Formwork for cast-in-place concrete stair steps

A technology for concrete and stairs, which is applied to formwork/formwork/work frame, on-site preparation of building components, construction, etc., can solve the problems of slow setting speed, low precision of formwork, affecting the construction of other types of work, etc. The effect of fast setting speed and high precision of mold support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

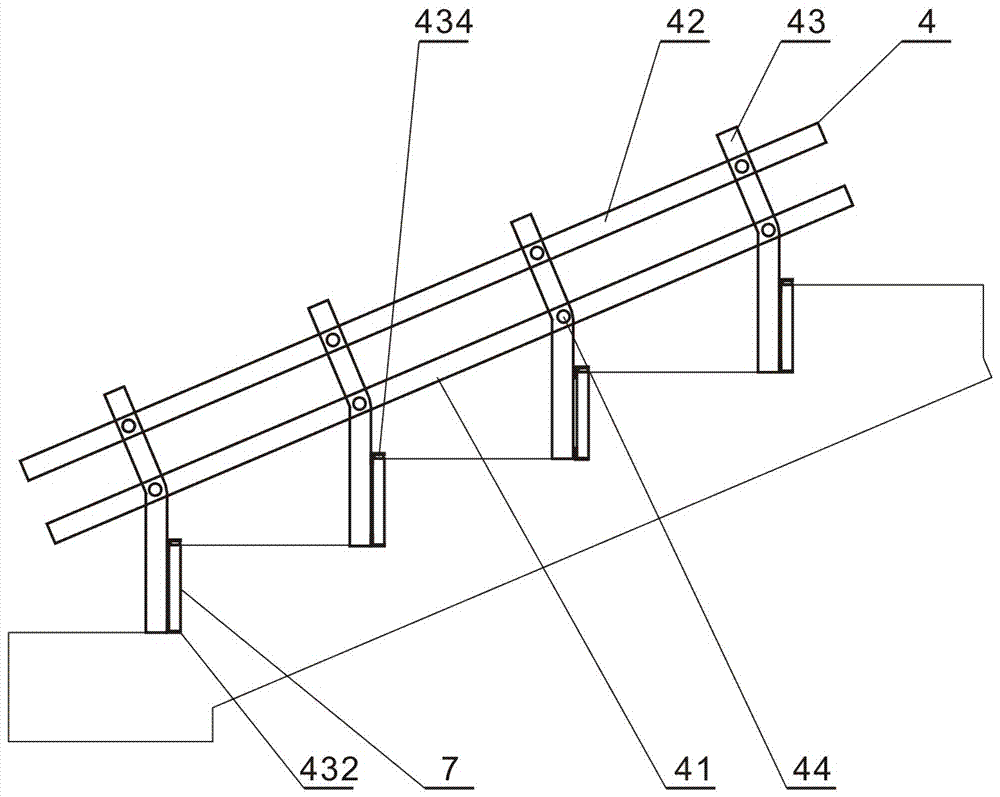

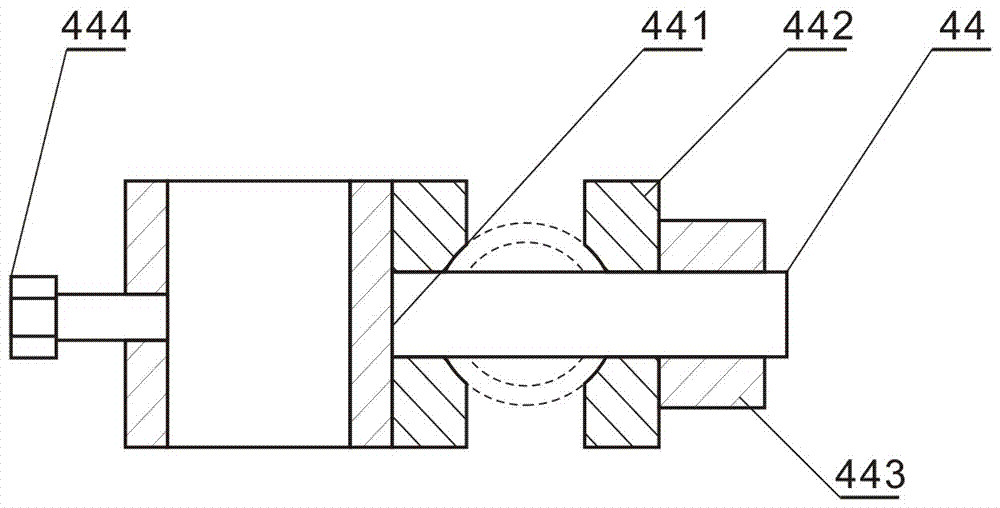

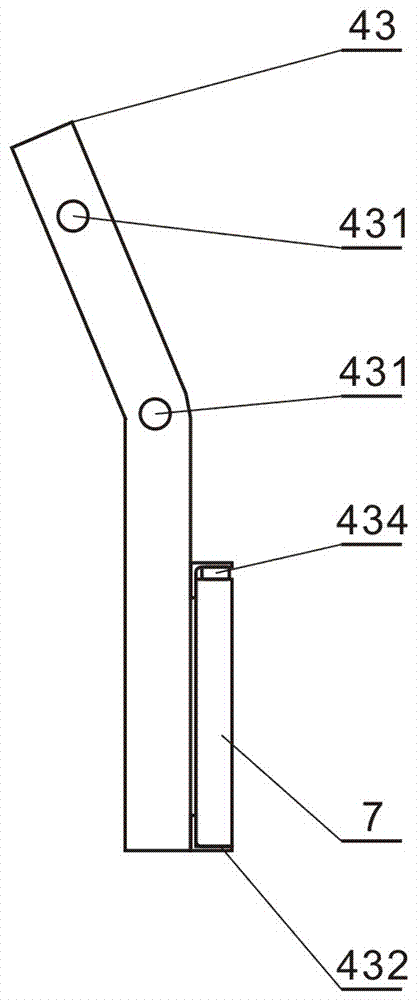

[0016] refer to figure 1 , figure 2 , image 3 , Figure 4 , the present invention comprises a step side panel 4, a horizontal bar 5, a cross fastener 6 and a step vertical plate 7, and the step side panel 4 is composed of a main longitudinal bar 41, an auxiliary longitudinal bar 42, a step adjustment bar 43 and a step joint 44 , the main longitudinal bar 41 and the auxiliary longitudinal bar 42 are arranged in parallel, and the stepping adjustment bars 43 are several pieces, and they are arranged in parallel with the main longitudinal bar 41 and the auxiliary longitudinal bar 42 to overlap in the shape of a "well", and the stepping joints 44 are several pieces, and respectively Hinge the overlapping nodes between the main longitudinal bar 41, the auxiliary longitudinal bar 42 and the step adjusting bar 43 sequentially;

[0017] The step side piece 4 is two pieces arranged side by side on both sides of the stair step, and the main longitudinal bar 41 and the secondary long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com