fixed on the bottom plate 10, and a front vertical guide wheel 18 and a rear vertical guide wheel 18 are installed on one side of the vertical plate 5. Wheel 17, guide bar 13 is fixed on the vertical plate of front vertical guide wheel 18 and rear vertical guide wheel 17, and the top of described front vertical guide wheel 18 and rear vertical guide wheel 17 is flush with guide bar 13 Or slightly higher, slightly higher here means to ensure that the binding strip can touch the front vertical guide wheel 18 and the rear vertical guide wheel 17, which is clear to those skilled in the art. The outer side of the rear vertical guide wheel 17 is equipped with a baffle plate 20, and the baffle plate 20 is fixed on the vertical plate 5 through the mandrel 6, and the outer s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com