Four-guide-column type lifting machine

A technology of lifts and four guide columns, applied in the direction of lifting frames, lifting devices, etc., can solve problems such as risks and poor operation stability, and achieve the effect of simple and reliable structure, stable operation, and synchronous lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with specific examples.

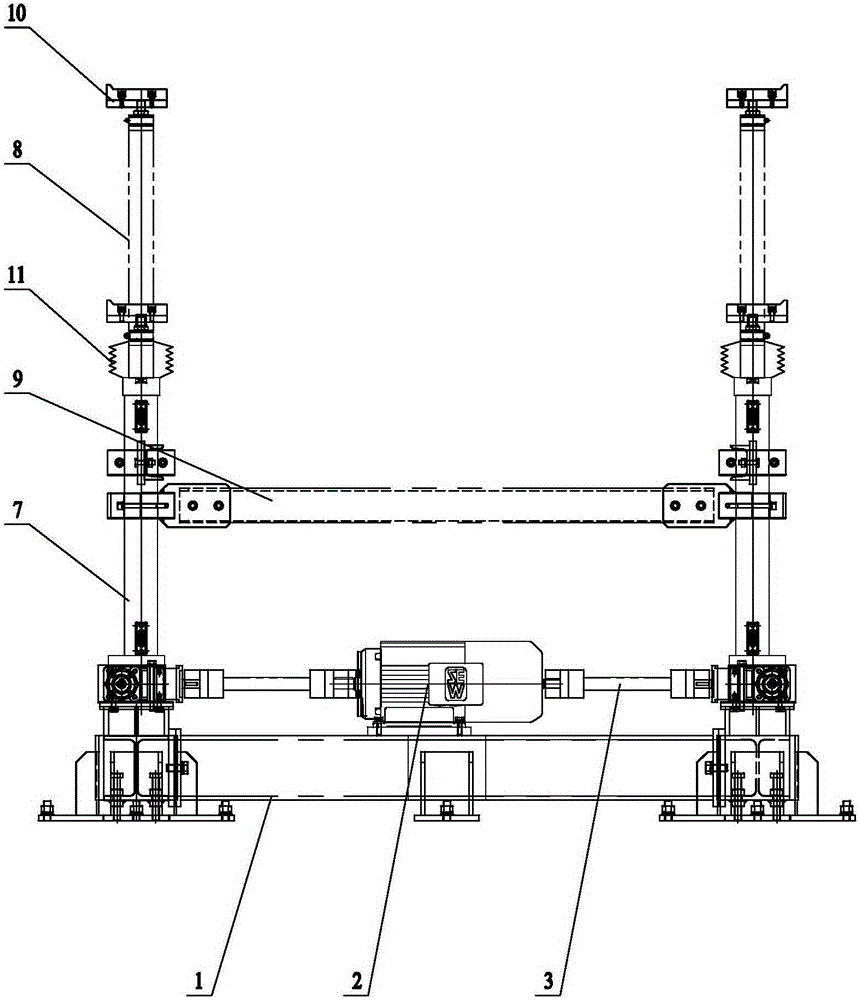

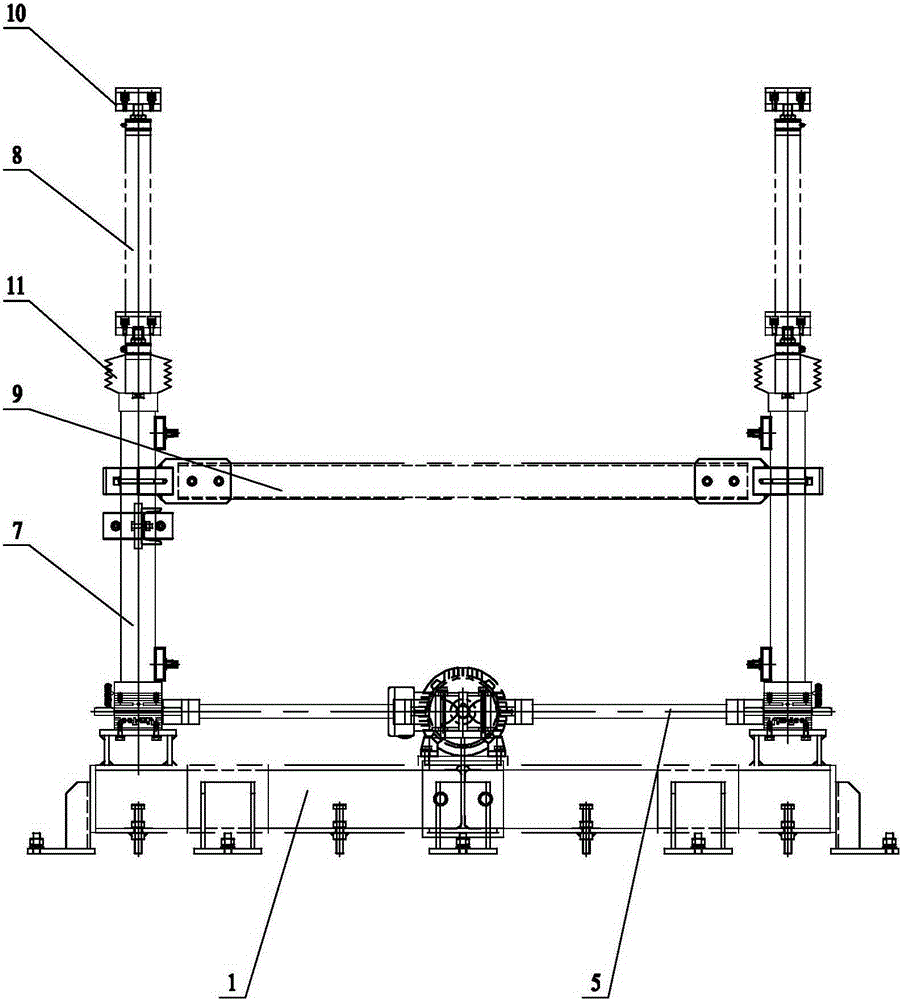

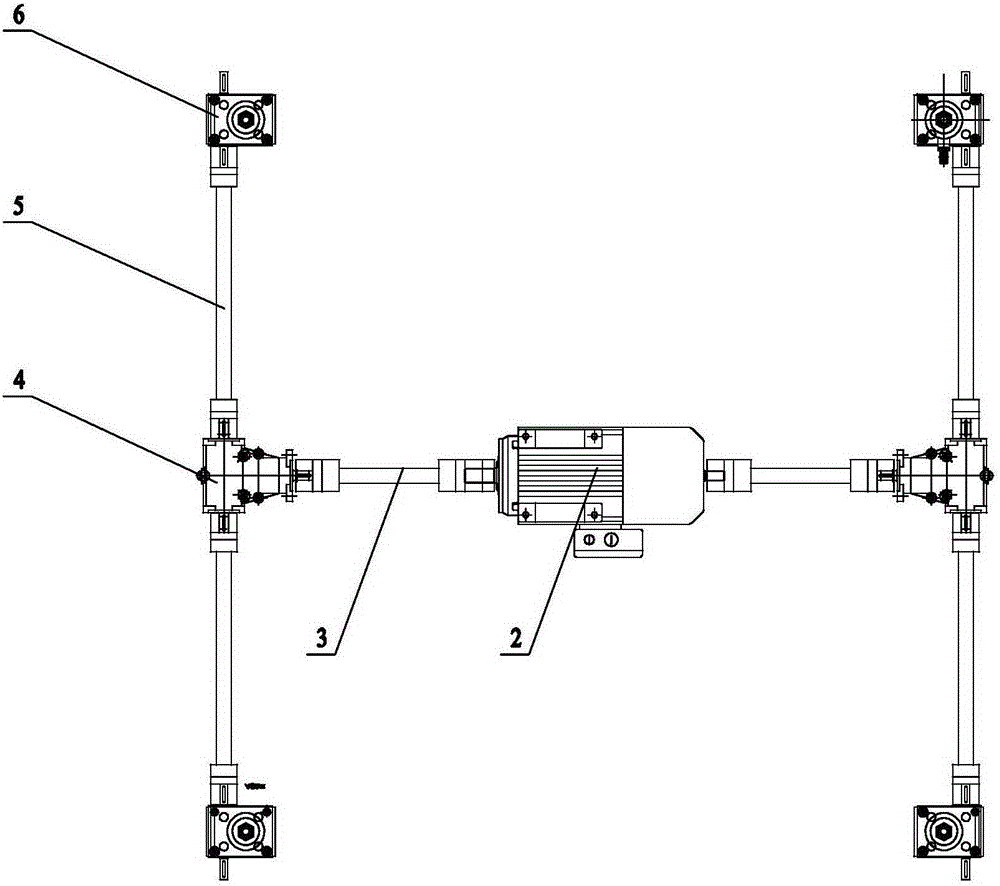

[0013] The four-column lift includes a base 1, a two-way output shaft motor 2, a first coupling 3, a commutator 4, a second coupling 5, a transmission box 6, a guide sleeve 7 and a guide column 8, and on the base 1 is fixed with a two-way output shaft motor 2 and four transmission boxes 6, the transmission box 6 has a screw input shaft, a guide sleeve 7 is fixed on each transmission box 6, and a guide column 8 is slidably installed in the guide sleeve 7, The bottom end of the guide column 8 is processed with external threads, and the bottom end of the guide column 8 is matched with the screw input shaft of the transmission box 6 through threads, and the centers of the four transmission boxes 6 are located on the four vertices of the same rectangle, and the two-way output shaft The motor 2 is located at the center of the rectangle where the four transmission boxes 6 are located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com