Double-hydraulic energy flow dividing rotary vane power generation system

A power generation system and dual water technology, applied in hydropower, engine components, machines/engines, etc., can solve the problems of low water resource utilization, dangerous leakage of reservoir water tension dams, and high power generation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

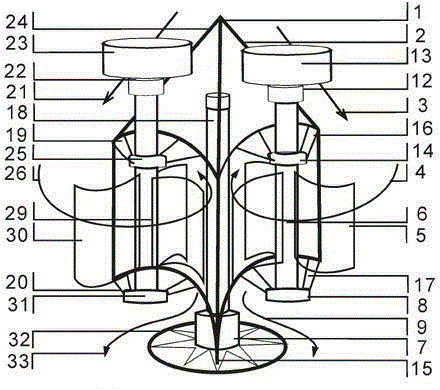

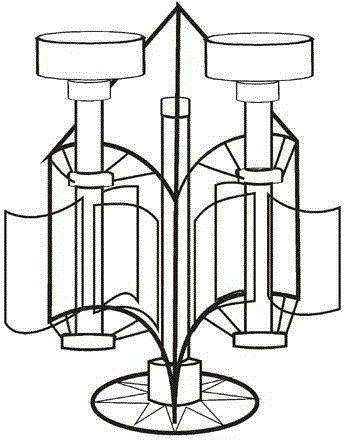

[0022] Such as: double water energy shunt rotary vane generator.

[0023] Utilize this two-water splitting rotary vane power generation system, set up a cow energy splitting device to form a vortex, which is used as power to drive the rotary vane of the generator to rotate to form a vortex rotary vane power generation; water potential energy thrust plus vortex torque force to mechanical energy to electrical energy.

[0024] The second group consists of 30 water-cutting and water-guiding smart rotary vanes, 1 pair of cow energy angular shunt devices and 23 generators to form a power generation system;

[0025] 30 water-cutting and water-guiding smart rotary blades are provided with 29 rotary blade couplings; 29 rotary blade couplings are provided with 31 lower end bearings and 31 lower end bearings are fixed externally; The bearing center is coaxial with the upper end bearing of 22, and the upper end bearing center of 22 runs through the generator rotor to form a vortex blade p...

Embodiment 2

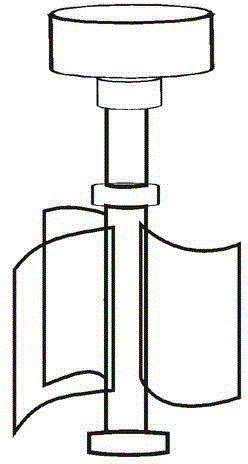

[0027] Such as: double water energy shunt rotary vane generator.

[0028] According to the method of the present invention, a set of power generation system is composed of 5 water-cutting and water-guiding intelligent rotary vanes, 1 pair of horn-shaped diversion devices and 13 generators;

[0029] The 5 water-cutting and water-guiding smart rotary vanes are equipped with 6 rotary vane couplings; 8 lower end bearings are arranged under the 6 rotary vane couplings and 8 lower end bearings are fixed externally; 14 upper end bearings are installed on the 6 rotary vane couplings to connect to the inner wall of the fixed bearing. The bearing center is coaxial with the 12 upper end bearing and the 12 upper end bearing center runs through the generator rotor to form a vortex swirl power generation device, and the generator rotor constitutes a power generation system; the 14 upper end is connected to the fixed bearing outer wall and the 16 upper end is connected and fixed, and the 1 N ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com