Adaptive load compensation for an industrial machine

An industrial machinery, suspended load technology, applied in mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., can solve problems such as pressure strain and loss of industrial machinery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

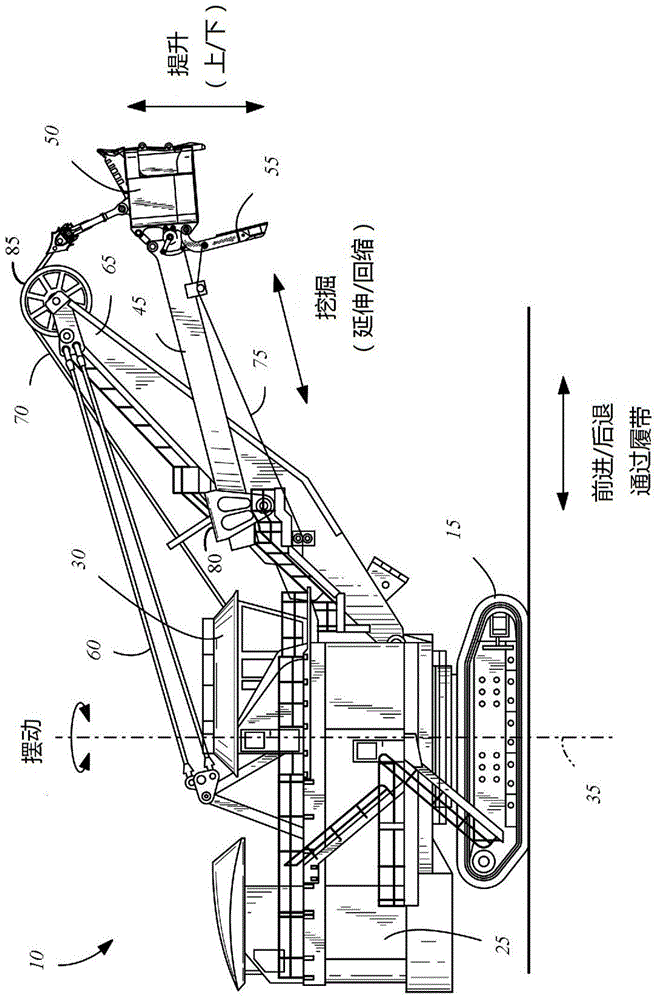

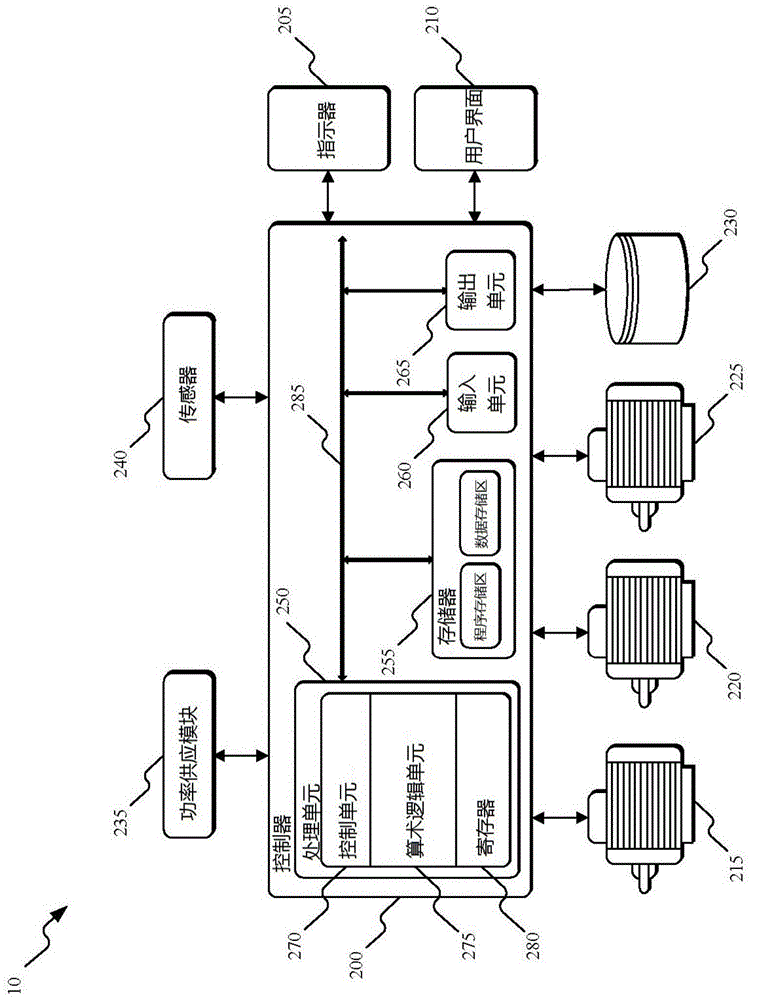

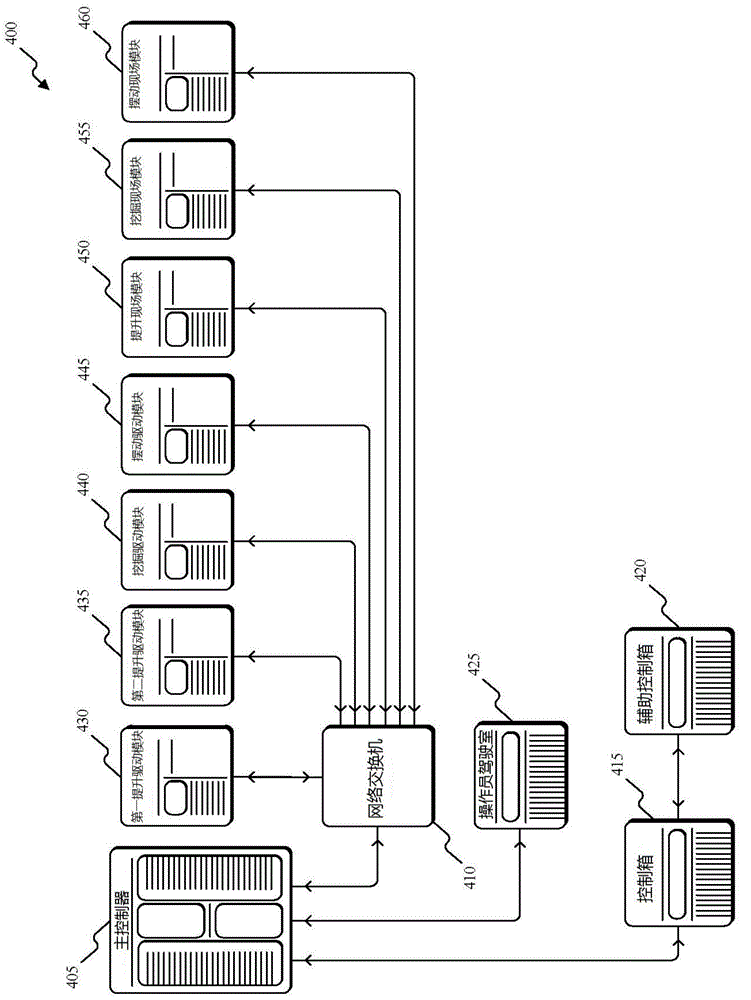

[0019] The invention described herein relates to systems, methods, apparatus, and computer readable media associated with controlling the operation of industrial machinery based on a suspension of the industrial machinery. For example, the industrial machine includes a control system or controller that determines and / or monitors the suspended load. The suspended load of the industrial machine includes the weight of the bucket and the weight of the materials in the bucket. The controller is configured to determine and / or monitor the suspended load of the industrial machine for individual excavation operations and excavation operations for a period of time. If at any given time the controller determines that the suspended load (e.g., the instantaneous suspended load) is greater than or equal to a threshold (e.g., the rated suspended load "RLS"), the controller can control the suspended load based on the suspended load. Describe industrial machinery. For example, the controller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com