T-shaped formwork for ramming

A technology for ramming and formwork, which is applied in the field of T-shaped formwork for ramming and building, which can solve the requirement of high impact resistance of ramming formwork, cannot solve the problem of one-time ramming of adjacent walls, small height and length of walls, etc. problem, to achieve the effect of simple and easy process, good rigidity and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

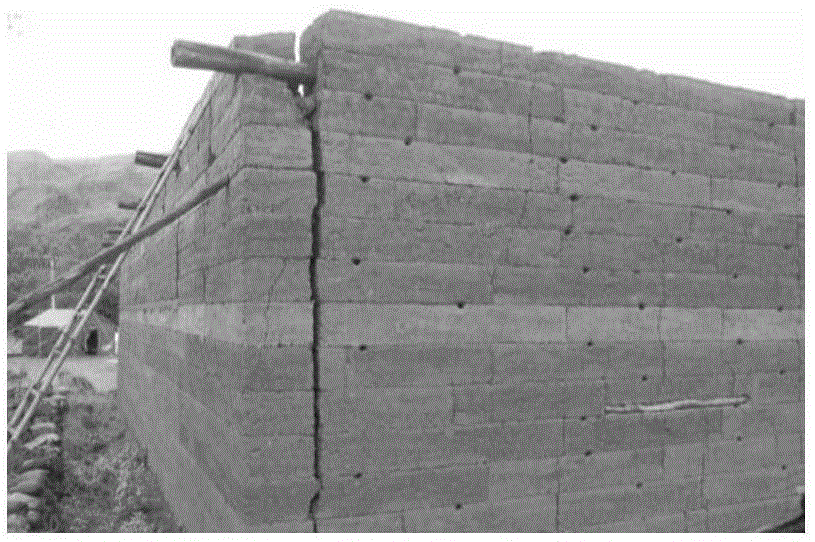

[0065] Such as Figure 17 As shown, the inventor used the formwork system of this embodiment to complete the tasks of the Ministry of Housing and Urban-rural Development, such as the Green Residential Demonstration Project of Macha Village of the Ministry of Housing and Urban-Rural Development.

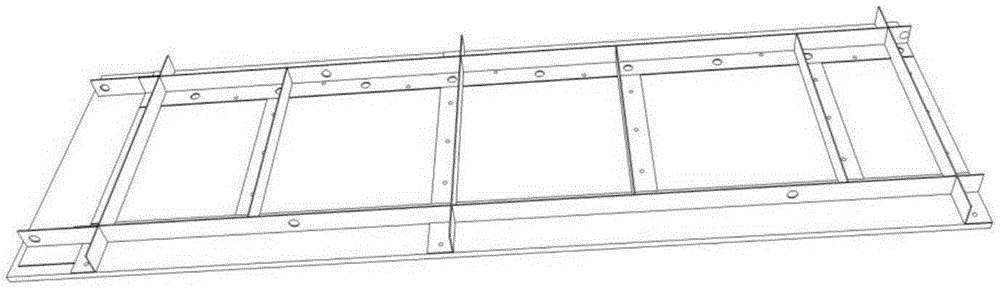

[0066] Ao board is 2295mm*600mm, Ai board is 1880mm*600mm, Bo board is 1865mm*600mm, Bi board is 1450mm*600mm, DC terminal board is 400mm*510mm, DD terminal board is 400mm*600mm. The above dimensions are only calculated based on the bamboo glue board, excluding the size of the section steel on the outer wall.

[0067] The steel frame is made of angle steel, the thickness of the bamboo plywood is 15mm, and the section steel frame is made of 50*50*3mm angle steel. The two are connected by countersunk screws. In order to improve the stability of the connection between the steel frame and the bamboo plywood, the countersunk head The screw arrangement should be staggered alternately (see templa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com