Conveying device used for sheet glass production

A technology of transportation device and flat glass, which is applied in the direction of transportation and packaging, conveyor objects, furnaces, etc. It can solve the problems of short service life of packaging materials, difficulty in fixing, and low transportation efficiency, so as to increase service life, facilitate operation and control, The effect of easy access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

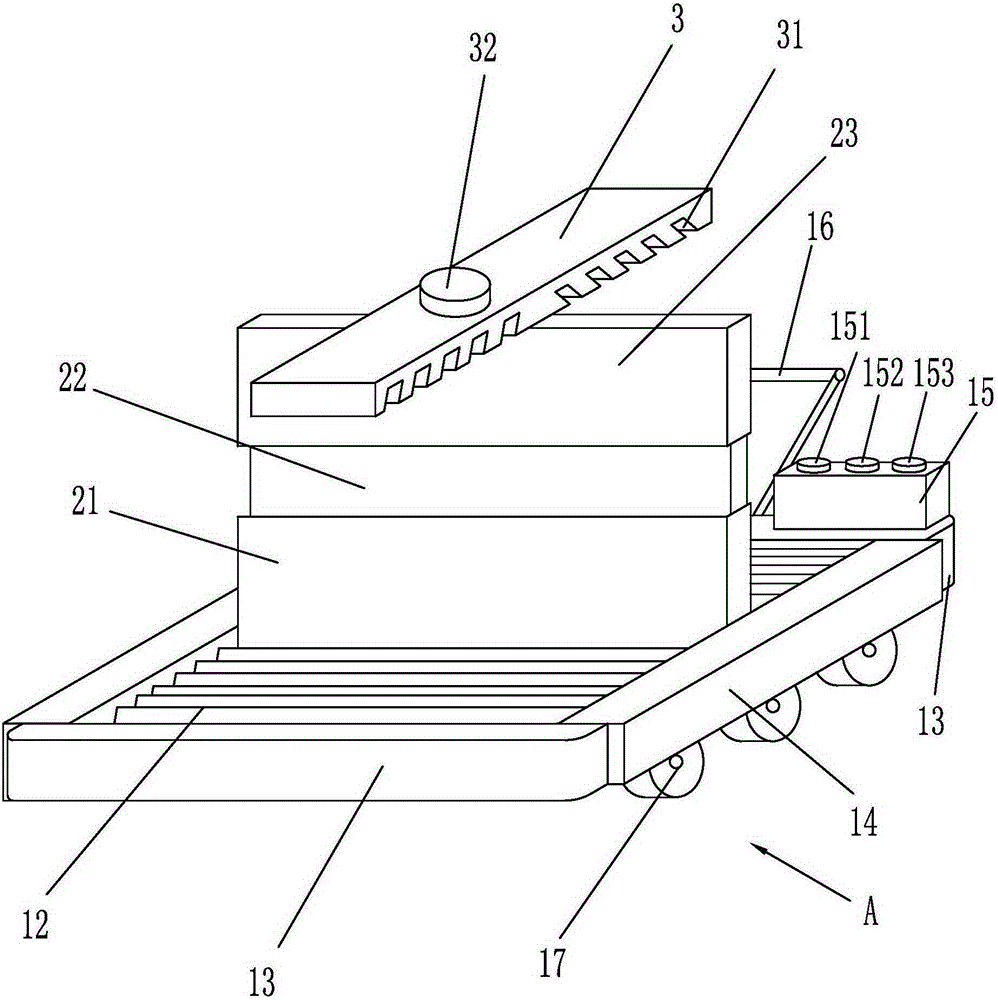

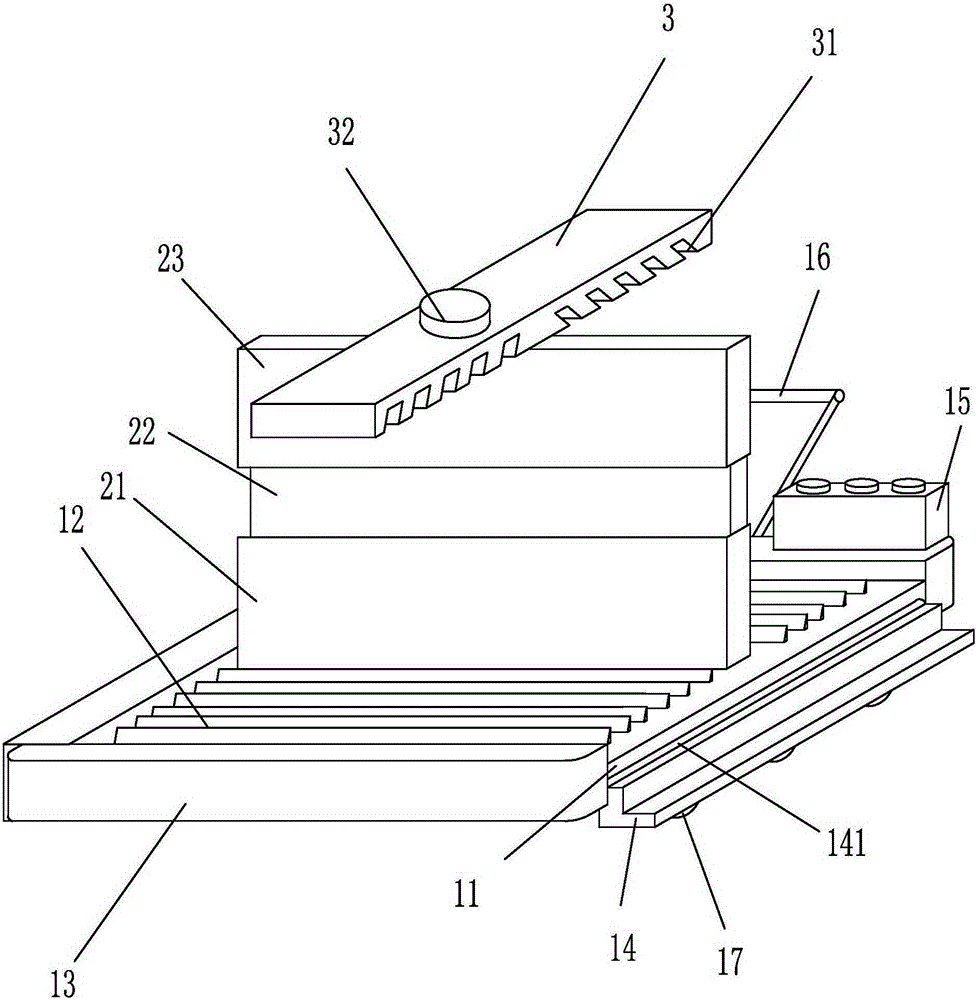

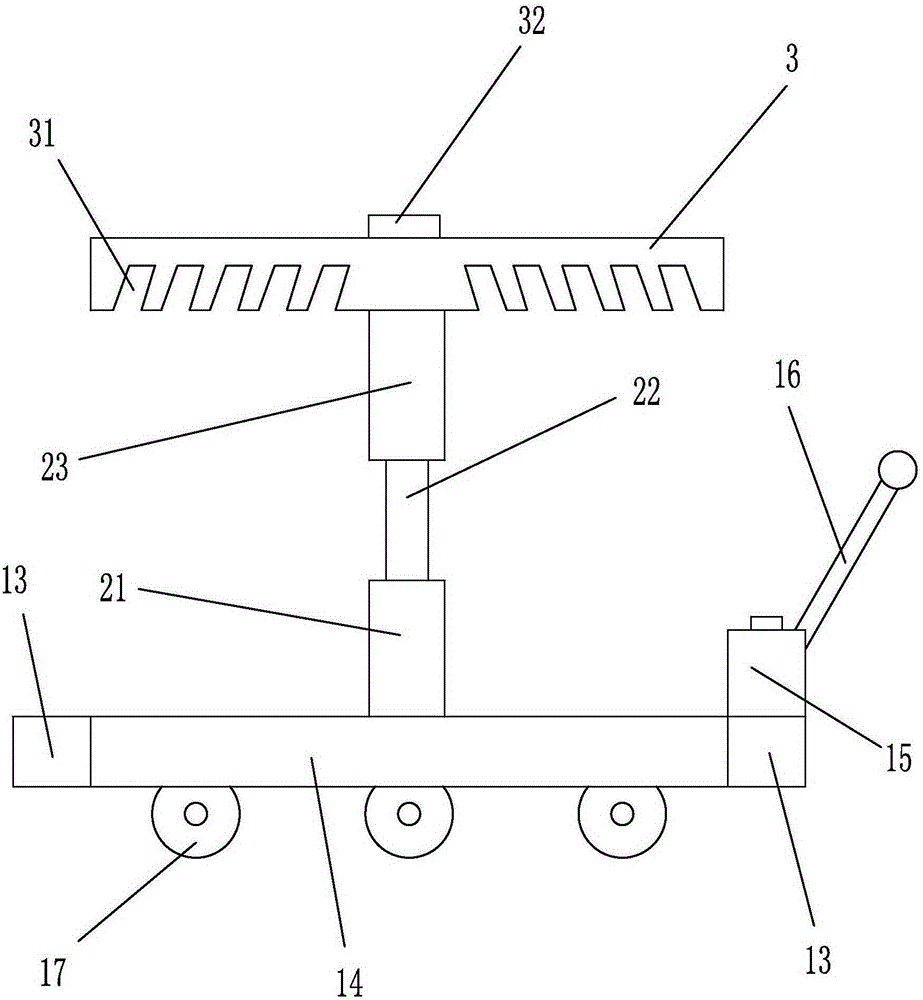

[0026] Such as Figure 1 to Figure 5 As shown, a transport device for the production of flat glass includes a transport seat, a telescopic support plate and a positioning plate 3. A telescopic support plate is fixed in the transport seat, and a positioning plate 3 is fixed on the upper end of the telescopic support plate. The transport seat includes a transport Plate 11, positioning partition 12, protective frame 13, and switch frame 14. The transportation plate 11 is provided with positioning partitions 12, which are located on both sides of the telescopic support plate. The number of positioning partitions 12 is at least 12. The protective frame 13 is fixedly connected to the front and rear sides of the transport plate 11, and the protective frame 13 is provided with a push-hand handle 16. Through the setting of the push-hand handle 16, it is convenient for the user to hold the push-hand handle 16 in both hands during the transportation process to carry out the transportation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com