Preparation method of sodium ethoxide

A technology of sodium ethoxide and anhydrous ethanol is applied in the preparation of ethoxylation agents, the fields of strong basic catalysts in medicine and pesticide industry, and can solve the problems of high production cost, low yield, etc. The effect of simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

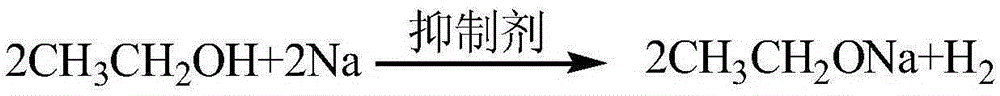

Image

Examples

Embodiment 1

[0017] Add 100kg of sodium metal and 1kg of inhibitor to the reaction kettle, start stirring, open the vacuum valve, keep the vacuum at -0.01MPa, raise the temperature to 25°C, start adding 1000kg of absolute ethanol dropwise, control the dropping time for 2h, and control the temperature At 25-30°C; after the dropwise addition, continue to keep warm at 25-30°C for 2 hours. After the reaction, 1055kg of the product is obtained, with a yield of 95.91% and a content of 27.96%. It is a colorless viscous liquid.

Embodiment 2

[0019] Add 100kg of sodium metal and 3kg of inhibitors to the reaction kettle, start stirring, open the vacuum valve, keep the vacuum at -0.01MPa, cool down to 10°C, start adding 1200kg of absolute ethanol dropwise, control the dropping time for 3h, and control the temperature At 10-15°C; after the dropwise addition, continue to keep warm at 10-15°C for 2 hours. After the reaction, 1270kg of the product is obtained, the yield is 97.62%, the content is 23.23%, and it is a colorless viscous liquid.

Embodiment 3

[0021] Add 100kg of sodium metal and 5kg of inhibitors to the reaction kettle, start stirring, open the vacuum valve, keep the vacuum at -0.05MPa, raise the temperature to 30°C, start adding 1400kg of absolute ethanol dropwise, control the dropping time for 3h, and control the temperature At 15-25°C; after the dropwise addition, continue to keep warm at 15-25°C for 3 hours. After the reaction is completed, 1410kg of the product is obtained, with a yield of 94.01% and a content of 20.92%. It is a colorless viscous liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com