Compressor oil return control method, oil return device and air conditioner

A technology of oil return control and compressor, which is applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems that the oil return efficiency cannot be guaranteed, and the normal oil return of the inverter air conditioner can not be guaranteed, so as to reduce the number of gates , Improve working performance and reduce bypass loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

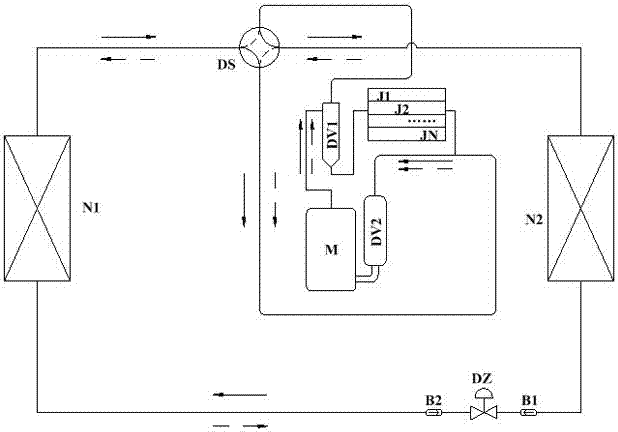

[0040] see figure 1 As shown, in the air conditioning system, under the action of the compressor M, the refrigerant is compressed from a low-temperature, low-pressure gaseous refrigerant into a high-temperature, high-pressure gaseous refrigerant, and is delivered to the refrigerant circulation pipeline through the exhaust port of the compressor M. When the air conditioning system works in cooling mode, the high-temperature and high-pressure gaseous refrigerant discharged through the compressor M first flows to the outdoor heat exchanger N2 through the four-way valve DS. In cooling mode, the outdoor heat exchanger N2 acts as a condenser to condense the gaseous refrigerant into liquid refrigerant, which is sent to the indoor heat exchanger N1 through the filter B1, electronic expansion valve DZ, and filter B2. The indoor heat exchanger N1 acts as an evaporator in the cooling mode, absorbs indoor heat, vaporizes the liquid refrigerant to form a gaseous refrigerant, and returns to...

Embodiment 2

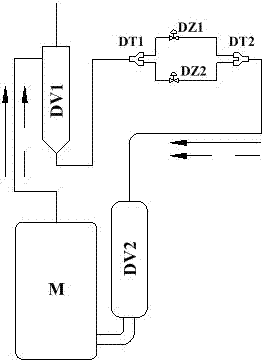

[0079] see image 3 As shown, the structural design of the compressor oil return device of this embodiment is basically the same as that of the first embodiment, the only difference being the structural design of the throttling pipeline. In this embodiment, the electronic expansion valves DZ1 and DZ2 are selected as throttling elements for the structural design of the throttling pipeline. Since the electronic expansion valve has both throttling and switching functions, when changing the gating status of each throttling pipeline, it is only necessary to control the opening or closing of the electronic expansion valve in the corresponding throttling pipeline.

[0080] based on image 3 The compressor oil return device shown can be controlled by the compressor oil return control method described in Embodiment 1, and this embodiment will not be further described here.

[0081] Although image 3 Only two throttling pipelines designed by using two electronic expansion valves DZ2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com