Efficient suction and exhaust hollow ring shaftless motor fan

A hollow ring, high-efficiency technology, used in mechanical equipment, machines/engines, non-variable-capacity pumps, etc., can solve problems such as large torque, easy corrosion motor power consumption, oil fume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Such as: range hood, exhaust fan

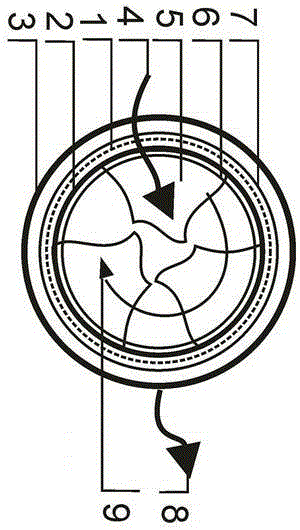

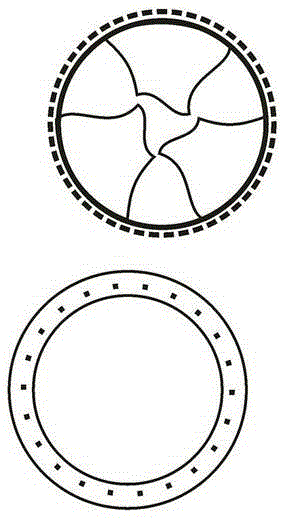

[0017] The method of the invention consists of a hollow ring stator, two hollow ring rotors and six rotary vane coaxial bearings to form a suction and discharge motor fan.

[0018] The high-efficiency suction and discharge hollow ring shaftless motor fan is used, and the motor is used as power to drive the rotating blades to form an energy-saving suction and discharge hollow ring fan.

[0019] 2 hollow ring rotors are connected in parallel with 6 rotors and the inner wall of the coaxial bearing is driven by 5 ring wall rotors to form a rotating suction and exhaust fan device; 2 hollow ring rotors are connected in parallel with 6 rotors and the inner wall of the coaxial bearing is energized through the outer wall of 7 bearings and 1 hollow ring stator to generate magnetic field line cutting. The rotation pushes the 5 ring wall rotary vanes to work.

[0020] 1. The hollow ring stator is connected to 7. the outer wall of the bearing and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com