Elastic damage-free speed hump for vehicles

A non-damaging, decelerating arch technology, applied in roads, buildings, road signs, etc., can solve the problems of high production cost, difficult maintenance, and difficult promotion and application of hydraulic cylinders, achieve low production cost and use cost, and improve comfort , taking into account the effect of comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

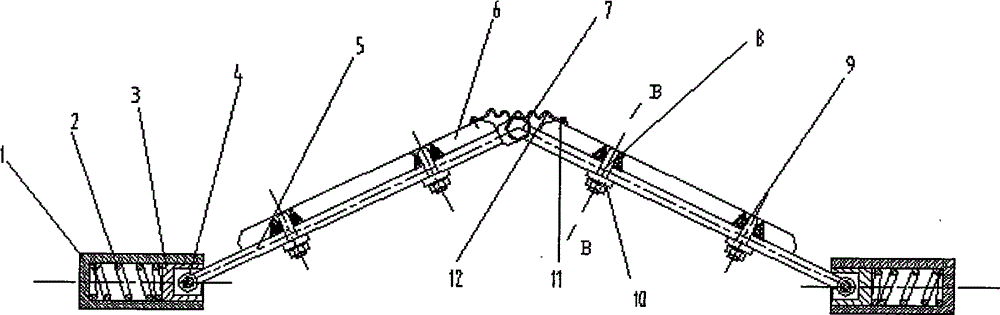

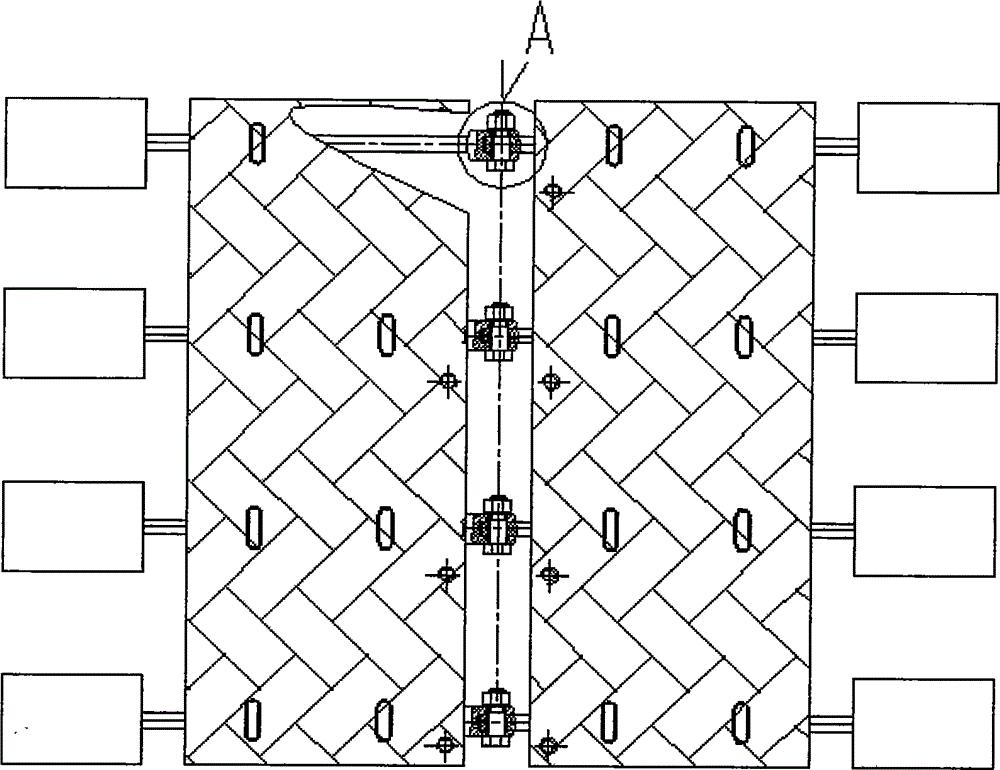

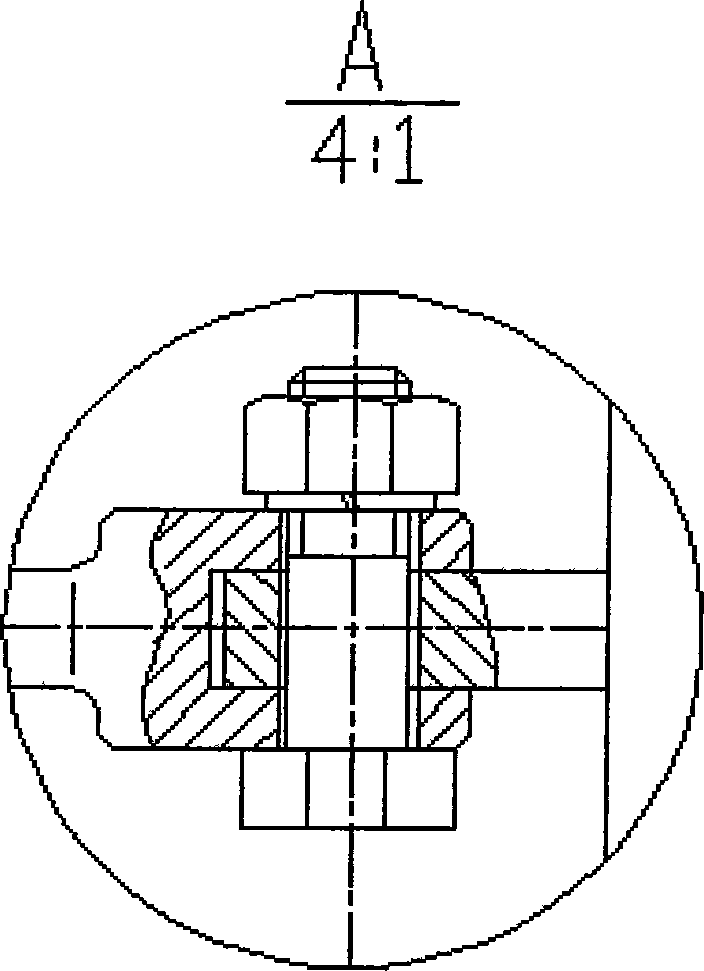

[0019] see figure 1 and figure 2 , an elastic and non-damaging vehicle deceleration arch, including two pressure plates 6 connected with the linkage mechanism to realize folding and arching, and two sets of connecting rods 5 hinged to each other are arranged at the bottom of the pressure plate 6, as image 3 As shown, one end of the corresponding connecting rods between the two groups of connecting rods is hinged to each other through the pin bolt 7, and the other end is hinged to a slider 3 through the connecting pin 4. The chute slides, and a compression spring 2 is provided inside the chute seat 1 to connect with the slide block 3 . The joint of the two pressure plates 6 is provided with a flexible telescopic cover 12 through the screw 11, so as to prevent sundries on the road from entering the bottom of the pressure plates through the gap between the pressure plates, or stones on the road are stuck between the pressure plates, causing the deceleration arch to malfunction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com