Reversing valve used for conveying silica gel mill base

A reversing valve and color paste technology, applied in the field of reversing valves, can solve the problems of reversing valve failure, high viscosity of silica gel color paste, and easy adhesion on the inner wall of the channel inside the reversing valve, etc., to achieve structural Simple, reduce the effect of reversing valve clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

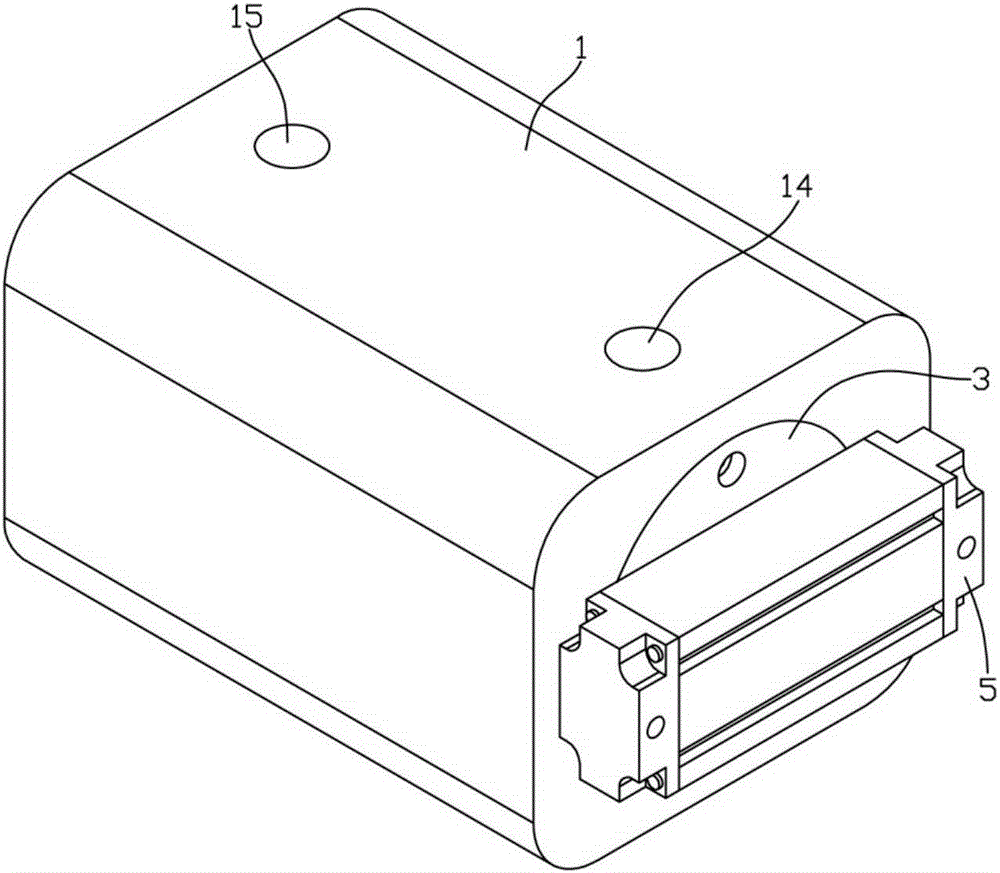

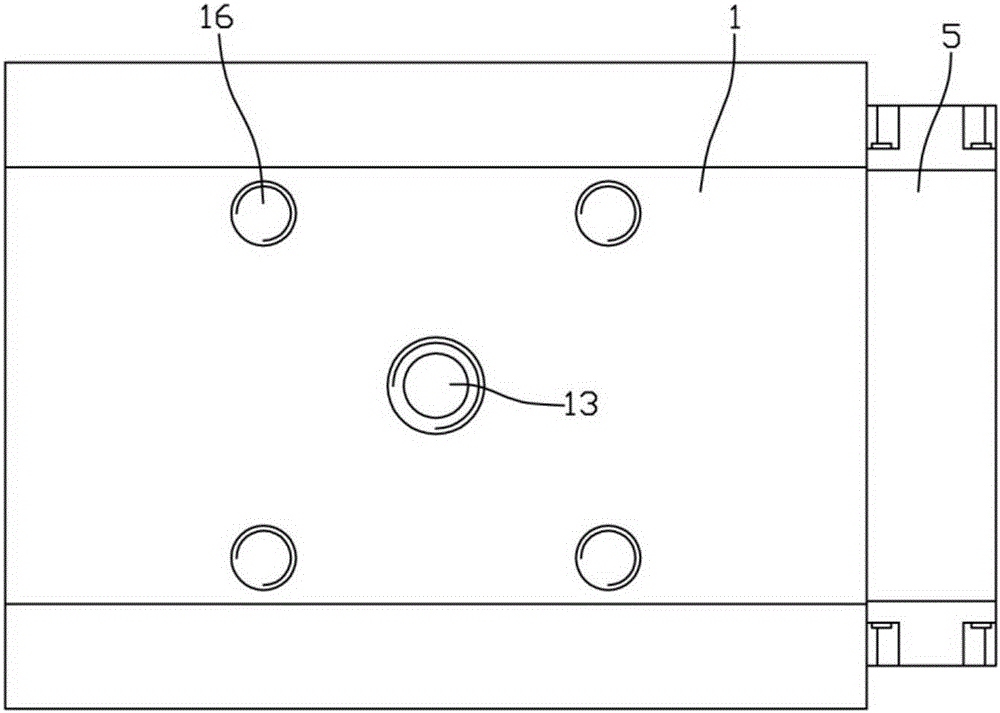

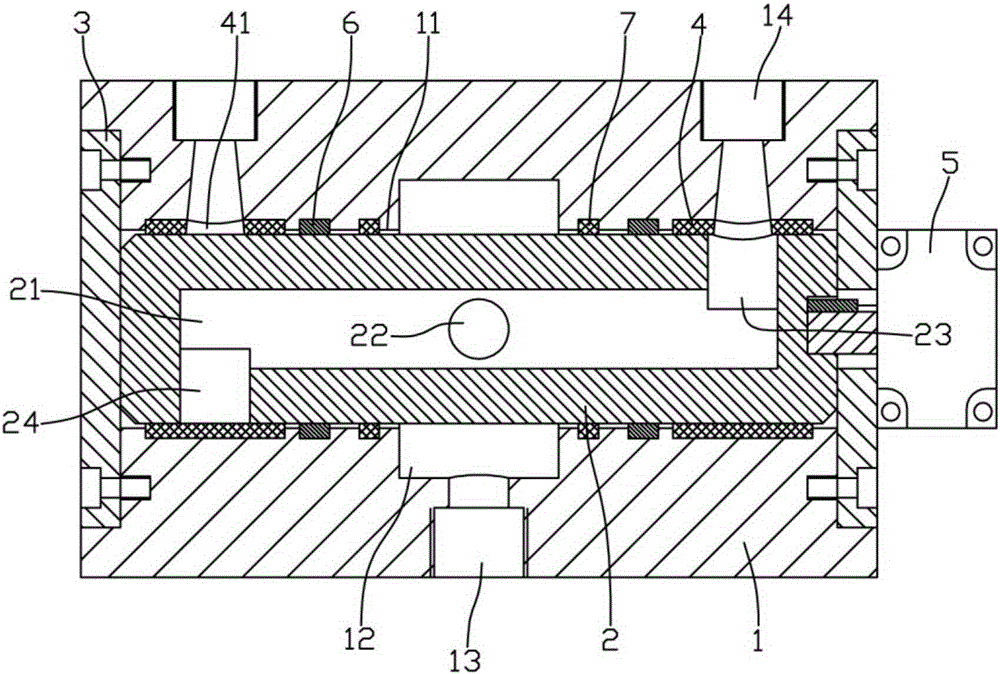

[0018] Example: see Figures 1 to 4 As shown in the figure, a reversing valve used for conveying silica gel color paste includes a valve seat 1 and a cylindrical valve core 2. The valve core hole 11 is formed on the valve seat 1 and runs through the end faces of the left and right sides, and the valve core hole 11 is inserted Connected with the valve core 2, an annular groove 12 is formed on the inner wall of the middle part of the valve core hole 11 of the valve seat 1, and a reversing hole 13 penetrating through the lower end surface of the valve seat 1 is formed on the inner wall of the annular groove 12, and on the inner wall at both ends of the valve core hole 11 The input hole 14 and the output hole 15 are respectively formed through the upper end surface of the valve seat 1; the left and right end surfaces of the valve core 2 are against the end cover 3, and the end cover 3 is fixedly connected to the left and right end surfaces of the valve seat 1;

[0019] A channel 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com