Miniature spiral pipeline robot

A technology of spiral pipes and robots, applied in the field of robots, can solve the problems of large traction force and small size, and achieve the effect of large traction force and flexible movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

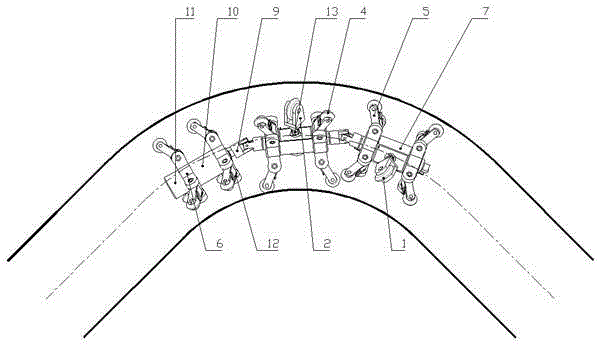

[0019] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

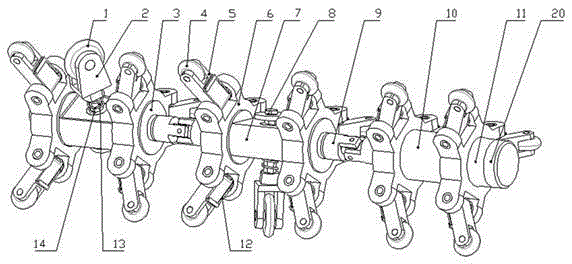

[0020] The invention relates to a miniature spiral pipeline robot, which includes a driving sub-joint and a moving sub-joint.

[0021] Described driving joint comprises driving motor 10, power supply 20, controller 11 and righting mechanism; Elastic force is provided to make the guide wheel 4 closely contact with the pipeline; the righting mechanism is composed of the guide wheel frame 6, the guide wheel arm 5, the guide wheel 4, and the torsion spring 12; the righting mechanism can keep the motor in the center of the pipeline and balance the reverse torque.

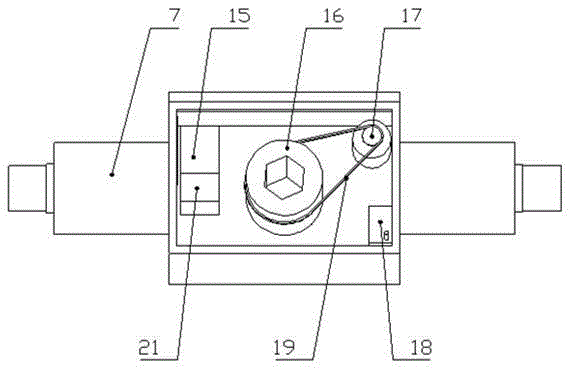

[0022] Described kinematic joint comprises body 7, driving wheel 1, driving wheel frame 2, reducing rod 13, spring 14, angle adjustment sleeve 16, angle adjustment motor 17, transmission mechanism 19, battery 21, single-section controller 18 and by Guide wheel frame 6, guide wheel arm 5, guide wheel 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com