Efficient hollow turbine pump

A hollow, turbine technology, applied to pump devices, pumps, components of pumping devices for elastic fluids, etc., can solve problems such as low suction and discharge efficiency, debris and humidity sticking and blocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1: Such as: dredging, sewage, sand, dust, concrete, etc.

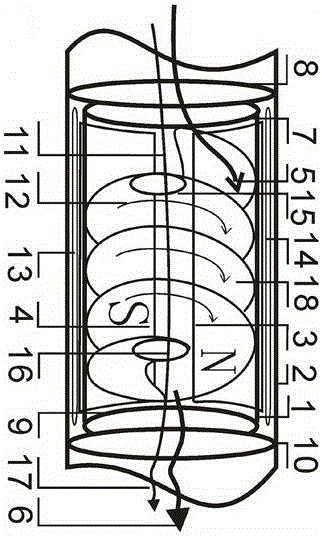

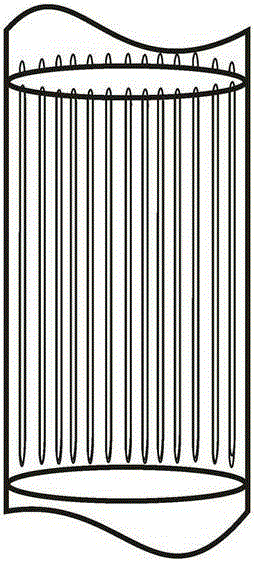

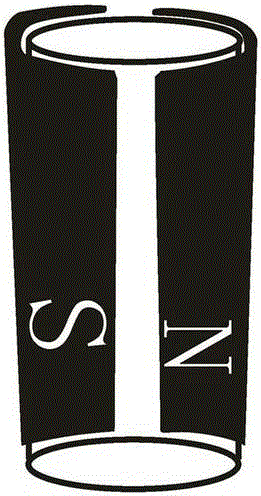

[0016] The inventive method consists of 1 hollow barrier-free turbine rotor, 2 pipeline stators and 18 hollow barrier-free turbines to form a suction-discharge motor pump.

[0017] Using the high-efficiency hollow turbine pump equipment, electromagnetic induction is used to drive the turbine of the motor to rotate to form a high-efficiency hollow turbine suction-discharge pump.

[0018] 1 The two ends of the barrier-free hollow turbine rotor are respectively provided with 7 inlet bearing inner walls and 9 outlet bearing inner walls and 3 rotor N poles are connected with 4 rotor S poles to form a turbine rotor; 2 The two ends of the pipeline stator are respectively provided with 8 inlet bearing outer walls and 10 outlets The outer wall of the bearing and the 13 stator S wire package and the 14 stator N wire package are connected to form the culvert tube stator; the 5-condition sand and gravel sludge is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com