Method and apparatus for producing radionuclide

一种放射性核素、制造方法的技术,应用在放射性核素制造装置领域,能够解决无法得到放射性比度等问题,达到高效制造的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

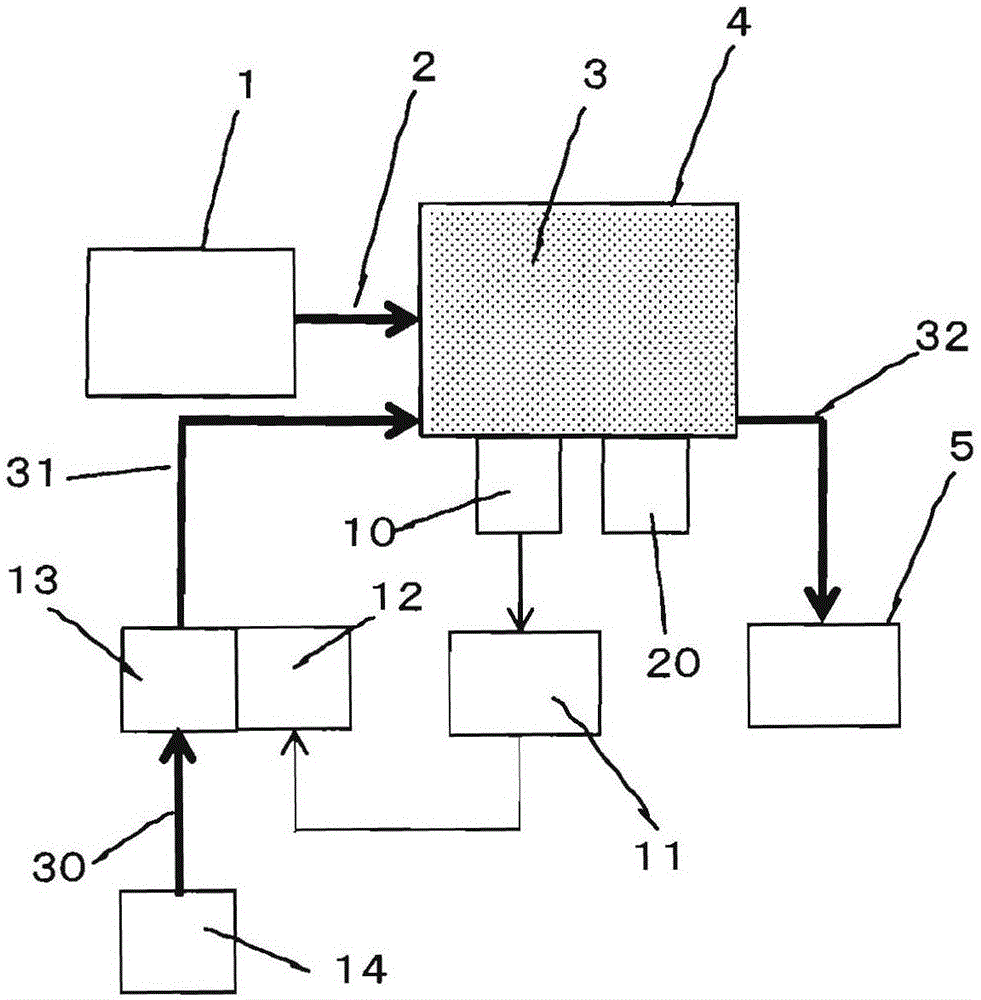

[0030] based on figure 1The structure of the radionuclide production apparatus of Example 1 which is a preferred example of the present invention will be described.

