Hull Damaged Oil Spill Near Body Emergency Oil Containment Boom

A technology for oil booms and hulls, which is applied in water conservancy projects, cleaning of open water surfaces, and general water supply conservation, etc. It can solve the problems of greatly increased length of oil booms, inconvenient portability on board, and increased deployment time, making it easy to repeat Use, save deployment time, and store effects that take up little space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

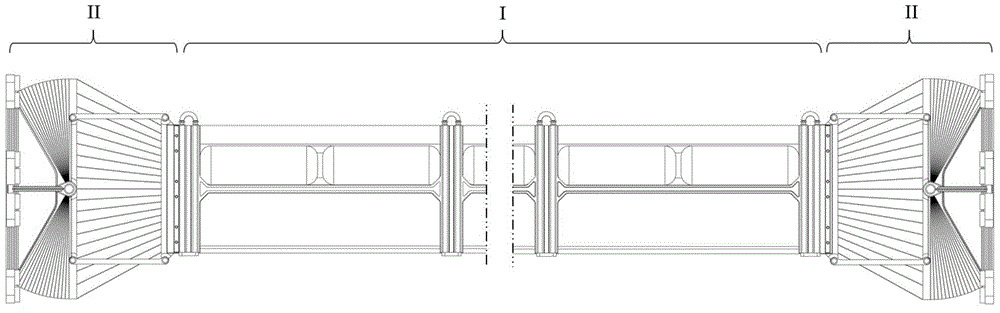

[0026] combined with figure 1 , the present invention comprises self-inflating type oil containment boom main body I and electromagnetic adsorption type hull connector II two parts, use quick connector to realize connection between two parts, if the length of a section of oil containment boom main body I is not enough, also can according to need A plurality of oil boom main bodies 1 are connected in series through quick connectors to obtain a sufficient length of oil boom main bodies.

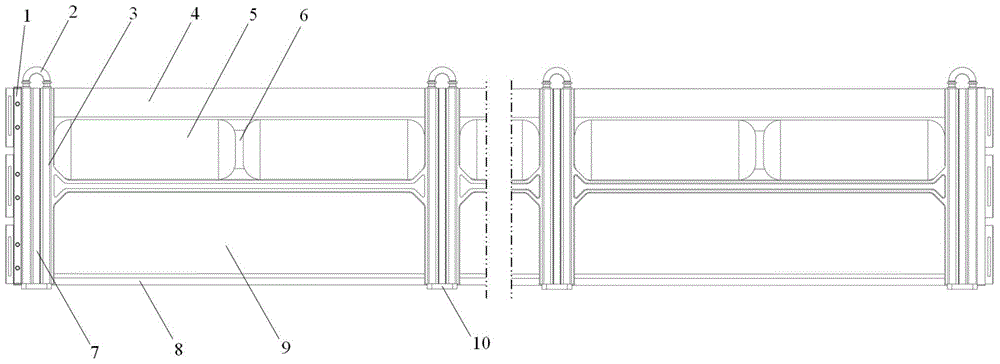

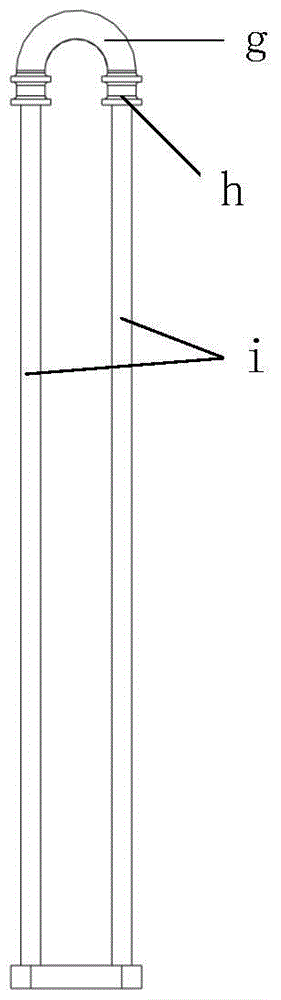

[0027] Such as figure 2As shown, the main body of the oil boom consists of a first quick connector 1, an inverted U-shaped shaft ("∩"-shaped shaft) 2, an "H"-shaped frame 3, an upper skirt 4, an air bag floating body 5, a gas generator 6, a flexible Partition 7, counterweight lead rod 8, lower skirt body 9 and limit connecting rod 10 and other compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com