An ignition circuit applied to electric explosive device

An ignition circuit and device technology, applied in blasting and other directions, can solve the problems such as the ignition circuit cannot be ignited normally, the ignition sequence of the electric explosion device group fails, and the normally open contacts work asynchronously.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below with reference to the accompanying drawings and examples.

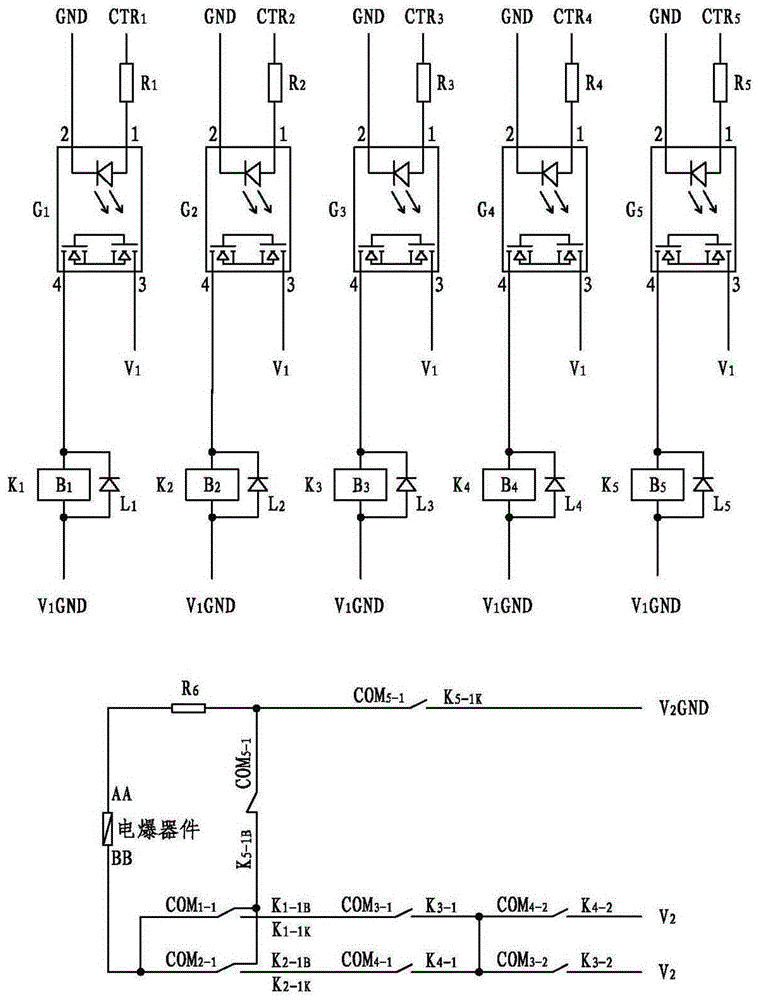

[0031] Such as figure 1 As shown, the ignition circuit in this embodiment includes five electromagnetic relays K 1 、K 2 、K 3 、K 4 and K 5 , five optocoupler relays G 1 , G 2 , G 3 , G 4 and G 5 , five freewheeling diodes L 1 , L 2 , L 3 , L 4 and L 5 , six current-limiting resistors R 1 , R 2 , R 3 , R 4 , R 5 and R 6 .

[0032] For electromagnetic relays, it includes multiple sets of normally open contacts and normally closed contacts, and each common terminal corresponds to a set of normally open contacts and a set of normally closed contacts. Just select the contact and its common terminal.

[0033] Electromagnetic relay K 1 with wire package B 1 , normally open contact K 1-1K and its corresponding public port COM 1-1 , normally closed contact K 1-1B and its corresponding public port COM 1-1 , and the normally open contact K ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com