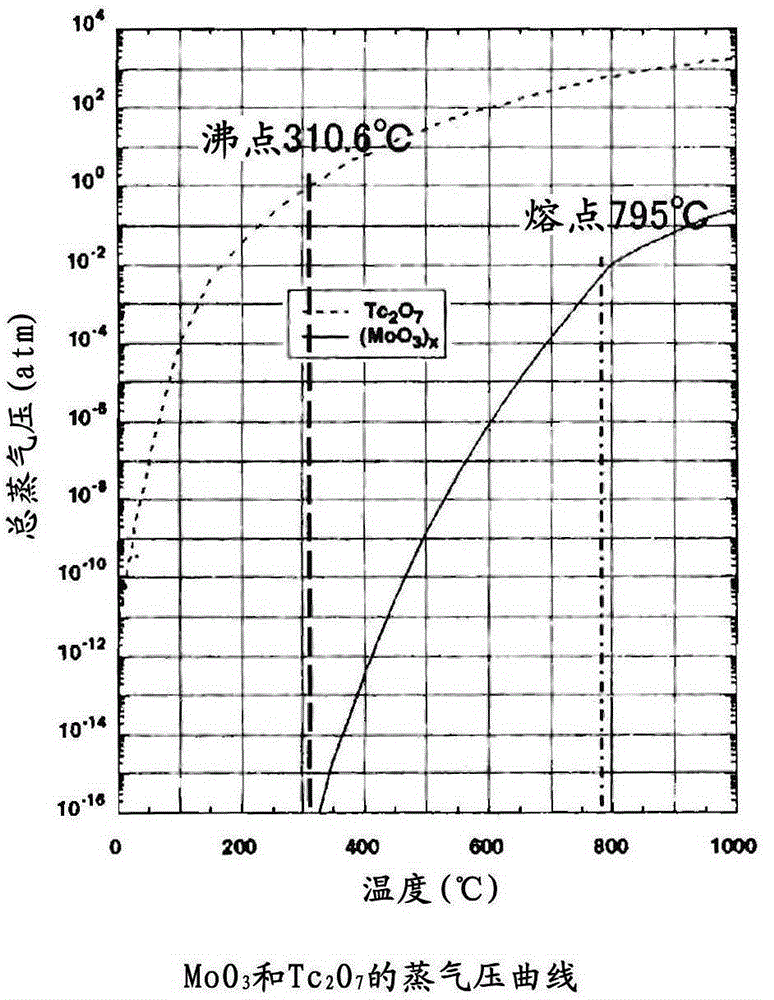

[0031] The radionuclide manufacturing device of this embodiment is as figure 1 As shown, it is equipped with an electron beam accelerator 1, a test container 4 containing a raw material 3 for radionuclide production, a radionuclide separation and purification device 5, a thermometer 10, a heating / cooling control device 11, a heating / cooling device 12, a heating / cooling device Cooling unit 13, gas supply device 14, vibration device 20, and control system (not shown). The raw material 3 for producing a radionuclide contains a raw material nuclide which becomes a raw material of the produced radionuclide. In this embodiment, as the raw material for radionuclide production, molybdenum trioxide 100 (Mo-100 O 3 ) powder sample 3 will be described as an example. Molybdenum trioxide 100 (Mo-100 O 3 ) The temperature...

Embodiment 2

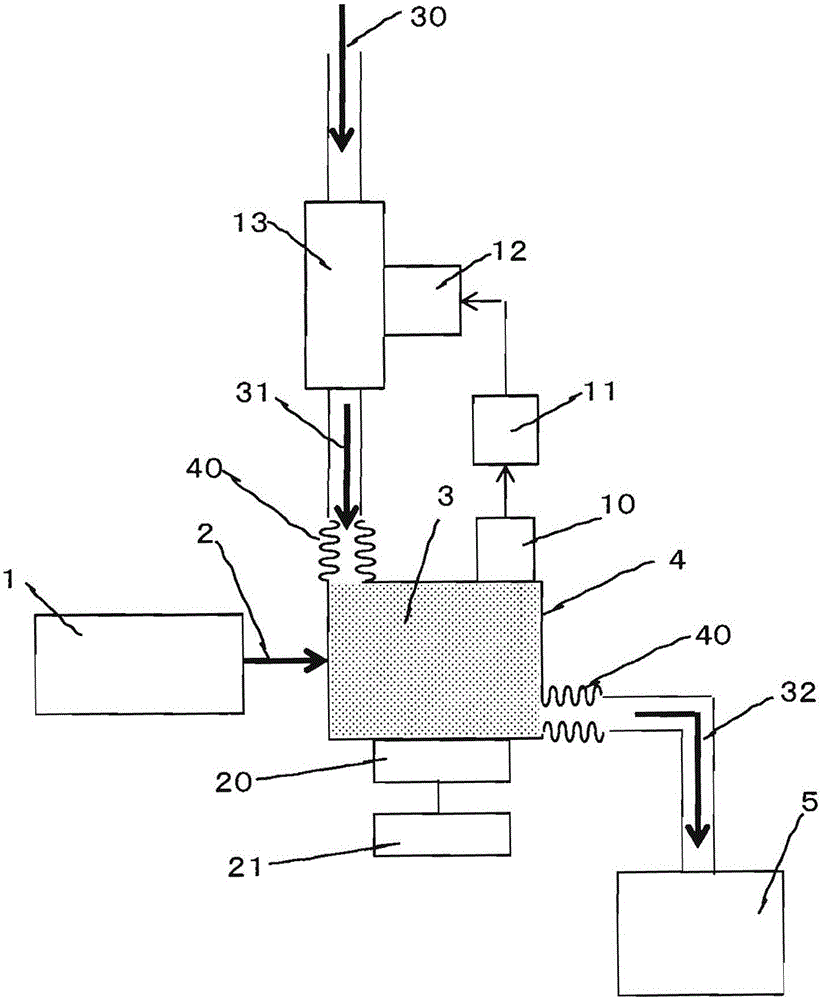

[0038] based on image 3 The structure of the radionuclide production apparatus of Example 2 which is a preferred example of the present invention will be described. The basic structure of the radionuclide production apparatus of this example is the same as that of the radionuclide production apparatus of Example 1, but the structure of the joint portion 40 connecting the pipe and the sample container through a bellows-shaped pipe is the same as that of the radionuclide production apparatus of Example 1. The manufacturing device is different, and the joint part 40 is connected to the piping that flows through the mixed gas 31 of heated or cooled oxygen or oxygen and inert gas, and the piping connected to the separation and refining device, and the installation of molybdenum trioxide 100 (Mo-100·O 3 ) The container part 4 of the powder sample is connected. Hereinafter, the description will focus on the configuration different from that of the first embodiment.

[0039] The vi...

Embodiment 3

[0042] based on Figure 4 The structure of the radionuclide production apparatus of Example 3, which is a preferred example of the present invention, will be described. The basic structure of the radionuclide manufacturing apparatus of this embodiment is the same as that of the radionuclide manufacturing apparatus of Embodiment 2, but for the piping through which the temperature-regulated oxygen or the mixed gas 31 of oxygen and inert gas flows, in the heating / cooling section 13 is different from the radionuclide manufacturing apparatus of the second embodiment in that the coiled heating and cooling piping 60 is provided therein. Like the radionuclide production apparatus of this embodiment, by providing the heating and cooling piping 60 wound into a coil shape in the heating and cooling unit 13, the flow of oxygen or the mixed gas 30 of oxygen and inert gas can be extended for heating and cooling. Ministry time.

[0043] In addition, in the radionuclide manufacturing device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com